Method for extracting capsaicine from yellow capsicum by using supercritical CO2 fluid

A supercritical, yellow cherry pepper technology, applied in the production of bulk chemicals, organic chemistry, separation/purification of carboxylic acid amides, etc., to achieve the effect of high Vc content, stable product quality, and avoiding product oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

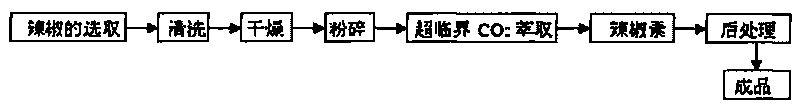

[0053] A supercritical CO 2 The method for fluid extracting capsaicin from yellow cherry peppers comprises the following technical steps:

[0054] 1. Selection of peppers;

[0055] 2. Cleaning;

[0056] 3. Drying;

[0057] 4. Crushing;

[0058] 5. Supercritical CO 2 Fluid extraction of capsaicin;

[0059] 6. Post-processing;

[0060] 7. Finished product.

[0061] The raw material of this example, yellow cherry pepper, is taken from the self-built base of Zhejiang Zhongwei Brewing Co., Ltd. Yellow cherry pepper is the result of the company's "breeding and development of processed high-spicy pepper varieties" project. Yellow cherry pepper has the advantages of high spiciness and large output, which is very suitable for industrial processing and production. After the implementation of the project, the company's annual output of yellow cherry peppers can reach more than 30,000 tons, ensuring the stability of raw material supply and product quality in the production process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com