Waterproof TPU composite material and preparation method thereof

A composite material and polymer layer technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problem of low tensile strength, tear strength and mechanical strength of TPU waterproof and breathable membrane, weak waterproof and moisture permeability, etc. Problems, to achieve good breathability and moisture permeability, strengthen waterproof performance and barrier performance, improve waterproof performance and barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

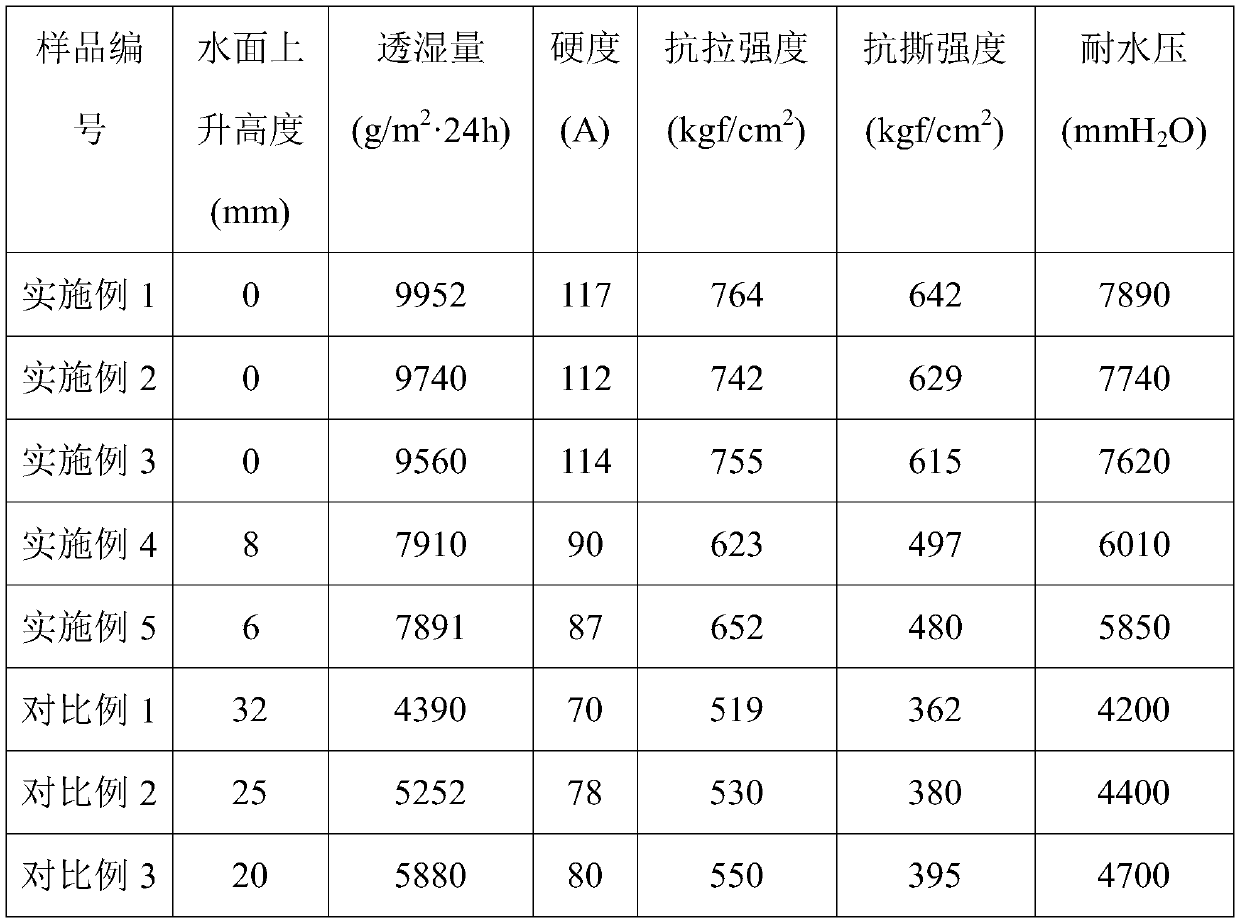

Examples

Embodiment 1

[0035] A waterproof TPU composite material, comprising a two-layer structure, the outer layer is a waterproof TPU polymer layer, the inner layer is a TPU film layer, and the waterproof TPU polymer layer is formed by interweaving warp threads and weft threads, and the warp threads are The mixture of polyurethane fiber and graphene fiber, described weft is silver fiber, and the mass ratio of described polyurethane fiber and graphene fiber is 2:1, and the mass ratio of described polyurethane fiber and silver fiber is 5:1, and described The texture of the waterproof TPU polymer layer is twill, and the thickness ratio of the outer layer to the inner layer is 1:3.

[0036] The concrete method of described waterproof TPU composite material comprises the following steps:

[0037] (1) Polyurethane fiber and graphene fiber mass ratio is 2:1 to mix uniformly as warp thread, is the silver fiber that the mass ratio of polyurethane fiber and silver fiber is 5:1 is weft thread, takes twill w...

Embodiment 2

[0040] A waterproof TPU composite material, comprising a two-layer structure, the outer layer is a waterproof TPU polymer layer, the inner layer is a TPU film layer, and the waterproof TPU polymer layer is formed by interweaving warp threads and weft threads, and the warp threads are The mixture of polyurethane fiber and graphene fiber, described weft is silver fiber, and the mass ratio of described polyurethane fiber and graphene fiber is 1:1, and the mass ratio of described polyurethane fiber and silver fiber is 8:1, and described The texture of the waterproof TPU polymer layer is twill, and the thickness ratio of the outer layer to the inner layer is 1:3.

[0041] The concrete method of described waterproof TPU composite material comprises the following steps:

[0042] (1) Mix the polyurethane fiber and graphene fiber mass ratio of 1:1 as the warp yarn, the silver fiber with the polyurethane fiber and silver fiber mass ratio of 8:1 as the weft yarn, take the twill weave as ...

Embodiment 3

[0045] A waterproof TPU composite material, comprising a two-layer structure, the outer layer is a waterproof TPU polymer layer, the inner layer is a TPU film layer, and the waterproof TPU polymer layer is formed by interweaving warp threads and weft threads, and the warp threads are The mixture of polyurethane fiber and graphene fiber, described weft is silver fiber, and the mass ratio of described polyurethane fiber and graphene fiber is 3:1, and the mass ratio of described polyurethane fiber and silver fiber is 8:1, and described The texture of the waterproof TPU polymer layer is twill, and the thickness ratio of the outer layer to the inner layer is 1:5.

[0046] The concrete method of described waterproof TPU composite material comprises the following steps:

[0047] (1) Mix polyurethane fiber and graphene fiber with a mass ratio of 3:1 as warp yarn, use polyurethane fiber and silver fiber mass ratio as 8:1 silver fiber as weft yarn, and use twill weave as texture to weave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com