Processing procedure of semiconductor manufactured aluminium metal wire

An aluminum metal and semiconductor technology, which is applied in the field of semiconductor manufacturing aluminum metal wire process, can solve the problems of expanding and expanding the operating voltage and voltage difference, short circuit, etc., to avoid tip discharge and reduce charge accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

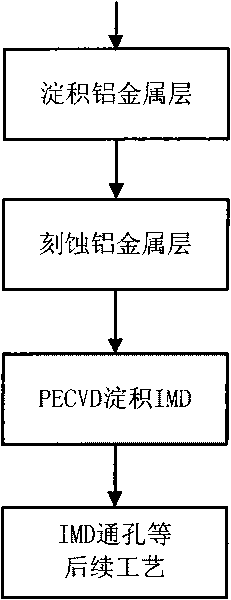

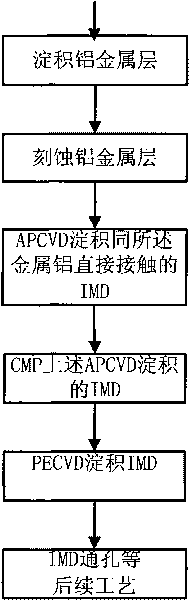

[0022] An embodiment of the semiconductor manufacturing aluminum metal wire process of the present invention is as follows image 3 shown, including the following steps:

[0023] 1. Deposit aluminum metal film;

[0024] 2. Etching the aluminum metal film;

[0025] 3. APCVD (atmospheric pressure chemical vapor deposition) deposits IMD (such as TEOS, orthoethyl silicate) in direct contact with the metal aluminum;

[0026] 4. CMP (Chemical Mechanical Polishing) IMD deposited by APCVD above;

[0027] 5. PECVD deposition IMD;

[0028] 6. Subsequent processes such as IMD through holes.

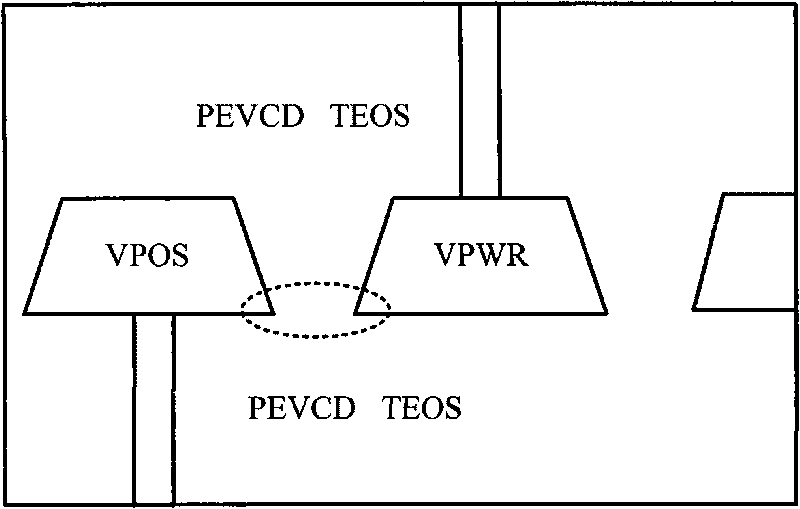

[0029] The semiconductor sectional view of the aluminum metal wire manufacturing process adopting the semiconductor of the present invention is as Figure 4 As shown, APCVD (atmospheric pressure chemical vapor deposition) was used to deposit the IMD in direct contact with the aluminum metal.

[0030] In the semiconductor manufacturing aluminum metal wire process of the present invention, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com