Improved miniature hot air engine

A heat engine, small-scale technology, applied in the direction of heat variable engine devices, mechanical equipment, machines/engines, etc., can solve the problems of high heat source requirements, high manufacturing costs, complex structure of heat engines, etc., and achieve flexible and simplified positions Structure, the effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

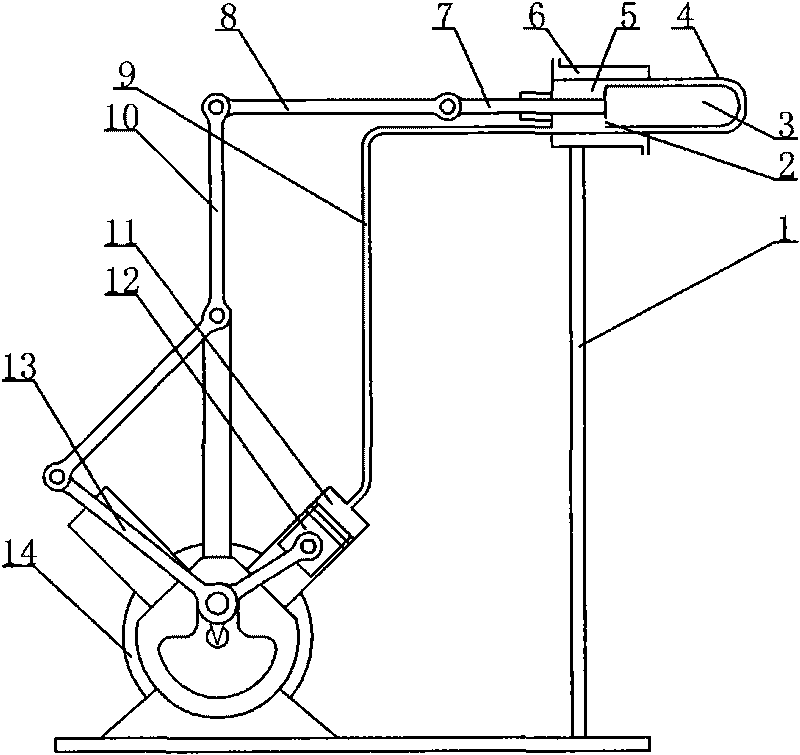

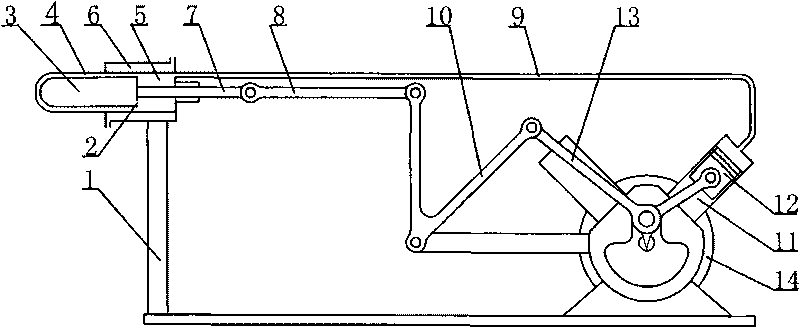

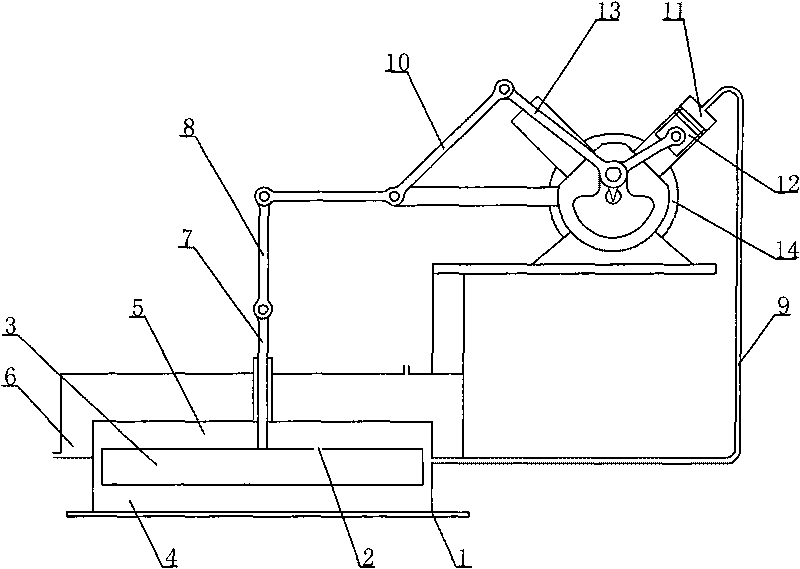

[0010] An improved small heat engine such as figure 1 As shown, including the heater 4 and the power cylinder 11 arranged on the crankcase 14, the power piston 12 in the power cylinder 11 is connected to the crankshaft in the crankcase through the connecting rod and the gas distribution piston 3 is installed in the gas distribution cylinder 5 , the air distribution cylinder 5 connected with the heater 4 is horizontally arranged on the support 1, and the cooler 6 is arranged on the air distribution cylinder 5. Cooling jacket for water inlet and outlet. Or the cooler 6 is provided with air-cooled cooling fins evenly distributed on the outer wall of the air distribution cylinder 5 . In the air distribution cylinder 5, a cylindrical air distribution piston 3 with a metal shell having a vent hole 2 on the outer end surface is installed with a clearance fit, and the matching clearance between the air distribution piston 3 and the air distribution cylinder 5 is 2-15% of the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com