Compound damping layer vibration attenuation piece for noise reduction of disc type brake

A disc brake and compound damping technology, which is applied to the components of the brake, the type of the brake, the brake actuator, etc., can solve the problem that the active noise reduction is not suitable, the problem is complex, the occurrence mechanism and the analysis method are not very consistent. and other problems to achieve the effect of increasing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

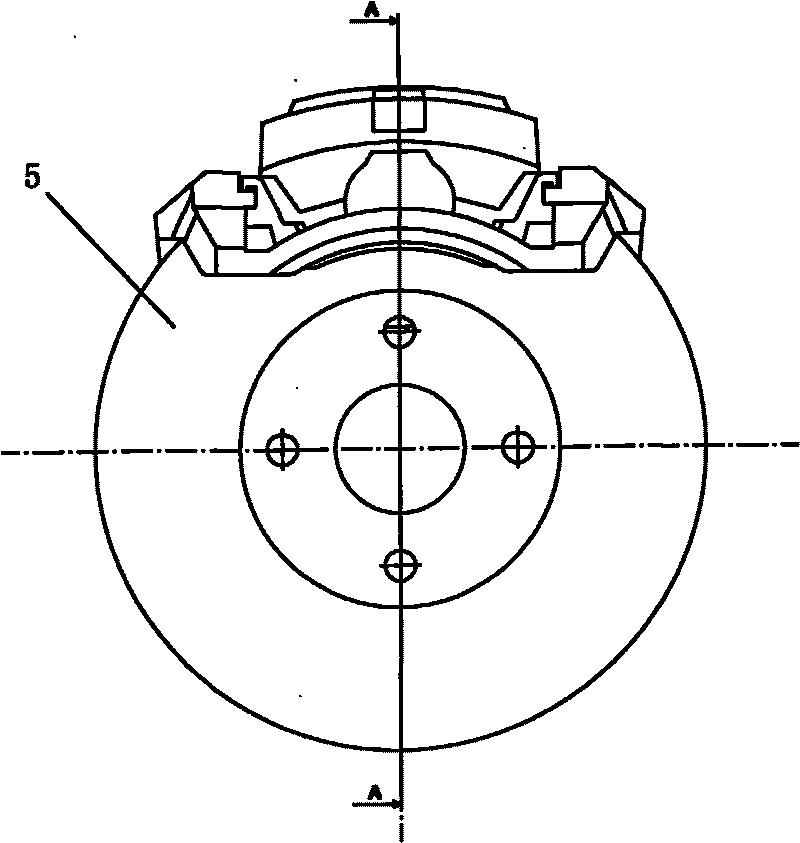

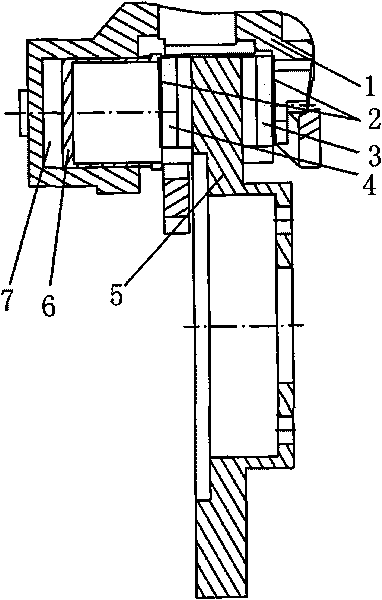

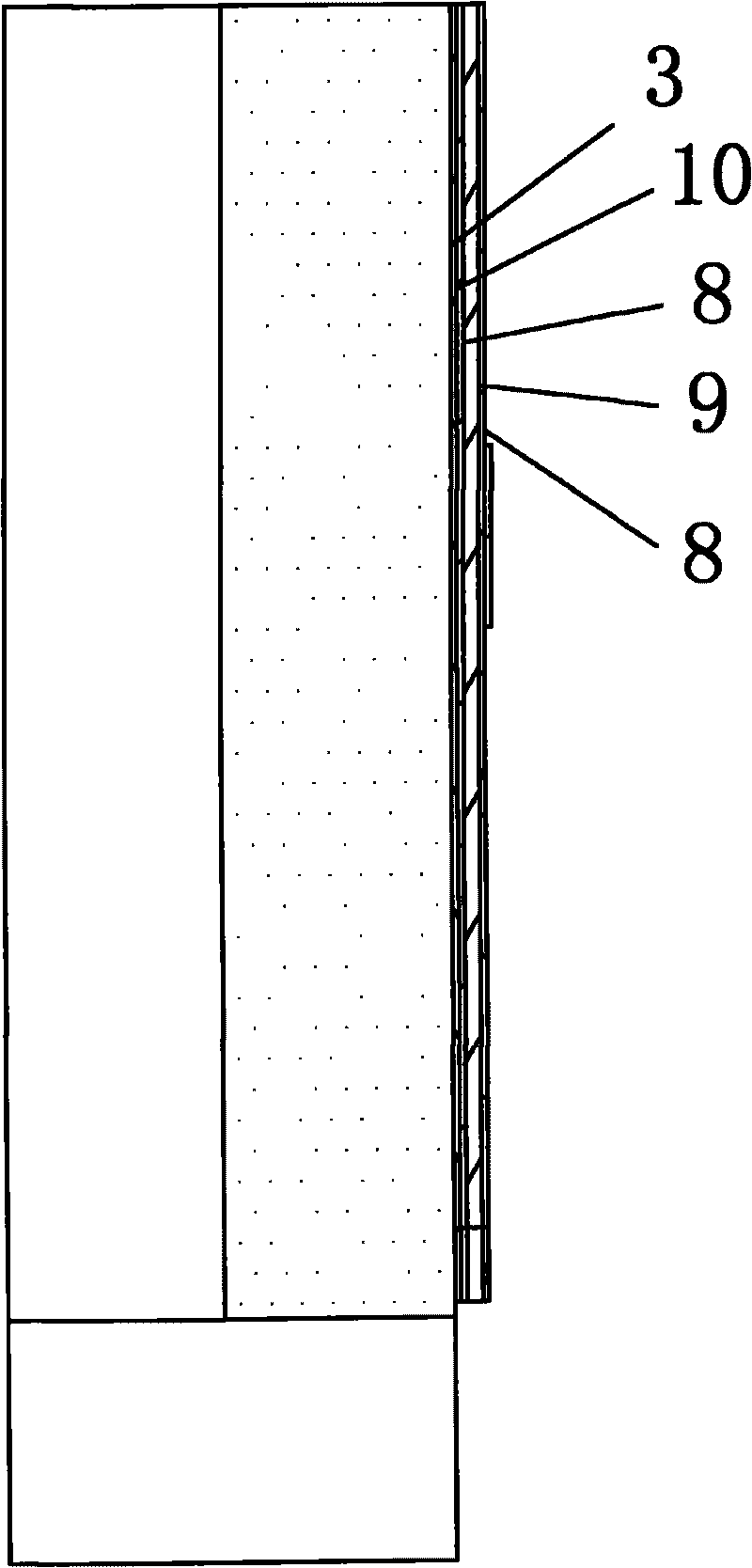

[0017] As shown in the figure, this kind of composite damping layer shock absorber for disc brake noise reduction mainly includes a brake caliper 1, an outer brake block 3, an inner brake block 4, a brake disc 5 and a piston 6. The two sides of the moving disc 5 are respectively provided with an outer brake block 3 and an inner brake block 4, the outer side of the outer brake block 3 is provided with a brake caliper 1, the outer side of the inner brake block 4 is provided with a piston 6, and the outer side of the piston 6 is provided with a brake caliper 1. Hydraulic oil 7 is provided, and damping sheets 2 are provided between the outer brake block 3 and the brake caliper 1 and between the inner brake block 4 and the piston 6. The shock absorbing sheet 2 is mainly composed of a steel plate 9 and a rubber coating 8 Composed of high molecular polymer coating 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com