Cable tunnel shaft enclosure structure and shield machine cutting construction method thereof

A technology of enclosure structure and cable tunnel, applied in tunnels, shaft equipment, earthwork drilling and other directions, can solve the problems of increasing the construction cost of shaft enclosure, prolonging the construction period, increasing the influence of surrounding traffic and buildings, etc. Safety, speeding up construction progress, reducing labor difficulty and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

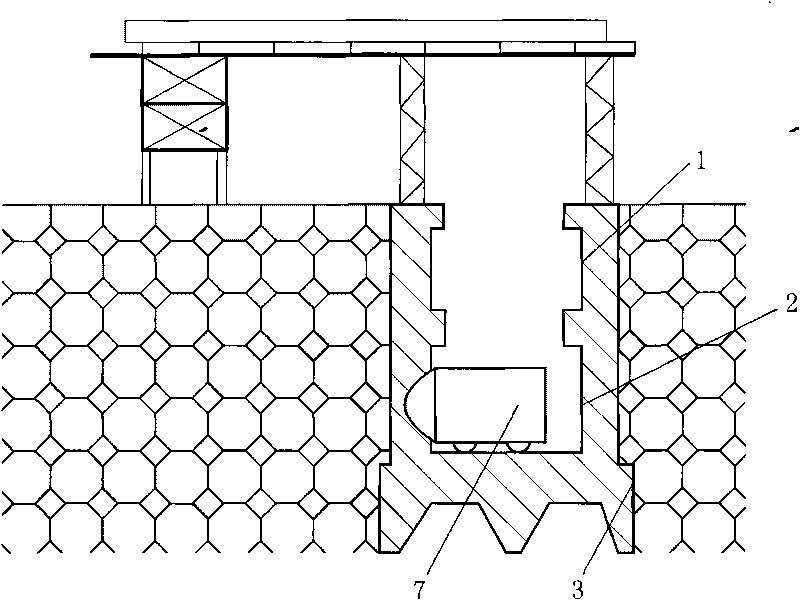

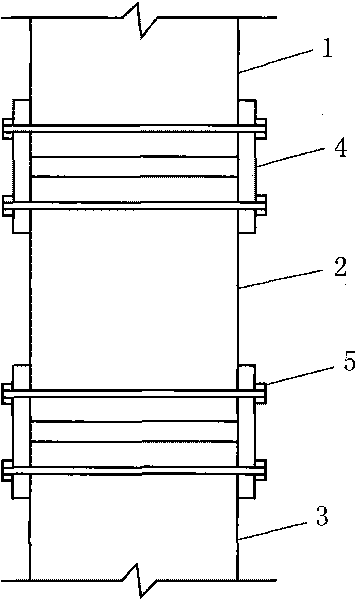

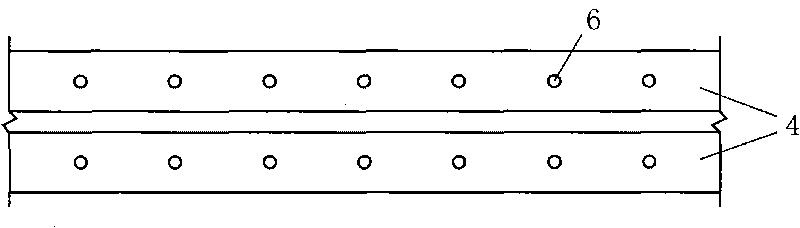

[0017] Please also refer to figure 1 , figure 2 and image 3 , the enclosure structure of the present invention is different from the traditional enclosure structure. The traditional enclosure structure usually uses steel bars or steel plates as reinforcements, while the reinforcement structure of the present invention is composed of upper and lower reinforcement cages and middle FRP reinforcement cages 2; The position of the FRP cage 2 corresponds to the position where the shield machine 7 enters and exits the shaft of the cable tunnel, and the height of the FRP cage 2 is greater than the height of the shield machine 7, so that the shield machine 7 can pass through the FRP cage 2 ; The upper reinforcement cage 1, the middle FRP reinforcement cage 2, and the lower reinforcement cage 3 are connected to form a complete reinforcement structure. Among them, the FRP reinforcement cage 2 can be a GFRP reinforcement cage or a CFRP reinforcement cage; the upper reinforcement cage 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com