Sludge deep dehydration method

A deep dehydration and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low dehydration efficiency and low sludge dewatering rate, achieve fast dehydration speed, high filter cake dehydration rate, and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

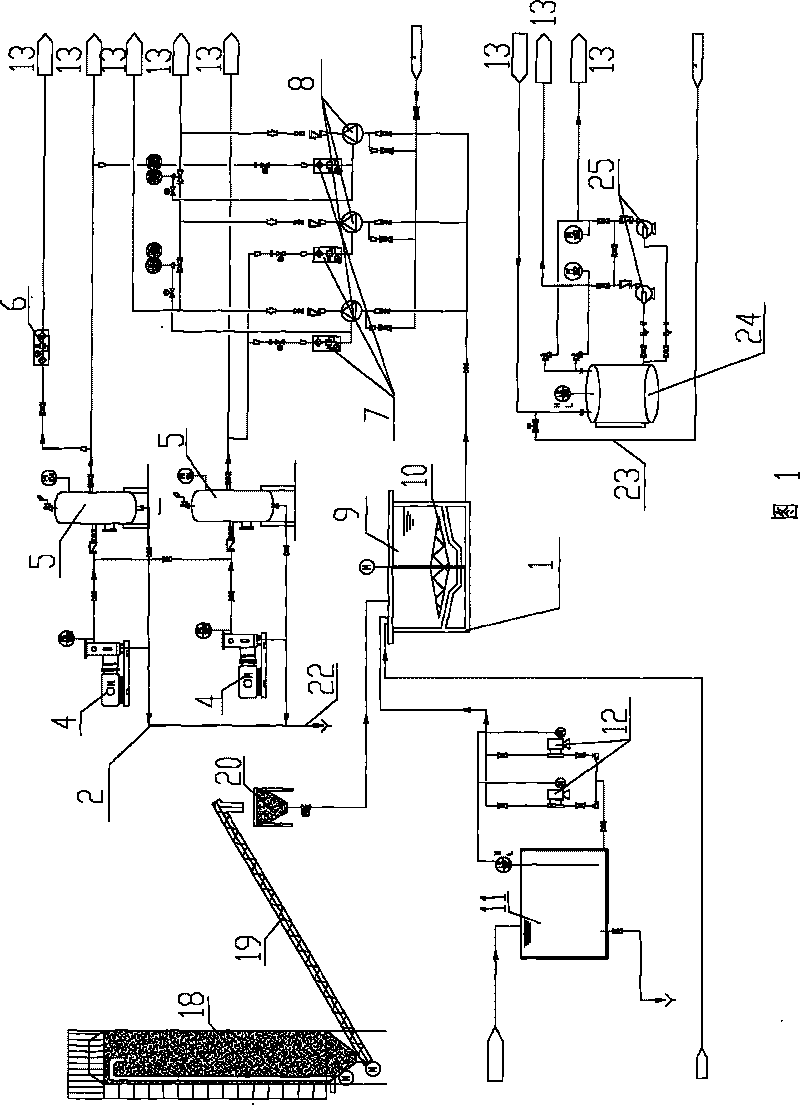

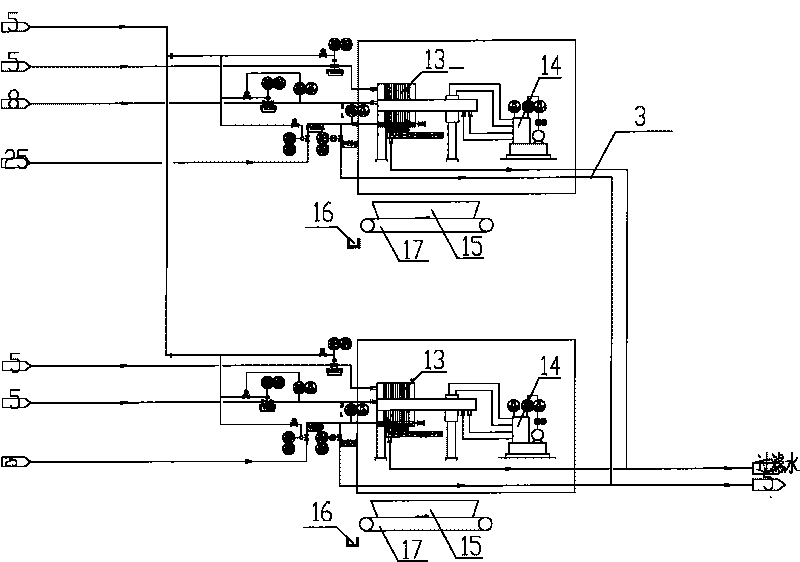

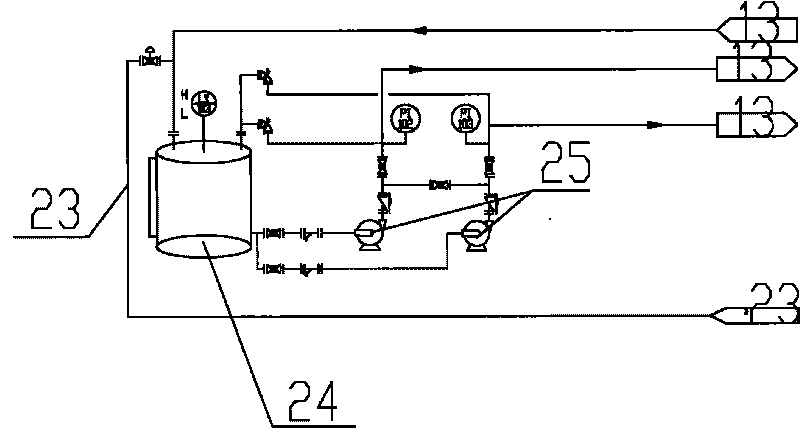

[0011] Embodiment 1: with reference to attached Figure 1~3 . A sludge deep dehydration method, which includes a dehydrating agent addition system 1, an air filtration treatment system 2 and a filtration dehydration system 3, a feed pump 8 is provided between the dehydration agent addition system 1 and the air filtration treatment system 2 and passes through The pipeline is connected, the air filtration treatment system 2 is connected to the filtration and dehydration system 3 through pipelines, and the filtered water outlet 21 of the filtration and dehydration system 3 is connected to the water inlet of the service water supply system 23, and the dehydration machine 13 dehydration machine in the filtration and dehydration system 3 There is a variable filter chamber diaphragm to press the filter cake, and a mud guide bucket 15 and a water outlet 16 are provided at the bottom of the dehydrator 13, and the mud guide bucket 15 is installed on the conveyor 17. Described dehydrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com