System for quickly measuring surface quality

A surface quality and measurement system technology, applied in measurement devices, instruments, optical devices, etc., can solve the problem of relatively high requirements on the anti-interference ability of the measurement system, and achieve the effect of low cost and improved measurement speed.

Inactive Publication Date: 2011-01-05

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On-line measurement often needs to be carried out in a relatively obvious processing environment such as vibration and air disturbance, so the anti-interference ability of the measurement system is relatively high, and the general optical interferometer is incompetent; at the same time, in order to shorten production time and improve processing efficiency , it is required that the interferometric method should be able to complete in a short period of time, preferably within a few seconds, which poses a challenge to both white light interferometers and wavelength scanning interferometers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

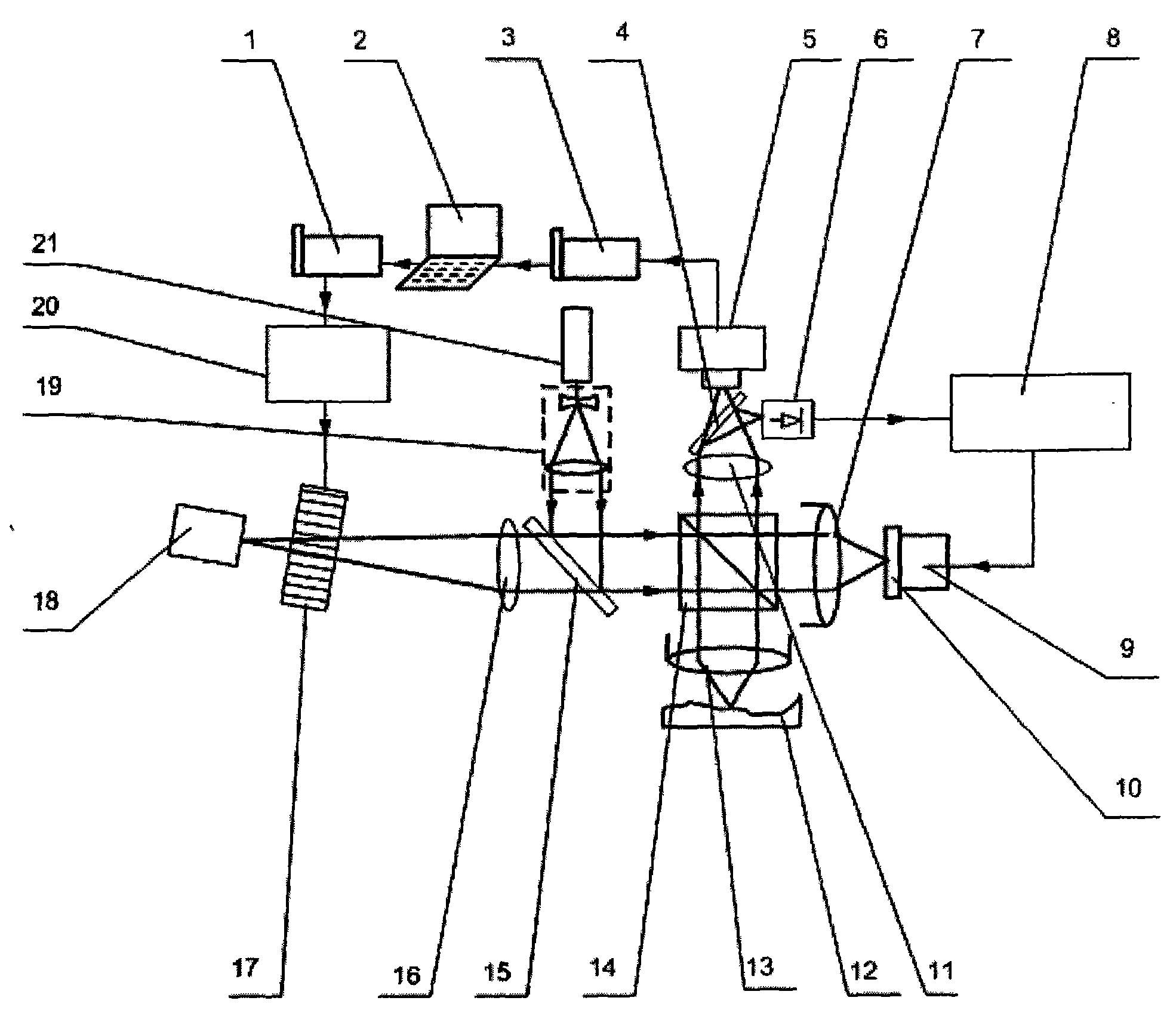

The invention discloses a system for quickly measuring surface quality. The system comprises two sets of common-path interferometers, wherein one set of reference interferometer for noise compensation is specially used for detecting noises such as vibration, air disturbance and the like in environment, and eliminating the influence of interference of the background noises through negative feedback; and the other set of main interferometer for measurement controls wavelength of optical wave incident to the interferometers by using an acousto-optic filter, and can quickly acquire a three-dimensional feature of a surface to be measured by processing a generated interference signal by using large-scale parallel computation based on GPGPU. The system can measure the surface quality in real time, does not need mechanical light path scanning in the process of measurement, and can reach a high measurement speed. The system can be updated one time in 1 to 2 seconds on average, and can be updated more frequently after being optimized. The system can reduce influence of environmental noise on the measurement by adding the active optical path compensation technology, achieves measurement accuracy of sub-nano range, reduces cost, saves a usually expensive high-precision translation stage and can be used for processing workshops with more interference.

Description

A Rapid Surface Quality Measurement System technical field The invention relates to an optical measuring instrument, in particular to a fast surface quality measuring system. Background technique Surface quality testing affects the performance of most industrial products. According to surveys, more than 90% of engineering component failures start from the surface. Therefore, in the process of product processing, the detection of surface quality, including surface shape, waviness, roughness, etc., can accurately control the processing procedure so that the product can obtain the best quality and service life, and reduce the scrap rate. For high-precision machining, online measurement is particularly important. In addition, online surface inspection can also detect the wear condition of the machining tool in time and replace it before it is damaged. Due to the environmental restrictions in the processing process, it is generally required that the online detection method mu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/00G01B11/30G01B9/02

Inventor 汪凯巍杨将新曹衍龙金鹭汪琛琛

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com