Method for producing wear-resistant composite roller

A manufacturing method and technology of composite rolls, which are applied in the field of roll manufacturing, can solve problems such as low strength of the roll core, easy occurrence of slag inclusions in the joint layer of the roll core and the roll body, and roll peeling, so as to achieve good wear resistance of the roll and improve the joint layer quality, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

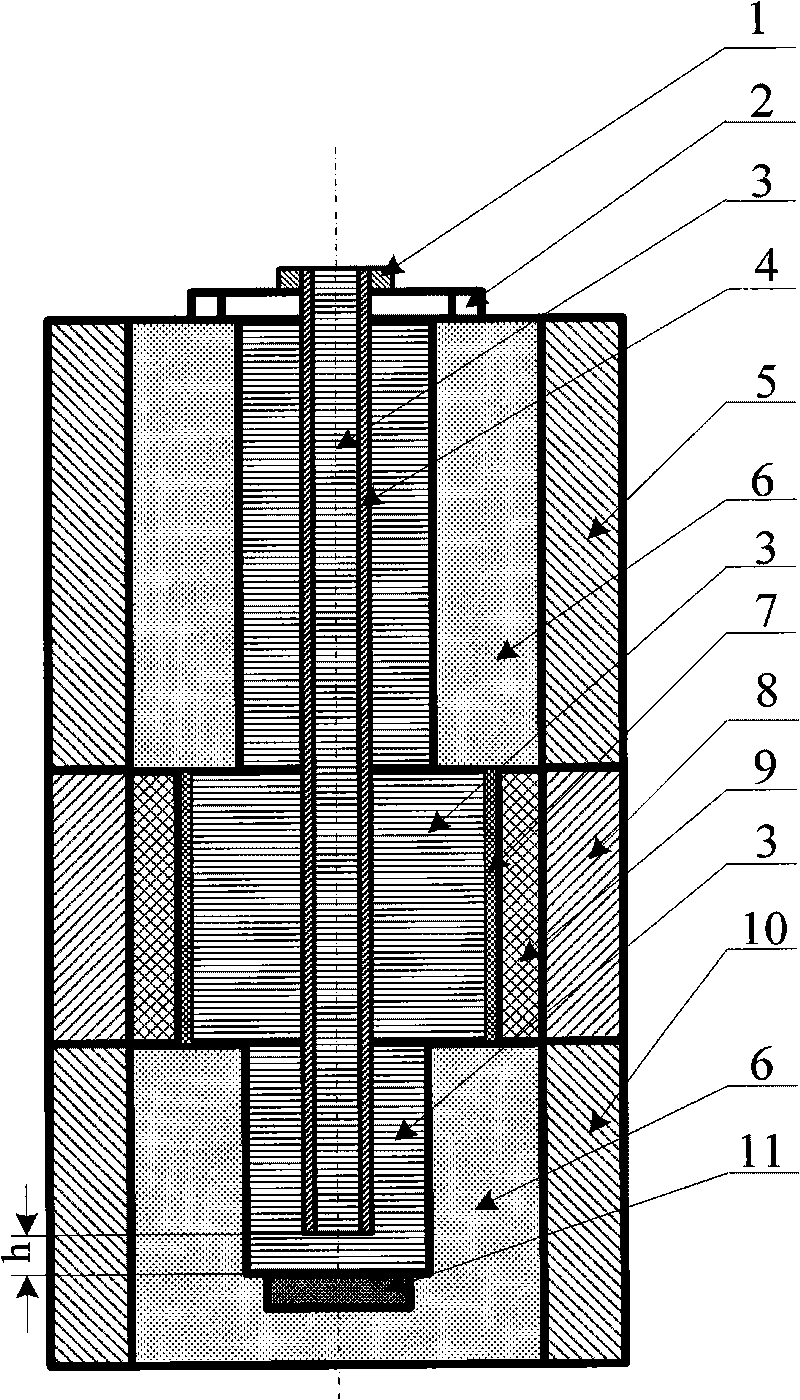

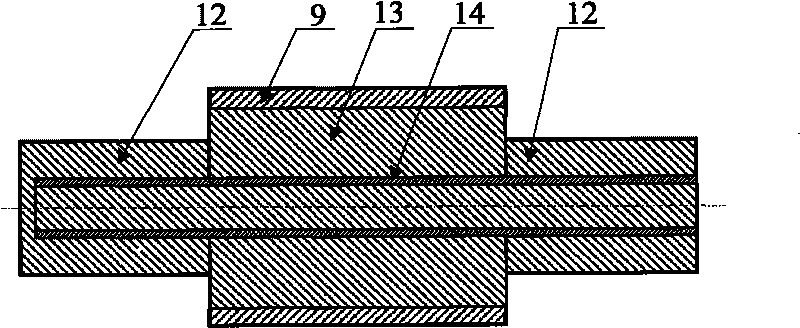

[0024] The centrifugal casting method is used to cast φ650mm×1700mm high-speed steel composite roll, the outer layer of the roll is high-speed steel, and the roll center and roll neck are ductile iron. First, the high-speed steel and the ductile iron are smelted separately in an electric furnace. Then pour the wear-resistant outer layer high-speed steel metal liquid of the composite roll into the cold type (8) installed on the horizontal centrifuge. After the roll outer layer high-speed steel metal liquid has been poured, add 300 ℃ baked steel into the cold type Glass slag (7), the composition (mass fraction) of glass slag is 42.5% SiO 2 , 41.8% Na 2 O, 9.5% B 2 o 3 and 6.2% Al 2 o 3 , the amount added is controlled at 2.0kg / m 2 (the inner surface of the wear-resistant outer layer of the roll), which evenly covers the inner surface of the outer layer of the roll under the action of centrifugal force. After the outer layer of high-speed steel liquid is solidified, the ce...

Embodiment 2

[0026] The centrifugal casting method is used to cast φ730mm×2600mm high-nickel-chromium cast iron composite roll. The outer layer of the roll is high-nickel-chromium cast iron, and the roll center and roll neck are nodular cast iron. First use electric furnace to smelt high-nickel-chromium cast iron and nodular cast iron respectively. Then pour the wear-resistant outer layer high-nickel-chromium cast iron metal liquid of the composite roll into the cold mold (8) installed on the horizontal centrifuge. The glass slag (7) baked at ℃, the composition (mass fraction) of the glass slag is 51.3% SiO 2 , 33.1% Na 2 O, 7.6% B 2 o 3 and 8.00% Al 2 o 3 , the amount added is controlled at 2.5kg / m 2 (the inner surface of the wear-resistant outer layer of the roll), which evenly covers the inner surface of the outer layer of the roll under the action of centrifugal force. After the outer layer of high-nickel-chromium cast iron liquid is solidified, the centrifugal cold form is hois...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com