Array substrate of thin film transistor and liquid crystal display panel

A technology of liquid crystal display panels and thin film transistors, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of difficult repair lines, narrow spacing, and increased production costs, so as to eliminate line defects and reduce The effect of production cost and production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

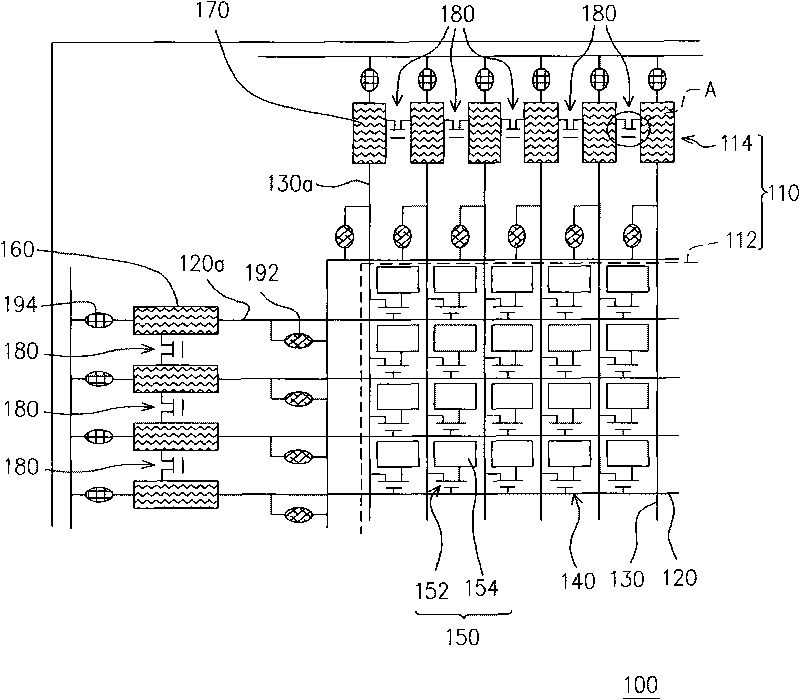

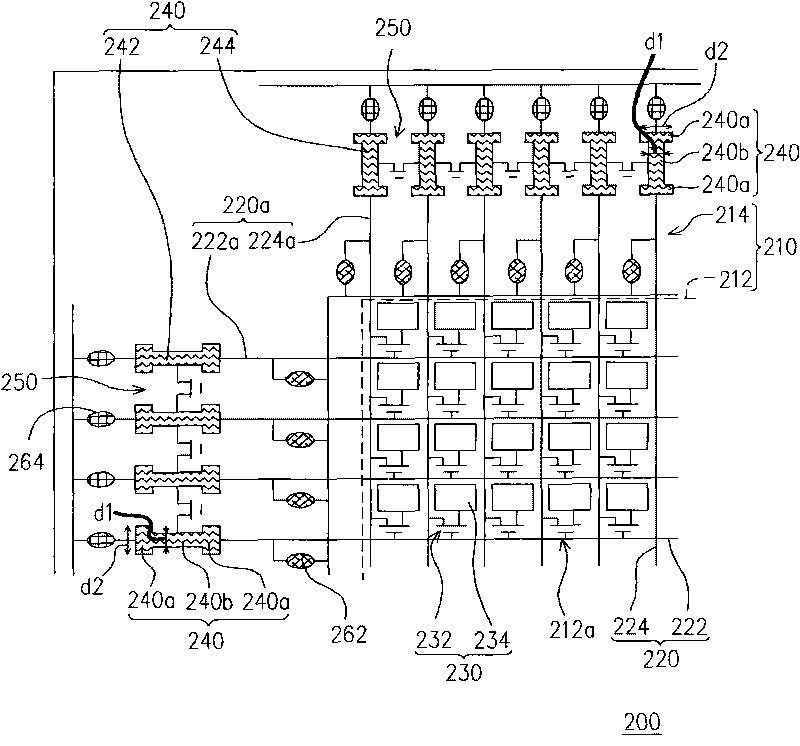

[0056] image 3 A schematic diagram of a thin film transistor array substrate according to a preferred embodiment of the present invention is shown. Please refer to image 3 , the TFT array substrate 200 includes a substrate 210 , a plurality of electrode wires 220 , a plurality of pixel units 230 , a plurality of welding pads 240 and a plurality of switch components 250 .

[0057] The substrate 210 has a display area 212 and a peripheral circuit area 214 . The electrode wiring 220 is disposed on the substrate 210, wherein the electrode wiring 220 divides the display area 212 into a plurality of pixel areas 212a. The electrode wires 220 may include a plurality of scan wires 222 and a plurality of data wires 224 , wherein the scan wires 222 and the data wires 224 are perpendicular to each other.

[0058] The pixel units 230 are respectively disposed in one of the pixel regions 212 a, and are driven by the electrode wiring 220 . Each pixel unit 230 may include: a thin film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com