Waterproof fiber knitted fabric and preparation method thereof

A technology of knitted fabrics and fibers, applied in knitting, warp knitting, plant fibers, etc., can solve problems such as easy generation of static electricity, poor waterproof and air permeability, poor flame retardancy of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

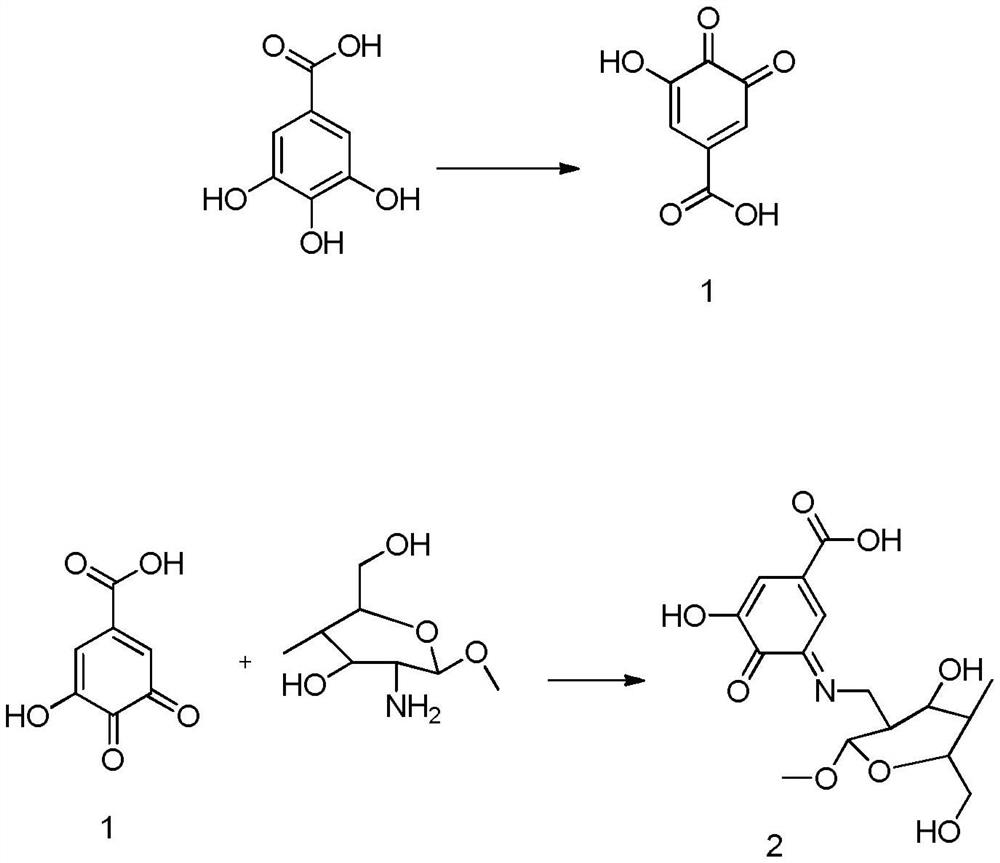

Method used

Image

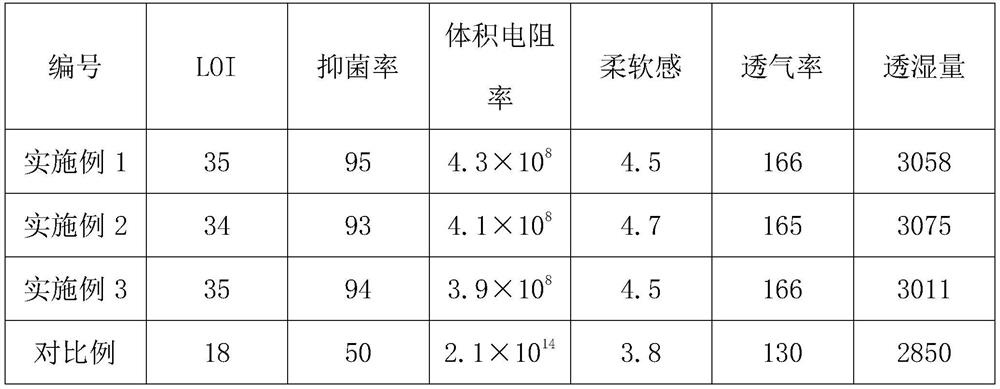

Examples

Embodiment 1

[0036] A preparation method of waterproof fiber knitted fabric is made by the following steps:

[0037] The first step is to manufacture gray cloth, using modified PTT fiber, aramid fiber, modified cotton fiber and bamboo fiber to interweave into gray cloth according to the mass ratio of 1:1:1:1, and the surface layer is made of modified PTT fiber and aramid fiber Fiber, the inner layer is made of modified cotton fiber and bamboo fiber;

[0038] The second step, pre-shrinking, dyeing, and setting, pre-shrinks and dyes the greige cloth obtained in the first step, and finally coats the coating agent on the surface layer to cure and set the shape, so as to obtain the waterproof fiber knitted fabric.

[0039] The preparation method of described coating agent comprises the following steps:

[0040] Step S11, add 1-butyl-3-methylimidazolium chloride and ethylene glycol into the reaction kettle, stir at a speed of 80r / min for 10min, then add copper chloride dihydrate into the reacti...

Embodiment 2

[0054] A preparation method of waterproof fiber knitted fabric is made by the following steps:

[0055] The first step is to manufacture gray cloth, using modified PTT fiber, aramid fiber, modified cotton fiber and bamboo fiber to interweave into gray cloth according to the mass ratio of 1:1:1:1, and the surface layer is made of modified PTT fiber and aramid fiber Fiber, the inner layer is made of modified cotton fiber and bamboo fiber;

[0056] The second step, pre-shrinking, dyeing, and setting, pre-shrinks and dyes the greige cloth obtained in the first step, and finally coats the coating agent on the surface layer to cure and set the shape, so as to obtain the waterproof fiber knitted fabric.

[0057] The preparation method of described coating agent comprises the following steps:

[0058] Step S11, add 1-butyl-3-methylimidazolium chloride and ethylene glycol into the reaction kettle, stir at a speed of 80r / min for 10min, then add copper chloride dihydrate into the reacti...

Embodiment 3

[0072] A preparation method of waterproof fiber knitted fabric is made by the following steps:

[0073] The first step is to manufacture gray cloth, using modified PTT fiber, aramid fiber, modified cotton fiber and bamboo fiber to interweave into gray cloth according to the mass ratio of 1:1:1:1, and the surface layer is made of modified PTT fiber and aramid fiber Fiber, the inner layer is made of modified cotton fiber and bamboo fiber;

[0074] The second step, pre-shrinking, dyeing, and setting, pre-shrinks and dyes the greige cloth obtained in the first step, and finally coats the coating agent on the surface layer to cure and set the shape, so as to obtain the waterproof fiber knitted fabric.

[0075] The preparation method of described coating agent comprises the following steps:

[0076] Step S11, add 1-butyl-3-methylimidazolium chloride and ethylene glycol into the reaction kettle, stir at a speed of 80r / min for 10min, then add copper chloride dihydrate into the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com