Nylon membrane and waterproof and moisture permeable cloth attached by same

A waterproof, moisture-permeable, nylon membrane technology, used in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as non-recycling and environmental pollution, and achieve the effect of solving recycling and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of nylon film, its processing method:

[0021] Add 100 grams of modified nylon resin, 20 grams of silicon compound with an average particle size of 15 μm, and 400 grams of solvent into an empty container, stir at high speed (500-1500 rpm), and then add 5 grams of additives and stir evenly.

[0022] Apply the adjusted solution evenly on the surface of the release paper using a coating machine to control the range of thickness variation. After drying at 50°C for 2 minutes and 120°C for 2 minutes, the film is formed, and the film is peeled off with a special peeling machine. Peel it off to test its performance.

[0023] In the above steps, use a coating machine to evenly coat the solution on the surface of the release paper, and control the range of thickness variation to obtain films with different thicknesses. For example, the average thicknesses of films with different thicknesses are 18.0 μm, 29.6 μm, 38.0 μm. The elongation of the film is between 50% and 400%...

Embodiment 2

[0035] A waterproof and moisture-permeable fabric laminated with nylon membrane

[0036] The nylon film with a thickness of 18.0 μm and the ordinary nylon woven fabric are passed through the dotted rolls of the laminating machine, and the adhesive is evenly transferred to the produced film, and then the nylon cloth and the nylon film are bonded together by the rolls. The measured properties are shown in the table below:

[0037] water pressure

(mmH 2 O)

(g / m 2 24h)

Peel strength

(N / cm)

17030

5187

3.20

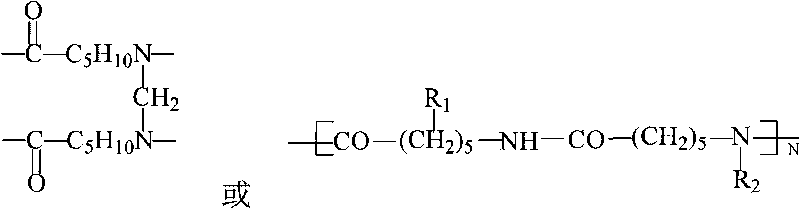

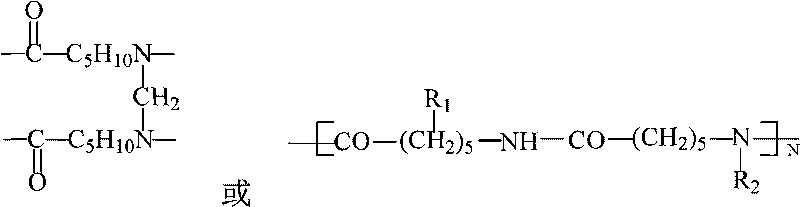

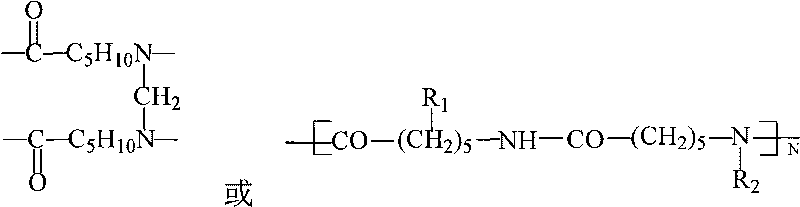

[0038] The modified nylon in the embodiment of the present invention 1 can also be following structure:

[0039]

[0040] in, or H,

[0041] R2=-CH 2 OCH 3 Or H, one or more of them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com