Method for continuously washing coal ash under coal bed methane well in bride type without causing pollution

A non-polluting technology for coalbed methane wells, which can be used in flushing boreholes, drilling equipment, earthwork drilling, etc., and can solve the problems of high cost, unsuitable cleaning of highly deviated wells, and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

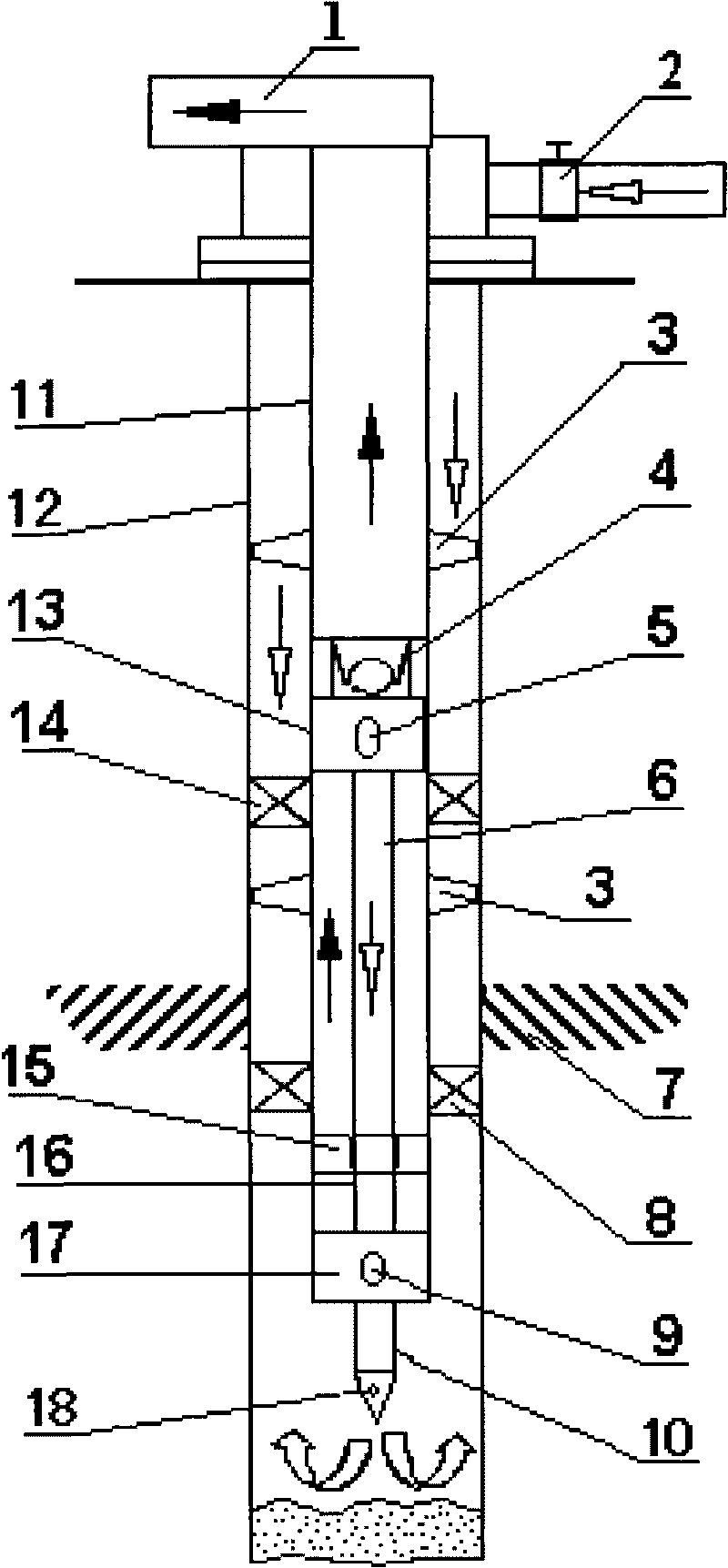

[0045] Embodiment 1: Taking a coalbed gas well bridge-type pollution-free continuous flushing coal ash process string as an example, the present invention will be further described in detail.

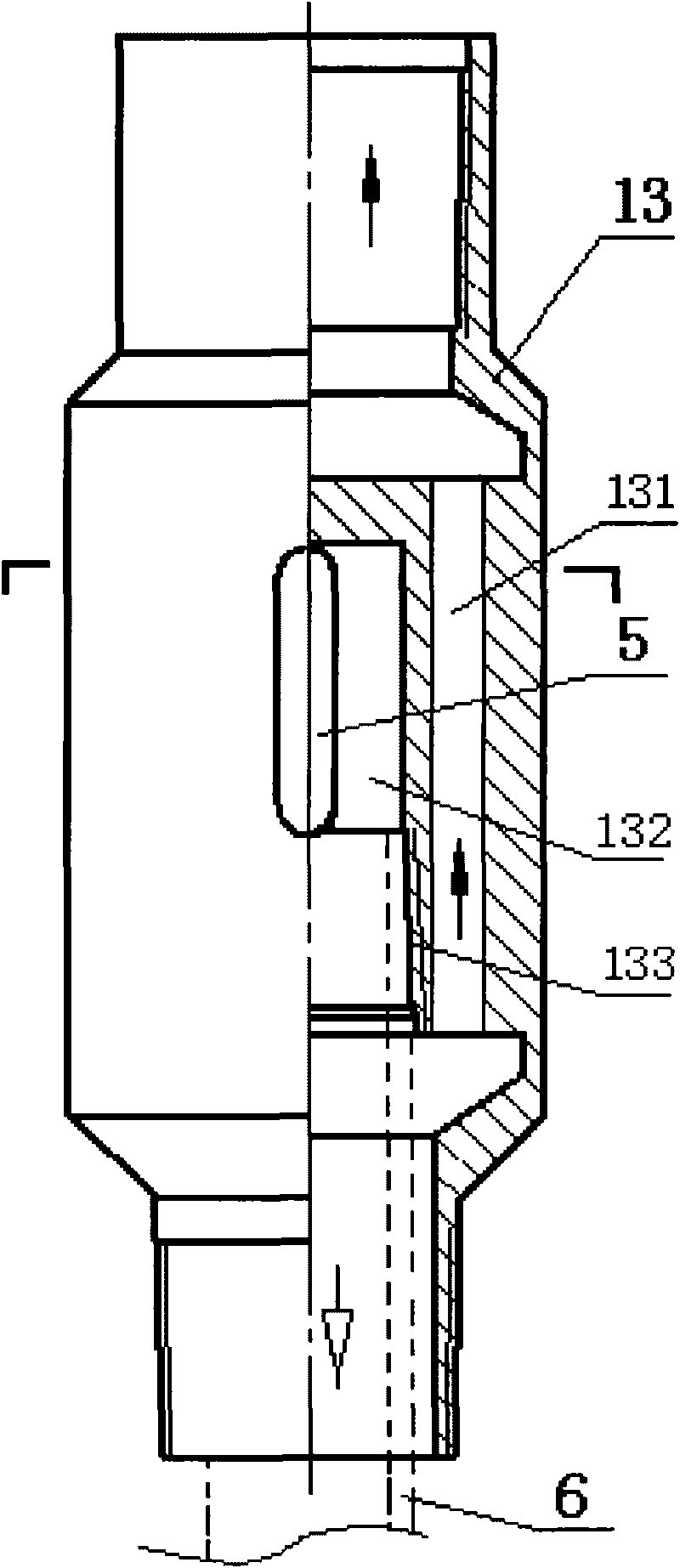

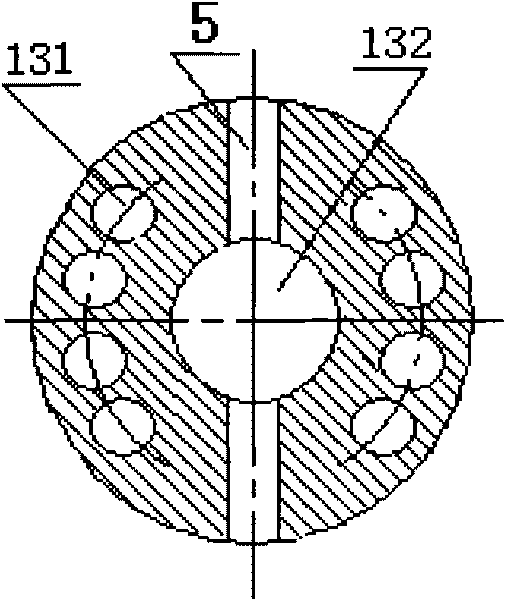

[0046] refer to figure 1 . The coal bed gas well bridge type pollution-free continuous flushing coal ash process pipe string of the present invention mainly consists of oil pipe 11, check valve 4, upper bridge 13, upper packer 14, lower packer 8, upper intubation pipe 6, special joint 15, the lower bridge 17 and the retractable pulverized coal spray nozzle 10 are formed.

[0047] The nominal diameter of the oil pipe 11 is 62 mm. Two tubing centralizers 3 are respectively connected above and below the upper packer 14, and the model of the centralizers 3 is FZQ-φ114. The lower part of the oil pipe 11 is connected with a check valve 4, and the check valve 4 is used to prevent the rubber sleeve of the rubber cup packer from being worn down when the pipe string is used in a deviated well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com