Self-control fluid jet and drainage lift pump

A technology of fluid injection and lifting pumps, which is applied in the direction of injection pumps, pumps, pump control, etc., which can solve the problems of high maintenance and operation costs, long exhaust time, easy corrosion and leakage of bottom valves, etc., so as to save investment, land occupation, and save Electricity and manpower, energy-saving effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

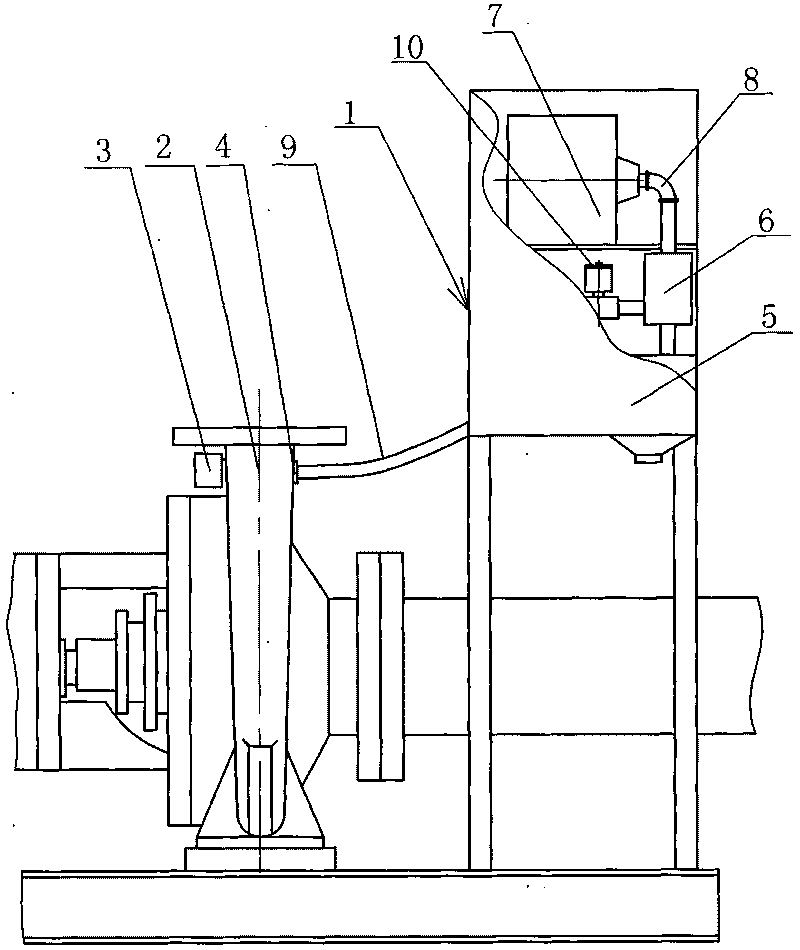

[0031] See figure 1 , the self-controlled fluid jet drainage lifting pump, including the fluid jet drainage device 1, the delivery pump 2 and the liquid level sensor 3 arranged on the delivery pump 2. The upper part of the delivery pump 2 is provided with an exhaust hole 4 that communicates with the inner cavity of the delivery pump 2. The fluid jet drainage device 1 is mainly composed of a housing 5 , a fluid vacuum ejector 6 and a fluid booster 7 arranged in the housing 5 . The fluid booster 7 is communicated with the fluid vacuum ejector 6 through the connecting pipe 8 , and the power fluid of the fluid vacuum ejector 6 comes from the fluid booster 7 built in the fluid ejection and drainage device 1 . A vacuum suction pipe 9 is drawn out from the fluid vacuum ejector 6 , and a vacuum solenoid valve 10 is installed on the vacuum suction pipe 9 .

Embodiment 2

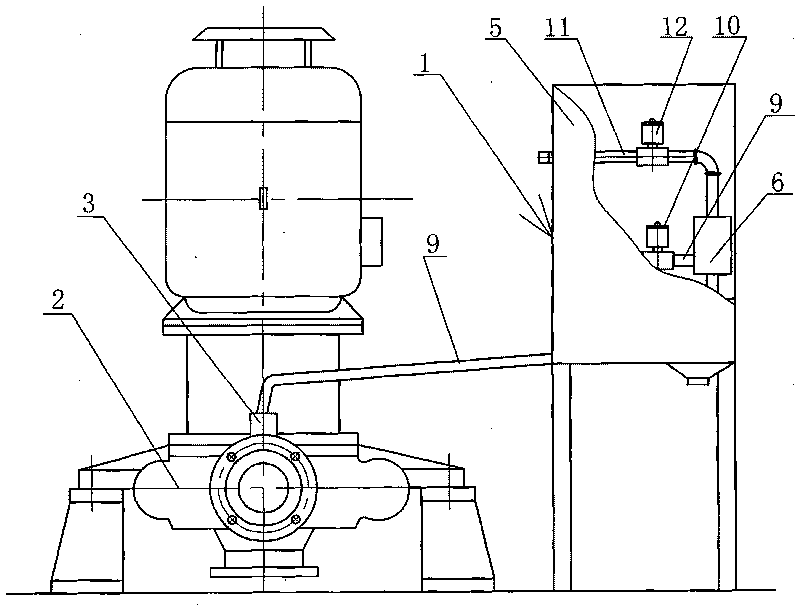

[0033] See figure 2 , the second embodiment is basically the same as the first embodiment, the difference is that the delivery pump 2 is a single-suction horizontal type, the fluid jet drainage device 1 is an external power type, the pressure fluid comes from the outside of the equipment, and the fluid vacuum ejector 6 is directly connected to an external The pressure fluid input pipe 11 is connected to each other, and an external pressure fluid valve 12 is installed on an external pressure fluid input pipe 11 .

Embodiment 3

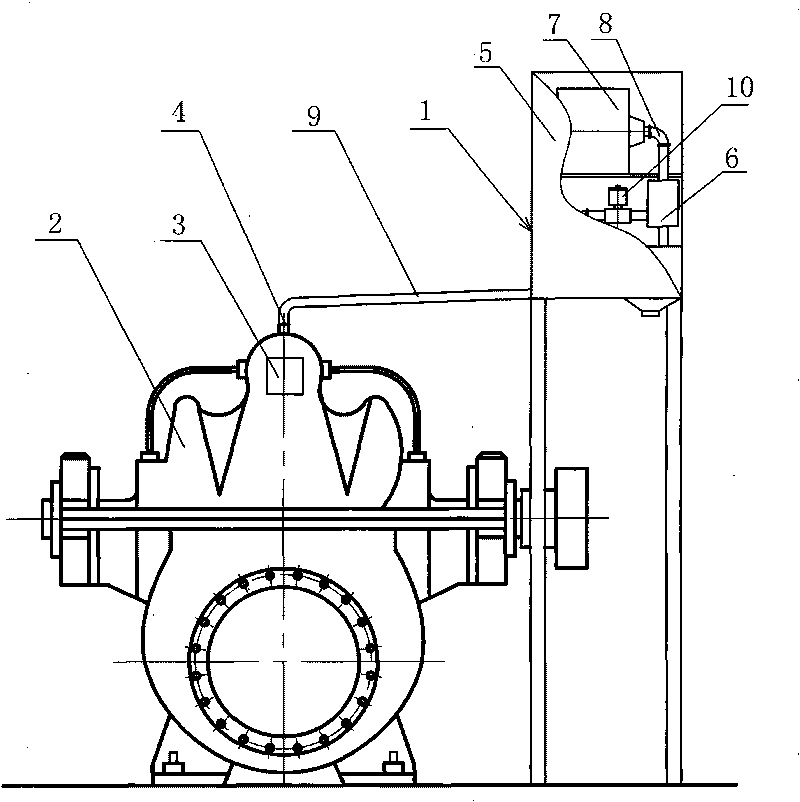

[0035] See image 3 , the third embodiment is basically the same as the first embodiment, the difference is that the delivery pump 2 is a double-suction horizontal type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com