Hydraulic circuit for construction machinery

A construction machinery and hydraulic circuit technology, applied in the front-end application field, can solve the problems of reducing the replacement time and labor of working tools, and achieve the effect of improving workability, reducing time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

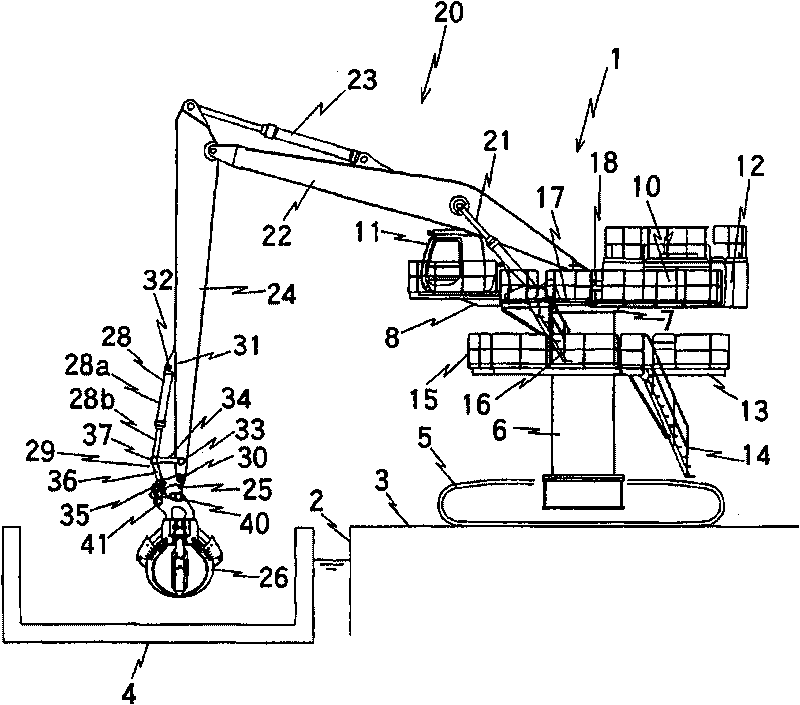

[0033] figure 1 It is a side view showing an example of the construction machine of the present invention. Reference numeral 1 denotes a construction machine that performs loading and unloading work on the ground 3 near the embankment 2 , and is a machine that loads and unloads cargo loaded on a ship 4 . Reference numeral 5 represents a self-propelled undercarriage. In this example, the case where the undercarriage 5 is a crawler-type undercarriage is shown. The condition of the vehicle.

[0034] A tower 6 is provided on the running body frame of the undercarriage 5 , and an upper revolving body 8 is provided on the top of the tower 6 via a revolving device 7 . A hydraulic power unit 10 , a cab 11 , a counterweight 12 and the like are mounted on the upper revolving structure 8 . In the midway of the tower 6 and under the lower surface of the upper revolving body 8 , a platform 13 for maintenance and inspection, such as a hydraulic power unit 10 mounted on the upper revolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com