Method for removing film

A thin film and thin film thickness technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of easy damage to the side wall structure and the underlying structure, and achieve the effect of avoiding damage to the underlying structure and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

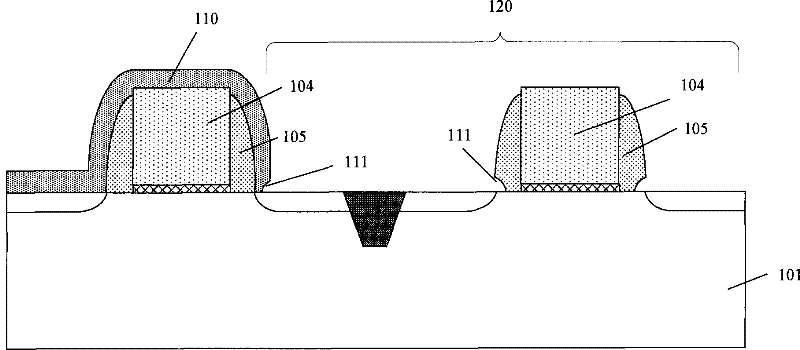

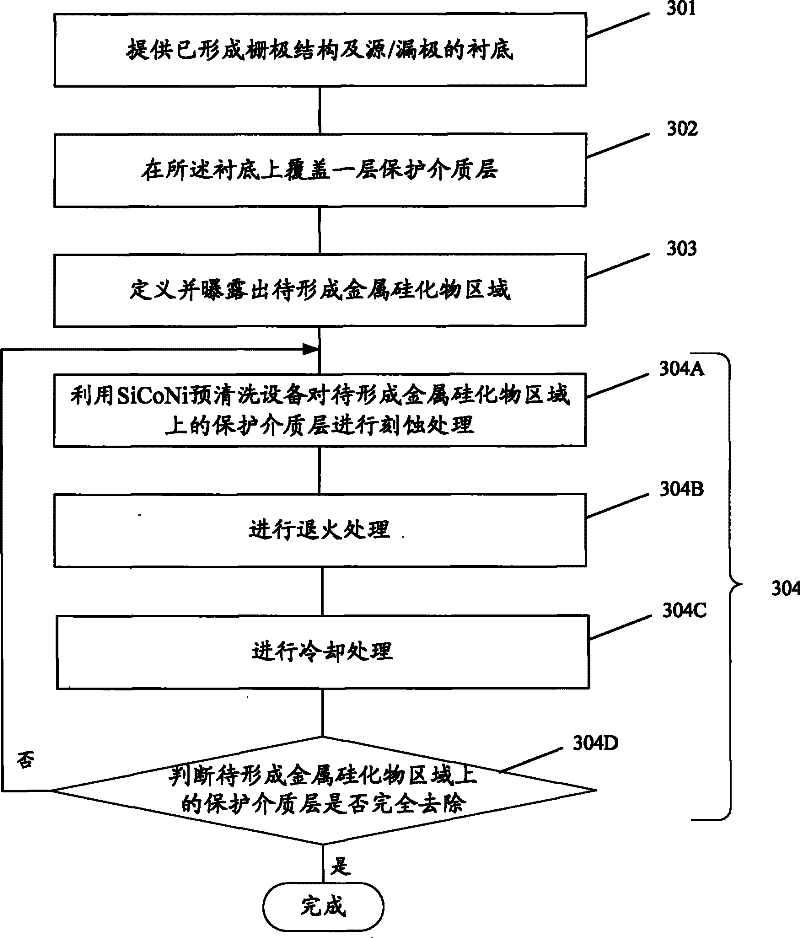

[0125] This embodiment introduces the specific process of removing the protective dielectric layer on the region where the metal silicide is to be formed by using the thin film removing method of the present invention. image 3 It is a flow chart of the thin film removal method for forming localized metal silicide according to the first embodiment of the present invention, Figure 4 to Figure 8 In order to illustrate the device cross-sectional diagram of the thin film removal method for forming localized metal silicides in the first embodiment of the present invention, SiCoNi pre-cleaning equipment is used in this embodiment to realize thin film removal. Combine below Figure 3 to Figure 8 The first embodiment of the present invention will be described in detail.

[0126] Step 301: Provide a substrate on which gate structures and source / drain electrodes have been formed.

[0127] Figure 4 is a schematic cross-sectional view of the substrate provided in the first embodiment...

no. 2 example

[0163] This embodiment introduces the specific process of removing the contact etching stop layer at the bottom of the opening of the contact hole by using the thin film removal method of the present invention. Figure 9 is a flow chart of a thin film removal method for forming a contact hole according to the second embodiment of the present invention, Figure 10 to Figure 15 In order to illustrate the device cross-sectional schematic diagram of the thin film removal method for forming contact holes in the second embodiment of the present invention, the thin film removal in this embodiment is completed by using SiCoNi pre-cleaning equipment, combined below Figure 9 to Figure 15 The second embodiment of the present invention will be described in detail.

[0164] Step 901: Provide a substrate on which a contact etch stop layer has been formed.

[0165] At least one gate structure has been formed on the substrate provided in this embodiment, and a contact etch stop layer has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com