Method for detecting out-of-specification quality of product and estimating actually measured value of product

A technology of actual measurement and product quality, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as undetectable, detected, and quality exceeding specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

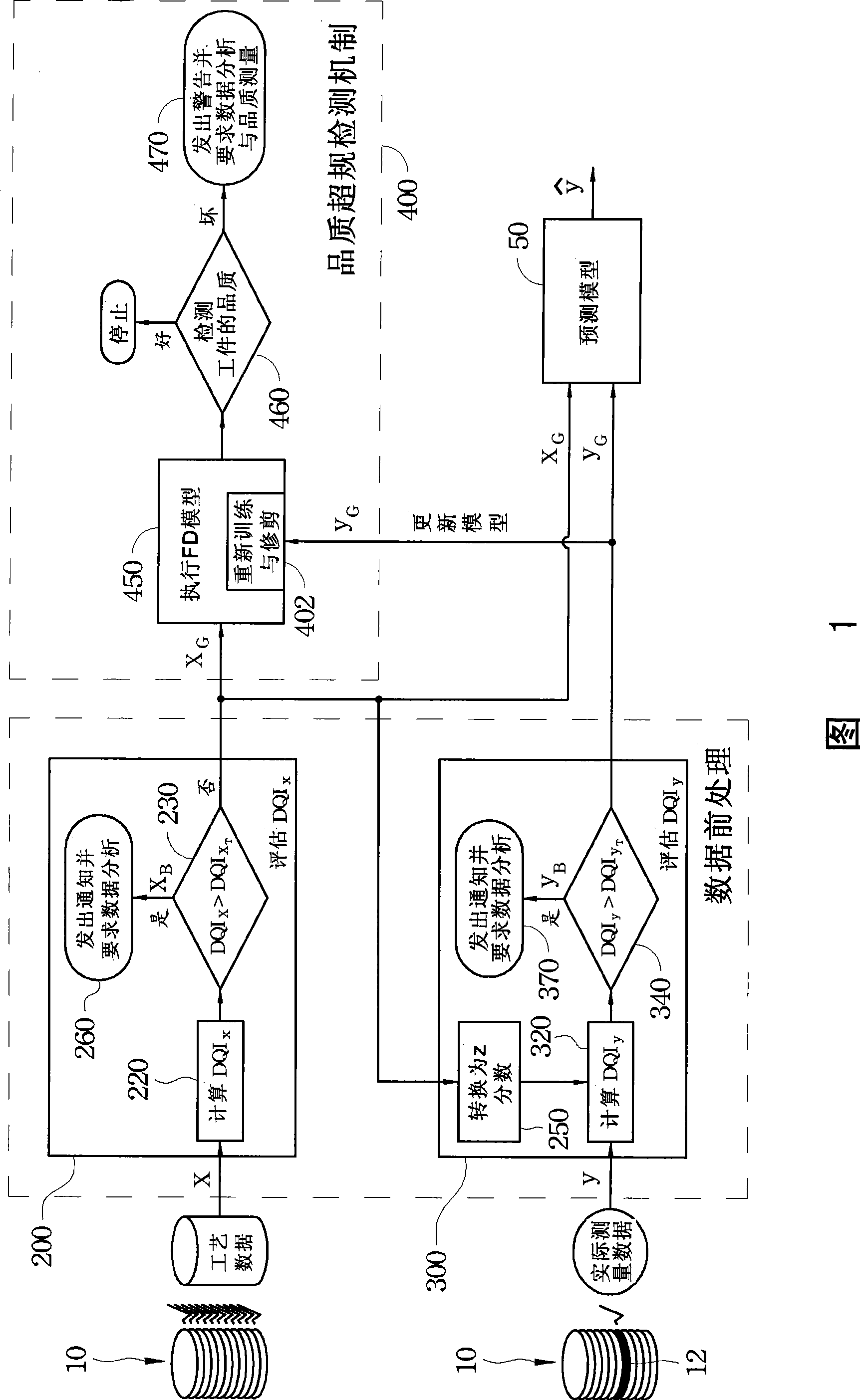

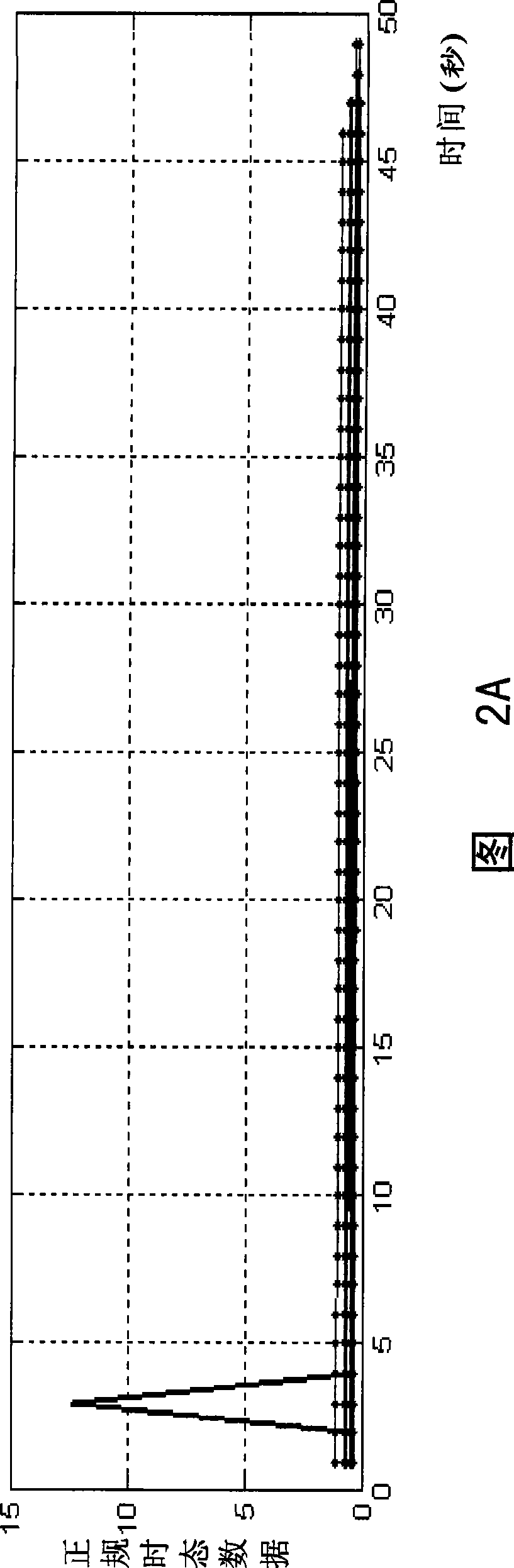

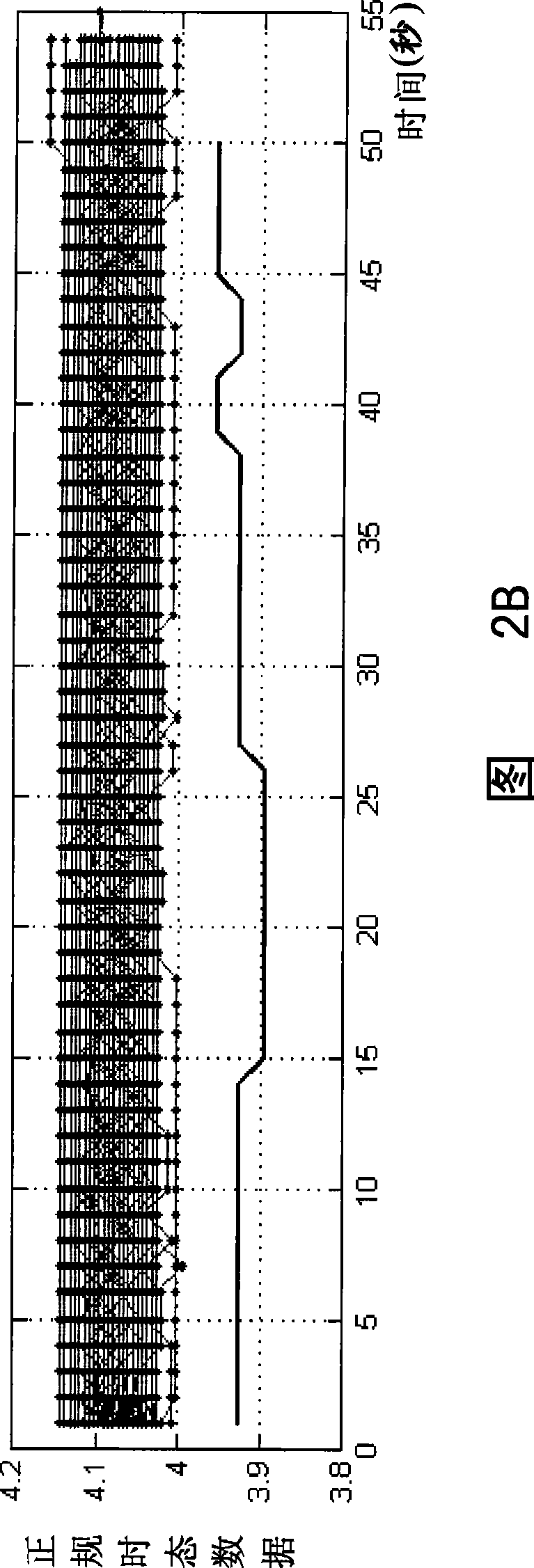

[0024] The present invention is mainly to provide quality indicator (DQI) of process data X )Model and measurement data quality indicator (DQI y ) Model and product quality inspection (FD) model, where DQI X The model is used to calculate the process data quality indicator value (DQI X Value); DQI y The model is used to calculate the measurement data quality indicator value of the actual measurement value of a certain workpiece; the FD model is used to detect whether the product is invalid or not in real time on the production line through the normal process data collected during the production process. defective. The present invention establishes DQI based on principal component analysis (PCA) and Euclidean distance (ED) X Model, and use the leave-one-out principle in interactive verification to determine the process data quality threshold Establish DQI according to Adaptive Resonance Theory 2 (ART2) and Normalized Variability (NV) y Model and apply the concept of the maximum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com