Element tracing system and element tracking method thereof

A traceability system and component technology, applied in the field of traceability system, can solve problems such as inability to accurately query components, inability to repair products or trace production responsibilities, etc., to achieve the effect of ensuring the quality of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

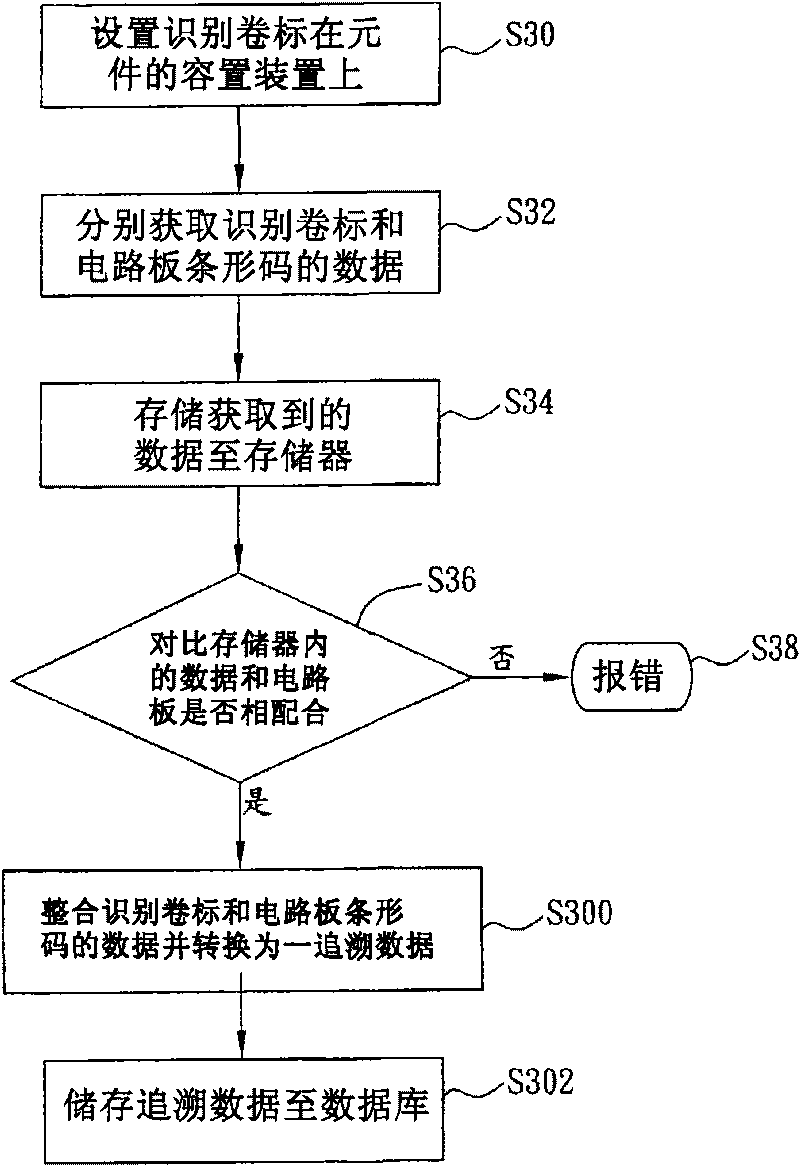

[0013] The component traceability system disclosed in this embodiment is a system applied to a surface mount technology (SMT) production line, and it can also be applied to other electronic assembly processes, such as semi-automatic insertion technology, dip soldering assembly process, automatic insertion The process of installing a large number of electronic components on the circuit board at the same time, such as assembly and wave soldering technology.

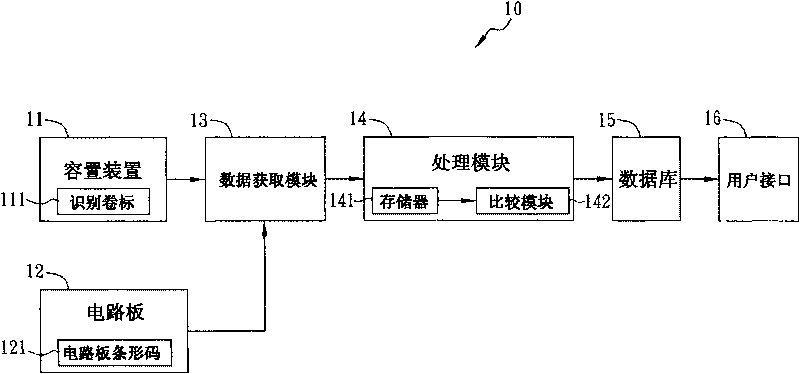

[0014] figure 1 Shown is a functional block diagram of a preferred embodiment of the present invention. Please refer to figure 1 , the component traceability system 10 includes a storage device 11 , a circuit board 12 , a data acquisition module 13 , a processing module 14 and a database 15 .

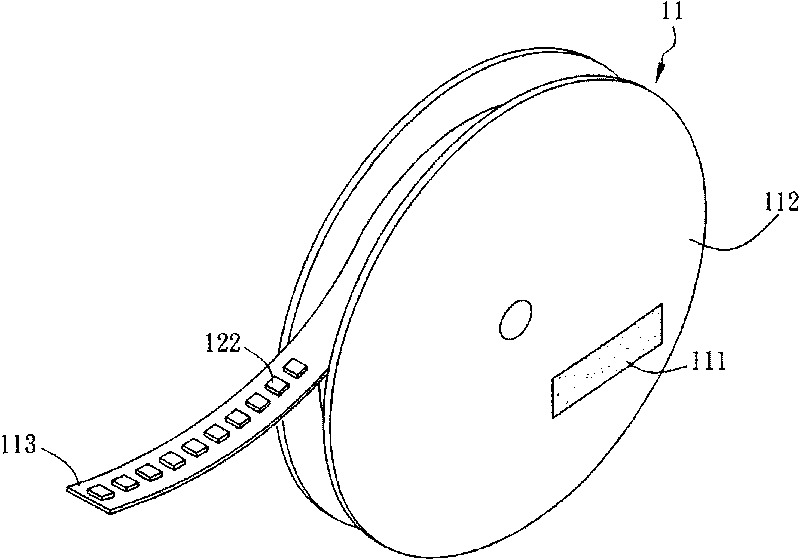

[0015] In the SMT process, multiple identical electronic components (such as resistors) may be mounted on one surface of the same circuit board. In this embodiment, the accommodating device 11 accommodates a plurality of electroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com