Construction method for vibrator pipe sinking high-pressure grouting underpinning pile extracting

A technology of high-pressure grouting and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of hidden dangers left by construction, high cost, and large vibration and noise, and achieve improved bearing capacity, high work efficiency, and The effect of low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

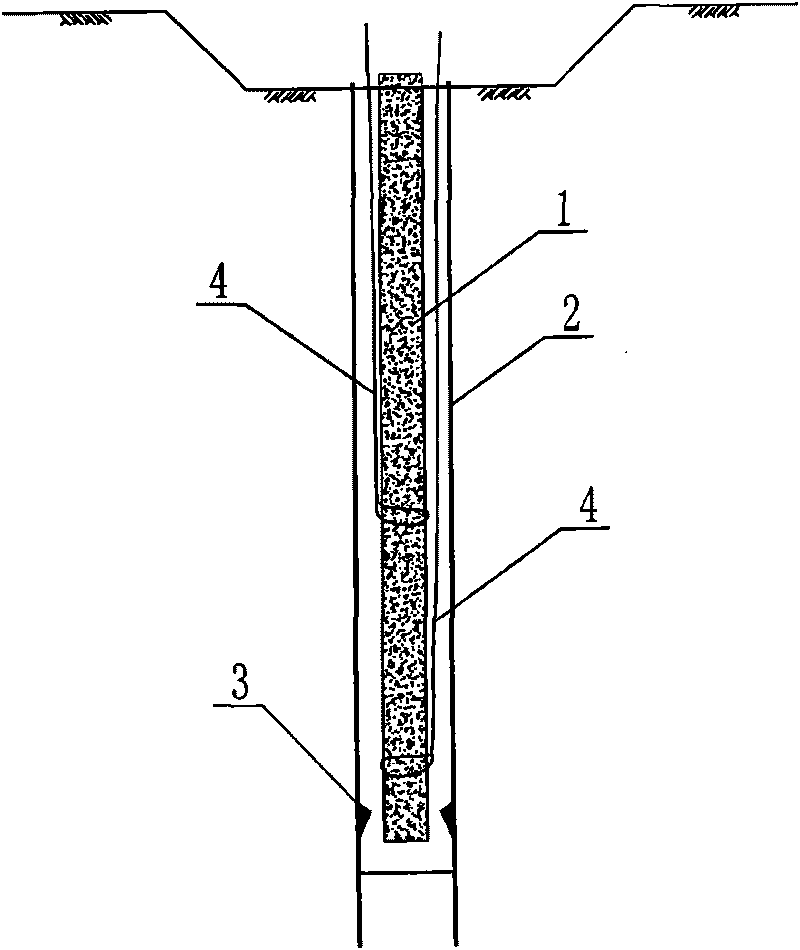

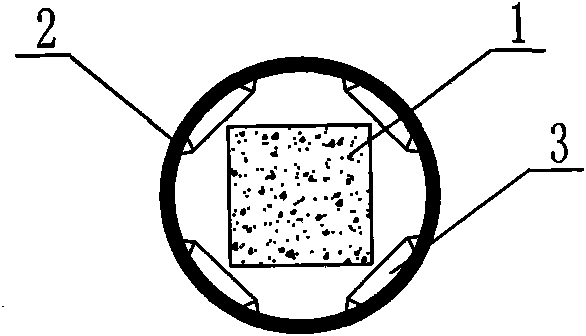

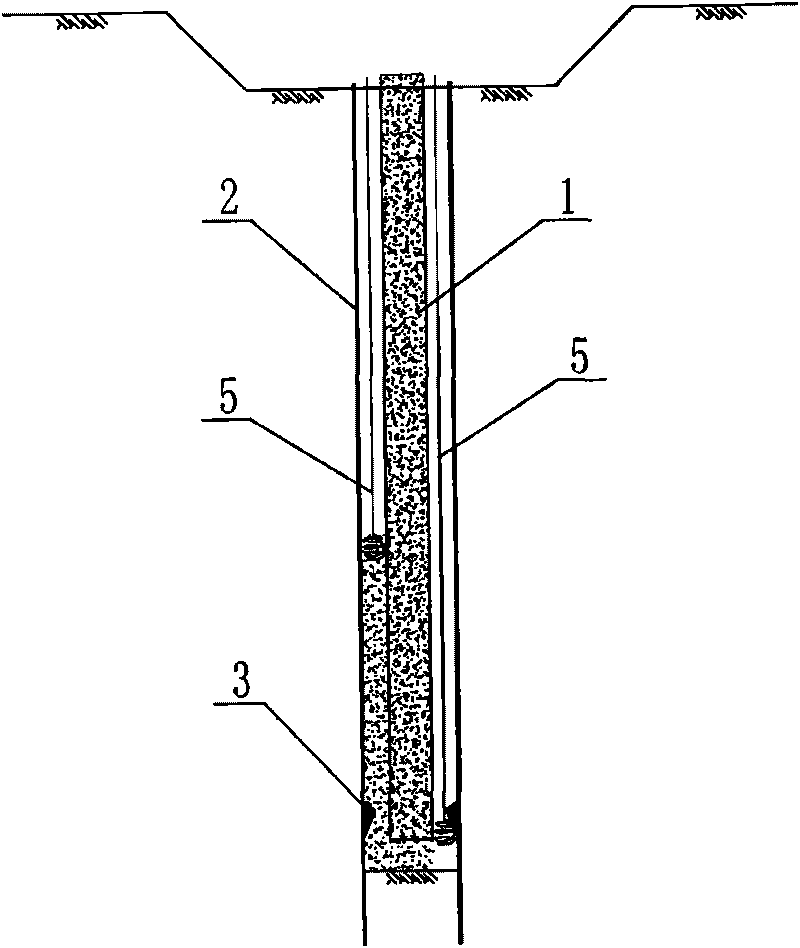

[0019] See attached figure 1 , attached figure 2 , The construction steps of the present invention include: vibrating the steel casing, grouting to strip the soil around the pile body, pulling out the pile and grouting underpinning. Excavate the pile top structure of the pile 1 to be pulled out and the soil around the pile 1 to expose the pile head, and sink the steel casing 2 to the design elevation of the pile 1 by using the vibration sinking method. Locator 3, the locator 3 is four pieces evenly arranged in the lower end of the steel casing 2 and fixed to the inner wall of the steel casing 2, the locator 3 is mainly to ensure the distance between the steel casing 2 and the pile 1, so as to facilitate the drill pipe 5 Drill down and lower the wire rope hoisting ring 4. Then the high-pressure rotary jetting drill pipe 5 is drilled down to the design elevation of the pile 1 along the inner wall of the steel casing 2 and the side wall of the pile 1. When the drill pipe 5 ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com