On-site CVT integrated verification system

A test platform and test power supply technology, which is applied in the direction of measuring devices, instruments, and measuring electrical variables, can solve problems such as large constraints, affecting measurement results, and damage to test equipment, so as to reduce the uncertainty of additional errors and reduce manufacturing costs. , the effect of reducing the vertical height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The on-site CVT integrated verification system of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

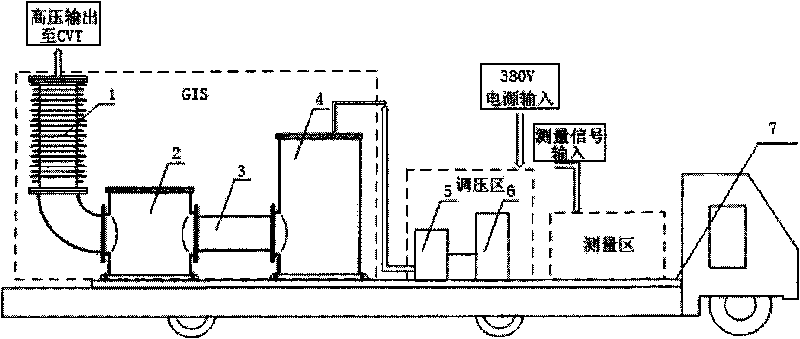

[0016] figure 1 Marks in: 1-high voltage bushing, 2-standard voltage transformer, 3-standard capacitor, 4-series reactor, 5-excitation transformer, 6-voltage regulator, 7-vehicle-mounted test platform.

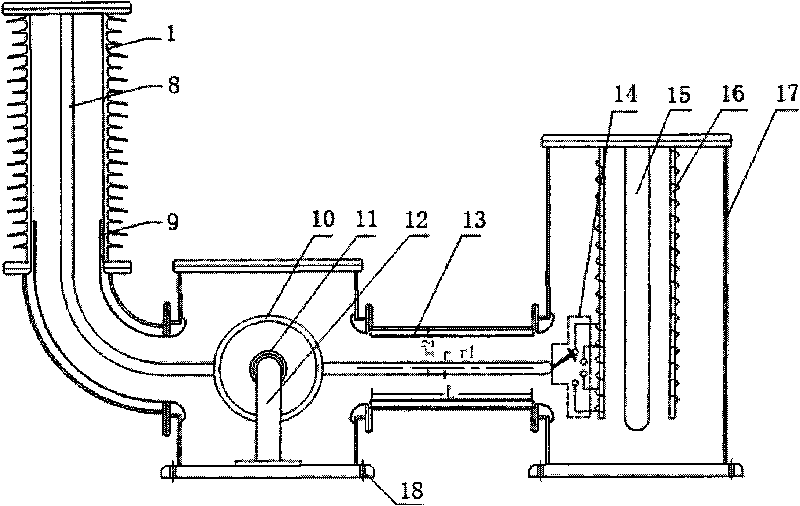

[0017] image 3 Marks in: 8-high voltage conductor, 9-ground potential shielding electrode, 10-transformer primary winding, 11-transformer secondary winding, 12-transformer core, 13-standard capacitor low-voltage electrode, 14-inductance switch Switch, 15-reactor core, 16-reactor inductance coil, 17-box body, 18-positioning connection hole, r1-high voltage conductor radius, r2-inner radius.

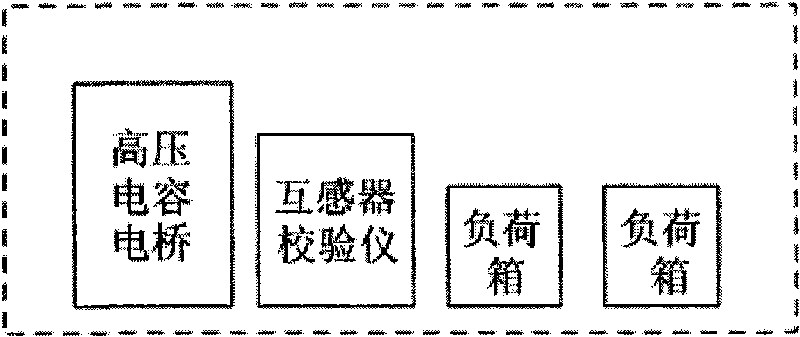

[0018] Marks in Figure 4: C1, C2-dividing capacitance of CVT under test, Lk-compensation reactor in CVT, Y1, Y2-load box, QS-high voltage capacitor bridge, HE-transformer calibrator.

[0019] The schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com