Process for machining L-shaped ferrule of rotary bearing

A technology of slewing bearings and processing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of ring size change, large turning amount, stress distribution change, etc., to prevent stress redistribution and eliminate grinding stress , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Firstly, select a medium-carbon steel forging blank made of 50Mn or 42CrMo, and perform normalizing treatment before cutting: heat the forging blank to 30-50°C above Ac3, keep it warm for 3 hours, and then cool it in the air.

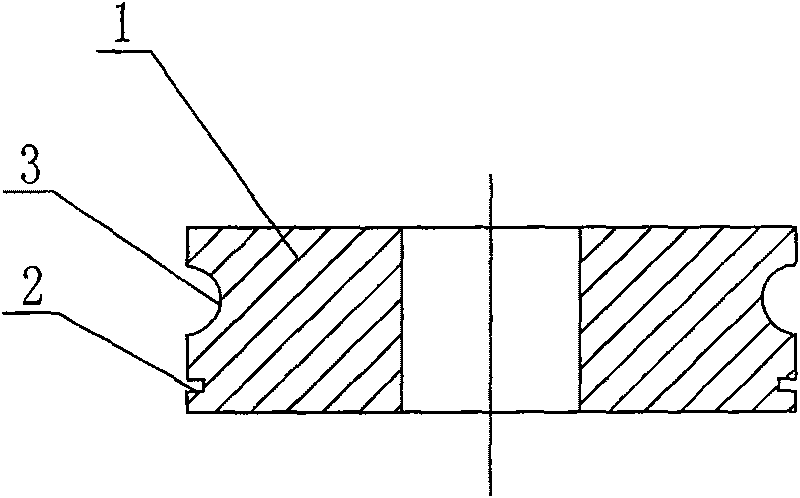

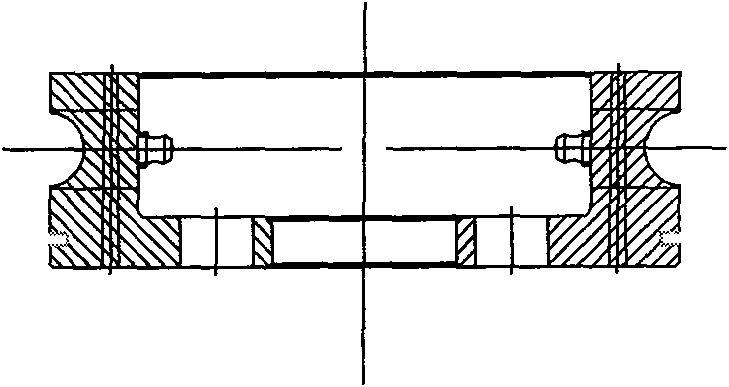

[0011] Then roughing: as in figure 1 As shown, it is processed into a circular blank on the CA5116E ordinary vertical lathe, and the inner hole is opened in the center to make the ring 1, and the sealing groove 2 and the raceway 3 are processed on the SVT160X10 / 80 CNC vertical lathe. After the rough machining is completed, the ellipse of the inner hole of the ring is measured within 0.15mm.

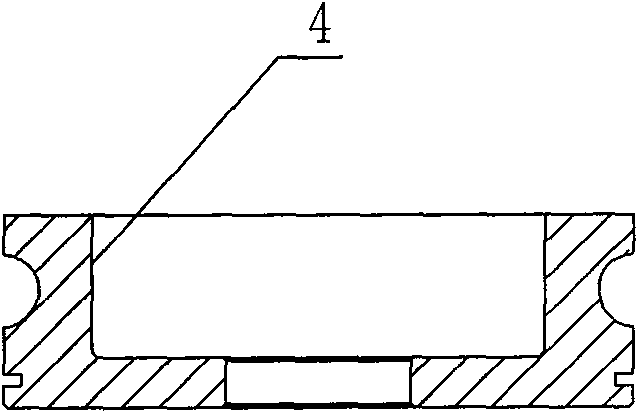

[0012] Raceway quenching and tempering treatment: quench the raceway 3 on the ring 1, and its structure changes from supercooled austenite to martensite, then heat it to 195-200°C, keep it warm for 5 hours, and then cool it to room temperature to increase its toughness. The hardness of the raceway reaches HRC55-62, and the ellipse of the inner hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com