PLC-based two-dimensional motion demonstration platform for teaching and implementation method thereof

A two-dimensional motion and platform technology, which is applied to the teaching experiment platform and its realization field, can solve the problems of no teaching, interpolation operation, etc., and achieve the effects of convenient function expansion, strong anti-interference ability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

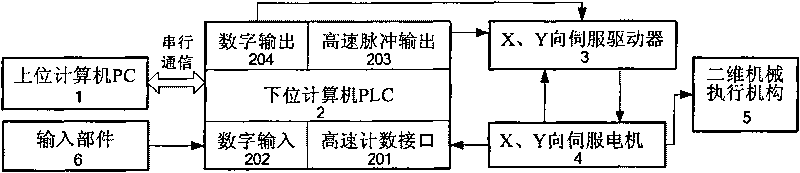

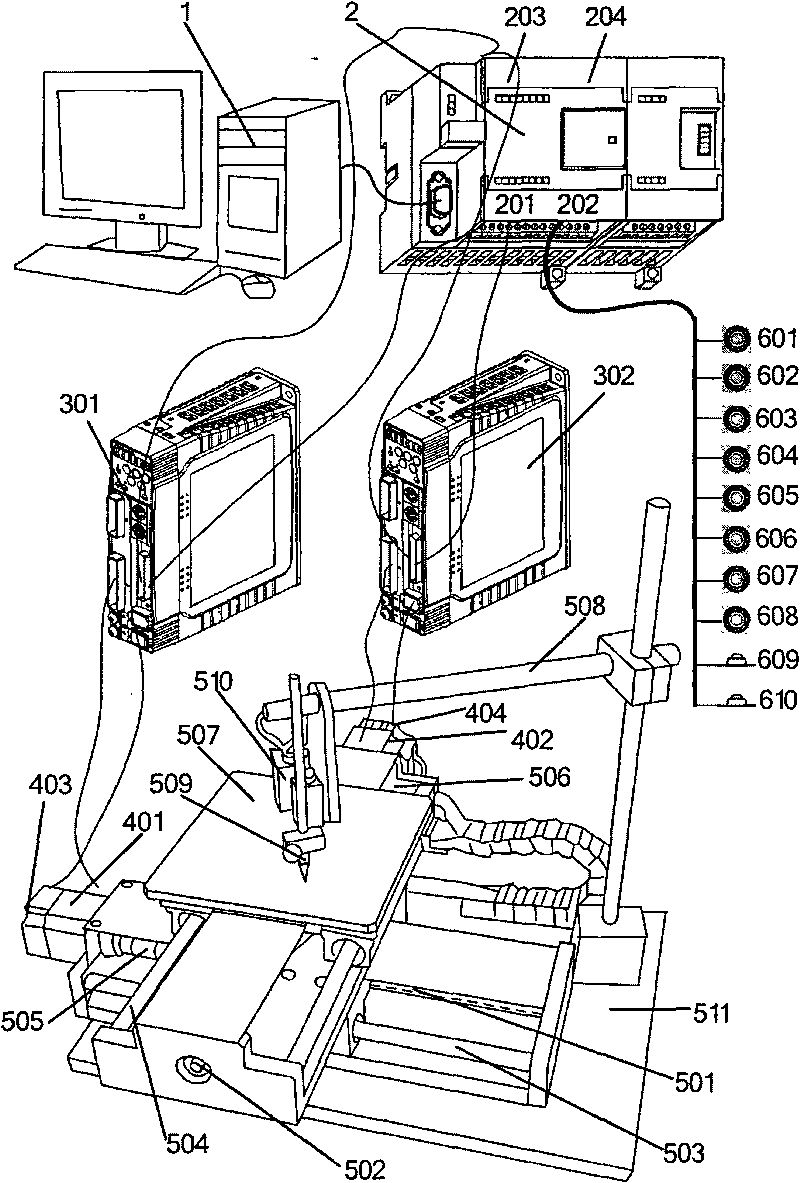

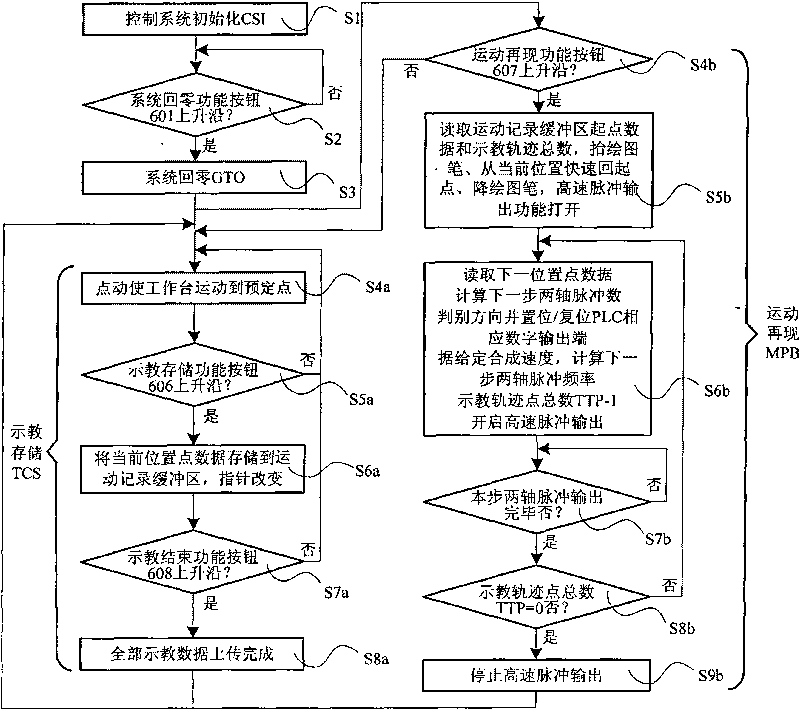

[0040] A PLC-based two-dimensional motion teaching platform for teaching, such as figure 1 and figure 2 As shown, it includes an X servo motor with a position sensor, a Y servo motor with a position sensor, a programmable controller PLC (using Siemens S7-200 series CPU 226DC / DC / DC) and a PC. The photoelectric encoder signal of the servo motor with position sensor (Model Fuji GYS201DC2-T2C) is connected to the servo driver (Model Fuji RYC201D3-VV2), and the servo driver works in position control mode. After the photoelectric code disc signal is converted and processed, it outputs an incremental orthogonal encoding pulse signal, which is used as the input of the two-dimensional motion teaching platform for teaching based on PLC to detect the current position of the motion device and communicate with the corresponding detection signal input terminal of the programmable controller PLC. Each control input terminal of the X-direction servo driver and the Y-direction servo driver i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com