Convection heat-radiation system for temperature control of electronic equipment close to space vehicle

It is a technology of electronic equipment and adjacent space, which is applied in the direction of electrical equipment construction parts, circuits, electrical components, etc. It can solve the problems of different equipment heat dissipation problems, different heat dissipation measures of stratospheric aircraft, etc., and achieve system reliability guarantee and structure Compactness, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Taking the realization of the temperature control requirement of electronic equipment at 35±5°C as an example, the specific implementation steps for realizing the present invention are as follows:

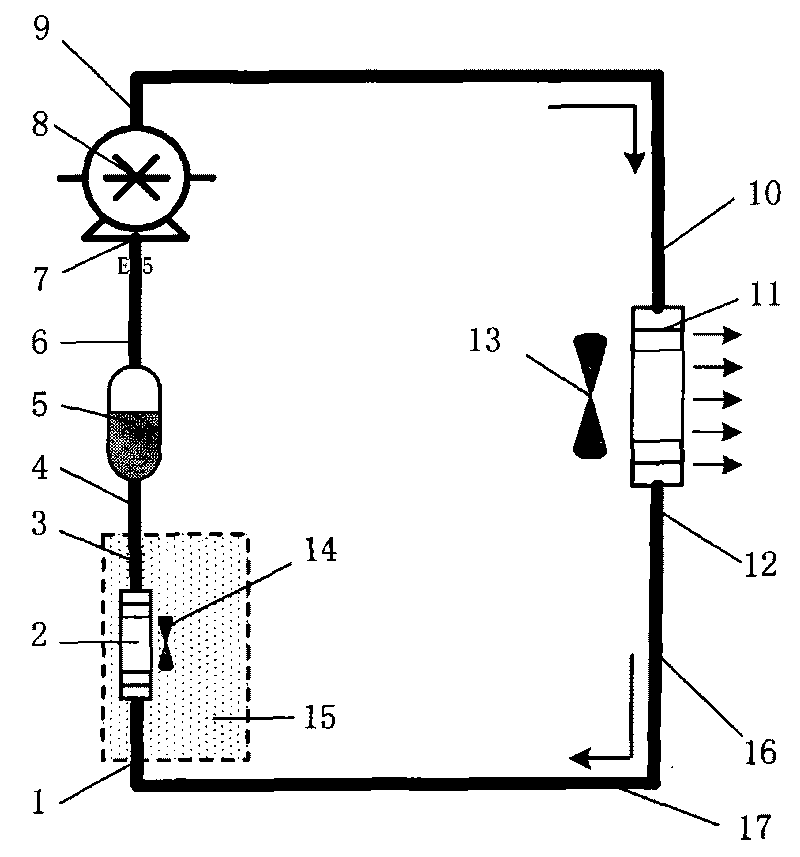

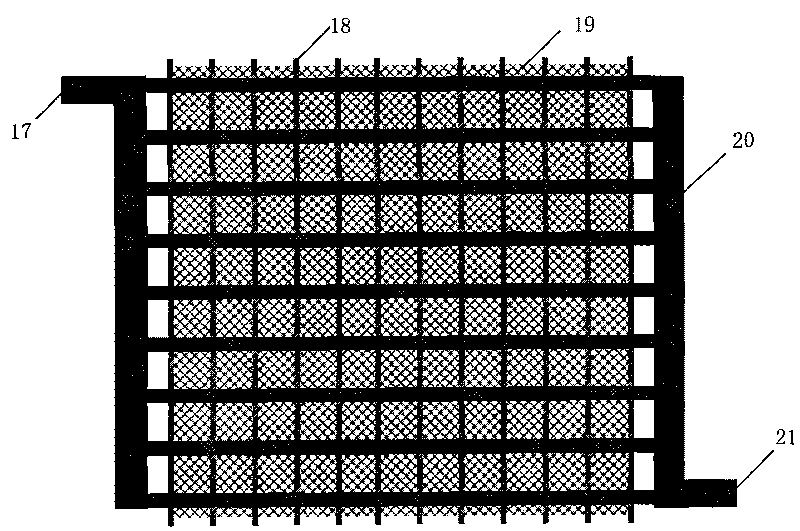

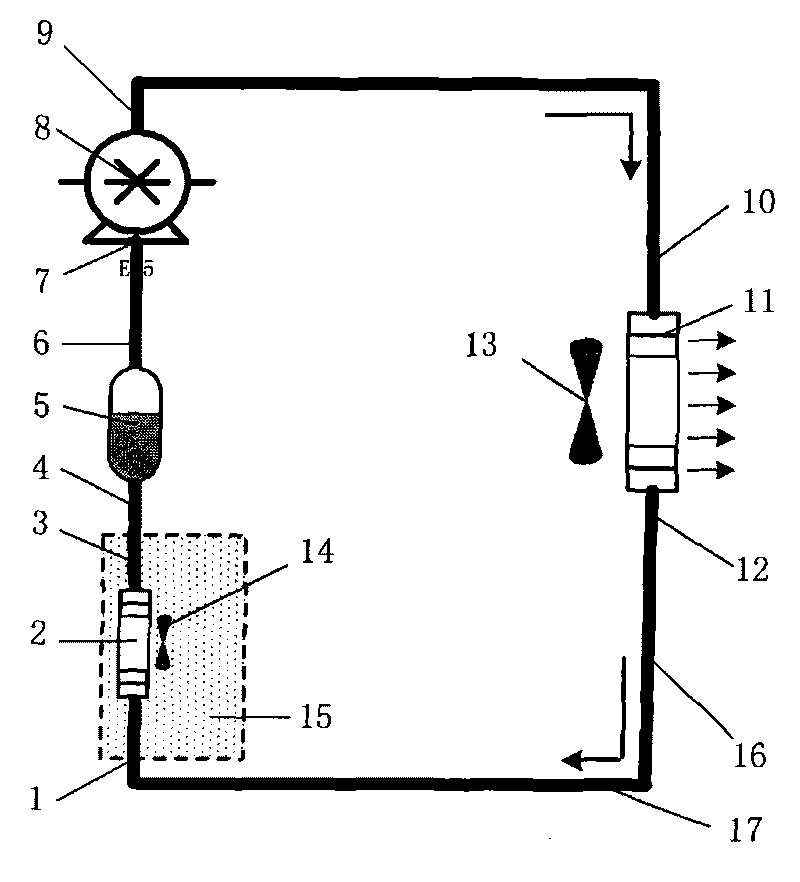

[0011] combine figure 1 , the electronic equipment cooling system of the present invention consists of an electronic equipment pressure holding cabin 15, a liquid storage tank 5, a pump 8, a tube-fin heat exchanger 2 in the cabin, a fan 14 for the radiator in the cabin, and a tube-fin heat exchanger 11 outside the cabin. , the outboard radiator is made up of blower fan 13, pipeline 16, and circulating fluid working medium 17.

[0012] 1. Design the fluid pump circuit to transfer the waste heat in the electronic equipment compartment to the external radiator, such as figure 1 As shown, the single-phase fluid circuit fluid working medium 17 is ethylene glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com