Energy-saving gas full-convection heating glass tempering furnace

A glass tempering and energy-saving technology, applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problem of low energy utilization rate, avoid energy loss, facilitate maintenance, and improve energy utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The best solution for implementing the present invention will be described below in conjunction with the accompanying drawings.

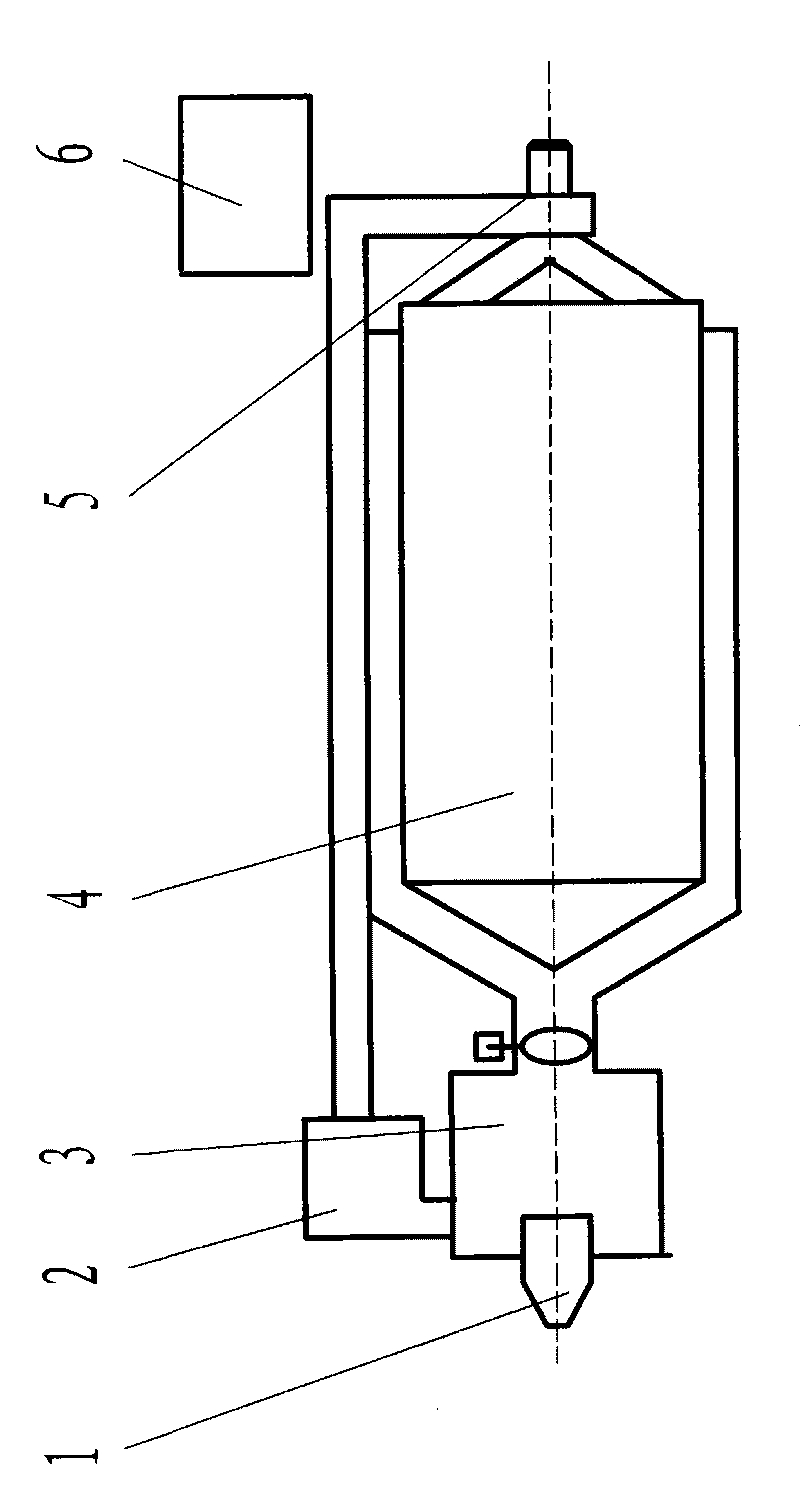

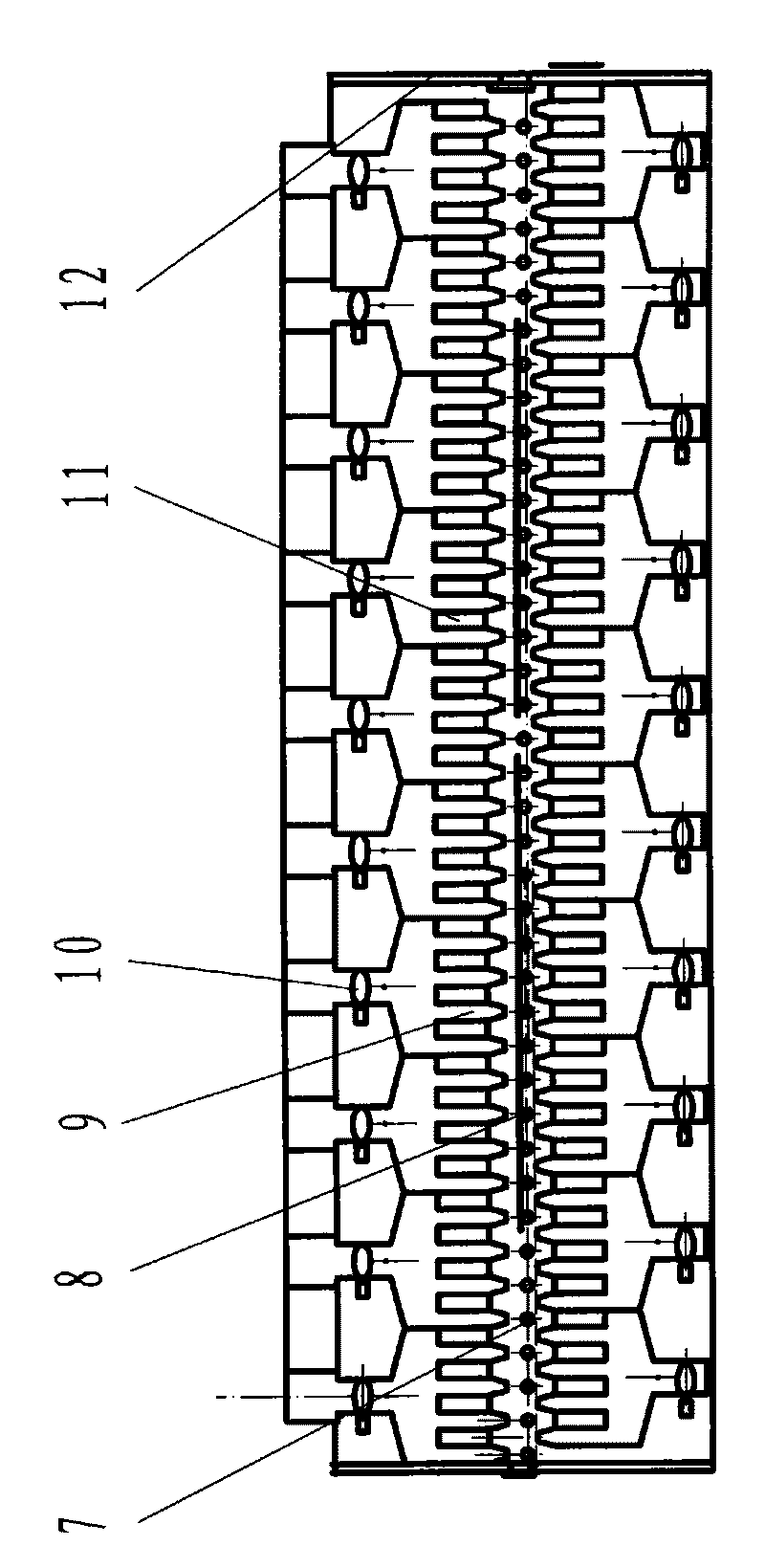

[0020] Accompanying drawing 1 shows that the energy-saving gas-fired full convection heating glass tempering furnace of the present invention consists of a combustion chamber (1), a hot gas temperature and pressure regulating chamber (3), a high temperature forced convection heating chamber (4), and a hot gas recovery fan system (5) , waste heat recovery and utilization system (2) and measurement and program control system (6). Accompanying drawing 2 shows the glass delivery system (7), heated glass (8), high-temperature airflow jet heating system (9), hot airflow adjustment system (10), waste heat gas recovery box (11) in the high-temperature forced convection heating chamber And the structural layout of body of heater (12).

[0021] The combustion chamber (1) is a device that uses natural gas or indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com