In-situ polymerization technology for preparing anti-settling luminous acrylic resin

An in-situ polymerization and acrylic acid technology, which is applied to the treatment of luminescent materials, luminescent coatings, and dyed organosilicon compounds, can solve problems such as poor storage stability, easy sedimentation, and unstable luminous coatings, and achieve uniform luminous brightness. Simple, outstanding anti-sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

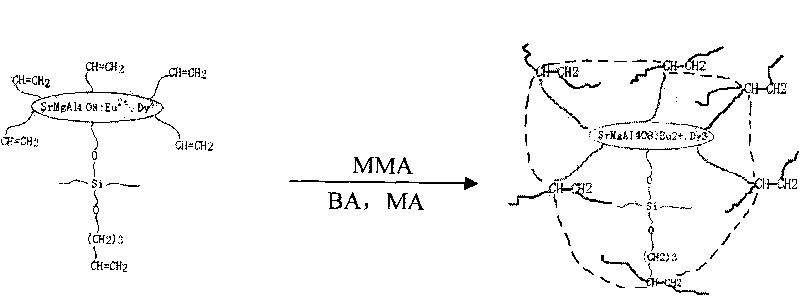

[0032] Embodiment 1: the surface-modified luminous powder can be obtained according to the following method:

[0033] ① Add 6 parts of 400-mesh luminous powder to 58 parts of absolute ethanol in parts by weight, disperse by ultrasonic wave for 20 minutes, add 2 parts of γ-(methacryloyloxy)propyltrimethoxysilane, stir evenly, and add concentration 1 mol / L dilute H 2 SO 4 When the pH is 1, transfer to a constant temperature heating magnetic stirrer, react at 70°C for 4 hours, filter with suction, and dry at 80°C for 1 hour to obtain modified luminous powder.

[0034] ② Add 7.5 parts of 400 mesh luminous powder to 73 parts of absolute ethanol in parts by weight, ultrasonically disperse for 20 minutes, add 2.5 parts of γ-(methacryloyloxy)propyltrimethoxysilane, stir evenly, and add concentration 1 mol / L dilute H 2 SO 4 When the pH is 1, transfer to a constant temperature heating magnetic stirrer, react at 70°C for 4 hours, filter with suction, and dry at 80°C for 1 hour to obt...

Embodiment 2

[0036] Example 2: Take a certain proportion of acrylic acid monomer (15 parts of MMA, 10 parts of BA, 5 parts of MA), an appropriate amount of initiator BOP, and 30 parts of xylene, and react in a constant temperature heating stirrer at 80°C. First polymerize for 20 minutes to form a prepolymer; then add 1 part of modified luminous powder, continue the polymerization until the solid content of the resin is about 50%, and then discharge. All the other are with embodiment 1.

Embodiment 3

[0037] Example 3: Take a certain proportion of acrylic acid monomer (17.5 parts of MMA, 17.5 parts of BA, 5 parts of MA), an appropriate amount of initiator BOP, and 30 parts of xylene, and react in a constant temperature heating stirrer at 80°C. First polymerize for 20 minutes to form a prepolymer; then add 1 part of modified luminous powder, continue the polymerization until the solid content of the resin is about 50%, and then discharge. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com