Soil erosion resistance control method

An anti-erosion and soil technology, applied in the direction of soil conditioning materials, soil preparation methods, chemical instruments and methods, etc., can solve the problems of the entire net being washed away, ineffective, troublesome operation, etc., to prevent erosion, prevent soil erosion, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

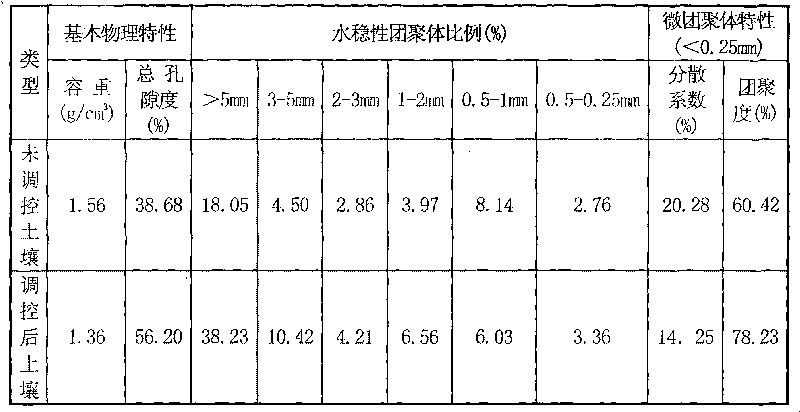

Embodiment 1

[0013] (1) Implementation steps

[0014] 1) The raw materials are 1 part by weight of organic fertilizer starter, 600 parts of edible fungus residue, 23 parts of humic acid, and water, which are put into a hydraulic spraying machine, fully mixed and prepared into a bacterial fertilizer slurry, and Spray evenly on the soil surface, spray thickness ≤ 5mm.

[0015] 2) The raw materials are 20 parts by weight of polyacrylamide, 5 parts of xanthan gum, 50 parts of hemp fiber, and 350 parts of water, which are put into the hydraulic spraying machine, fully mixed to prepare a protective slurry, and uniformly Spray on the treated soil surface in step 1), with a spray thickness≤3mm.

[0016] 3) The raw materials are 30 parts by weight of straw green material (corn stalk), 200 parts of water, and 1.5 parts of cellulase, which are put into a mechanically stirred fermenter, fully stirred, and heated at a temperature of 50 ° C. Keep it for 3 days, during which it is fully stirred once a ...

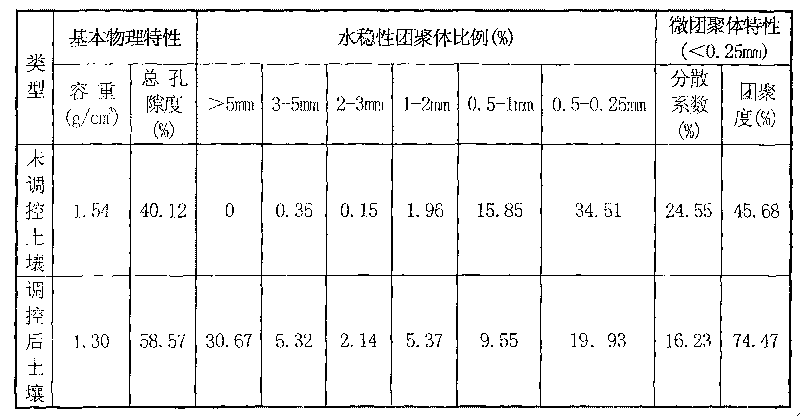

Embodiment 2

[0026] (1) Implementation steps

[0027] 1) The raw materials are 1 part by weight of organic fertilizer starter, 800 parts of edible fungus residue, 30 parts of humic acid, and 4500 parts of water, which are put into a hydraulic spraying machine, fully mixed and prepared into a bacterial fertilizer slurry. And evenly spray on the soil surface, spray thickness ≤ 5mm.

[0028] 2) The raw materials are 10 parts by weight of polyacrylamide, 10 parts of xanthan gum, 80 parts of hemp fiber, and 500 parts of water, which are put into a hydraulic spraying machine, fully mixed to prepare a protective slurry, and uniformly Spray on the treated soil surface in step 1), with a spray thickness≤3mm.

[0029] 3) The raw materials are 20 parts by weight of straw green material (corn stalk, sorghum stalk), 120 parts of water, and 1 part of cellulase, which are put into a mechanically stirred fermenter, fully stirred, and heated at 50 ° C. The temperature is maintained for 3 days, during whi...

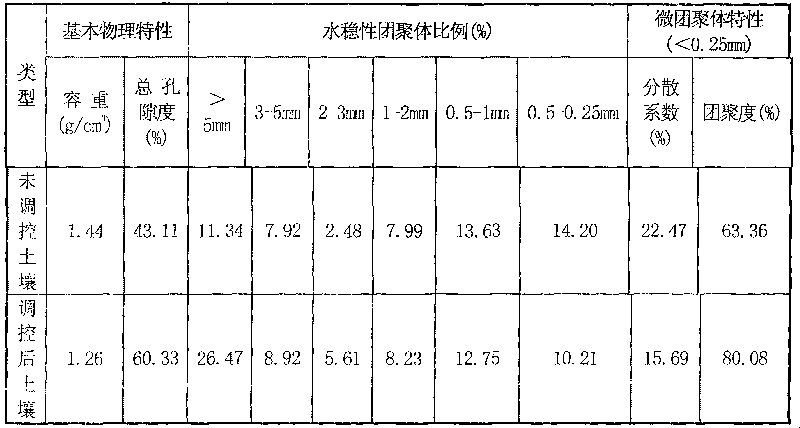

Embodiment 3

[0039] (1) Implementation steps

[0040] 1) The raw materials are 1 part of organic fertilizer starter, 700 parts of edible fungus residue, 15 parts of humic acid, and 3800 parts of water, which are put into a hydraulic spraying machine, fully mixed and prepared into a bacterial fertilizer slurry. And evenly spray on the soil surface, spray thickness ≤ 5mm.

[0041] 2) The raw materials are 15 parts by weight of polyacrylamide, 7 parts of xanthan gum, 30 parts of hemp fiber, and 250 parts of water, which are put into the hydraulic spraying machine, fully mixed to prepare a protective slurry, and uniformly Spray on the treated soil surface in step 1), with a spray thickness≤3mm.

[0042] 3) The raw materials are 25 parts by weight of straw green material (corn stalk, sorghum stalk, wheat straw), 160 parts of water, and 1 part of cellulase, which are put into a mechanical stirring fermenter and fully stirred evenly , and kept at a temperature of 48° C. for 5 days, during which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap