Visible-light response vanadium-samarium composite oxide catalyst, preparation method thereof and application thereof

A composite oxide and catalyst technology, applied in the field of new visible light responsive catalyst and preparation, can solve the problem of low catalytic activity, achieve high visible light absorption ability, less harsh application conditions, and high visible light degradation activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

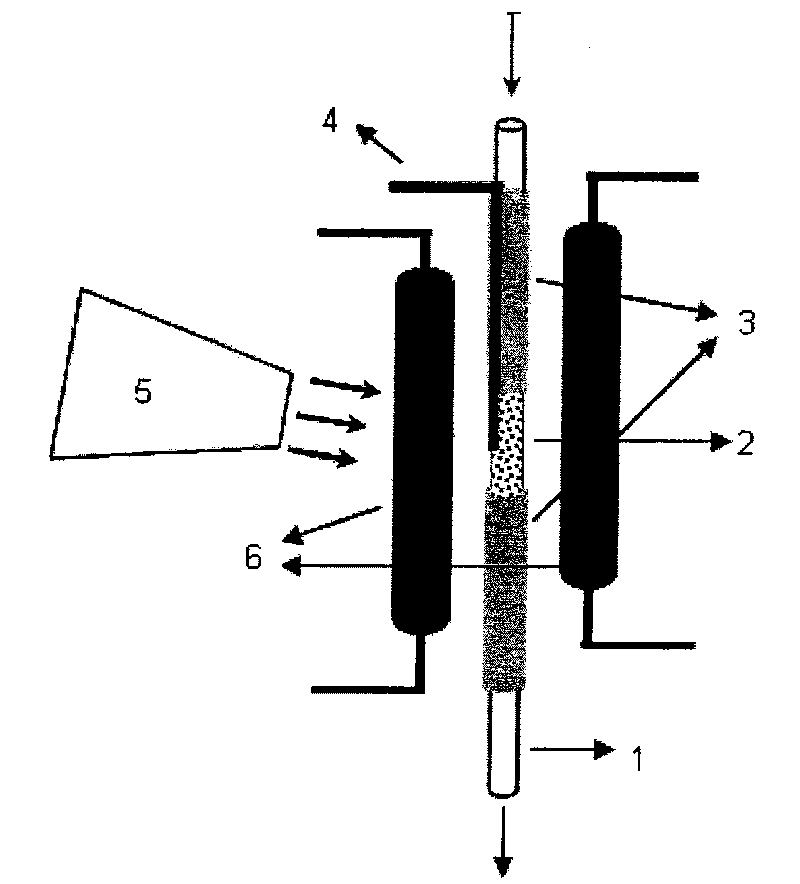

Method used

Image

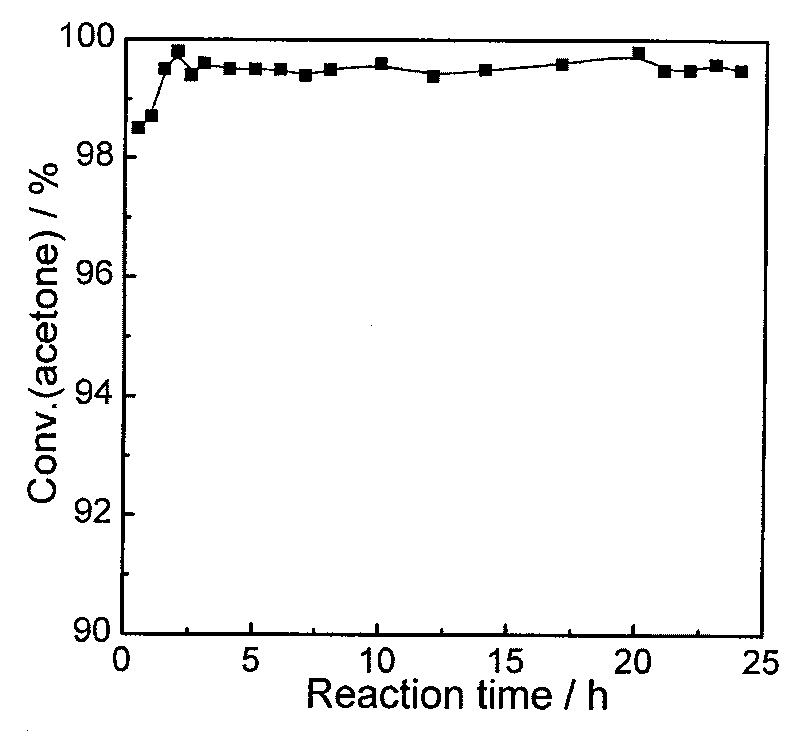

Examples

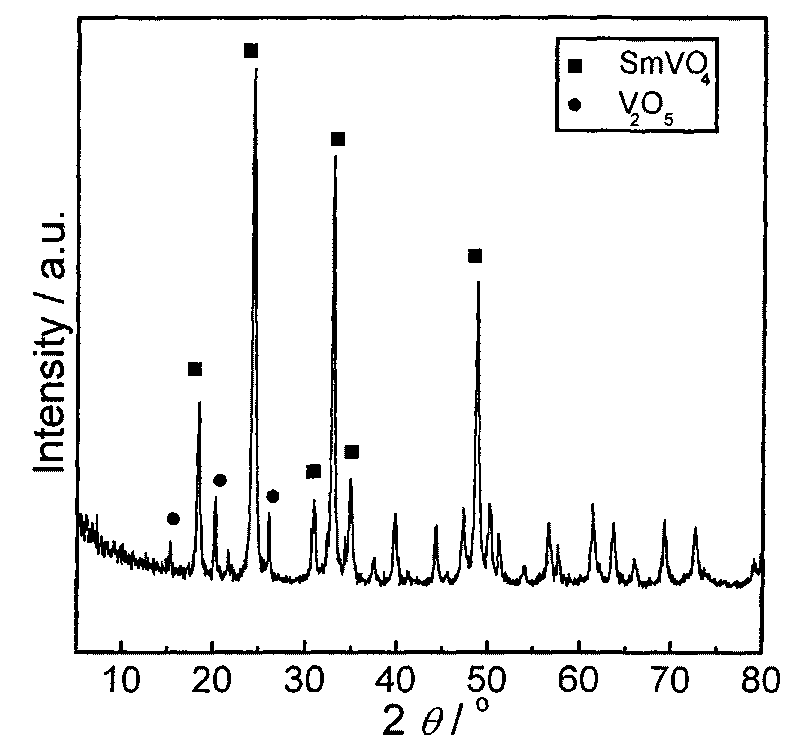

Embodiment 1

[0022] Weigh 1.073 g of ammonium metavanadate, add 50 ml of deionized water, stir and dissolve in a water bath at 80° C., and obtain an ammonium metavanadate solution. Weigh 2.0 g of samarium oxide, add 3 ml of concentrated nitric acid and 7 ml of deionized water, stir and dissolve in a water bath at 80° C. to obtain a samarium nitrate solution. Then slowly add the samarium nitrate solution dropwise to the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate. After stirring and aging for 2 hours, the water in the solution is removed by rotary evaporation, and the obtained solid is dried in an oven at 90°C. , and finally baked in a muffle furnace at 500°C for 4 hours. After natural cooling, the 0.8VSmO catalyst prepared by the precipitation method was obtained.

Embodiment 2

[0024] Weigh 1.342 g of ammonium metavanadate, add 50 ml of deionized water, stir and dissolve in a water bath at 80° C., and obtain an ammonium metavanadate solution. Weigh 2.0 g of samarium oxide, add 3 ml of concentrated nitric acid and 7 ml of deionized water, stir and dissolve in a water bath at 80° C. to obtain a samarium nitrate solution. Then slowly add the samarium nitrate solution dropwise to the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate. After stirring and aging for 2 hours, the water in the solution is removed by rotary evaporation, and the obtained solid is dried in an oven at 90°C. , and finally baked in a muffle furnace at 500°C for 4 hours. After natural cooling, the 1.0VSmO catalyst prepared by the precipitation method was obtained.

Embodiment 3

[0026] Weigh 1.811 g of ammonium metavanadate, add 60 ml of deionized water, stir and dissolve in a water bath at 80° C., and obtain an ammonium metavanadate solution. Weigh 1.80 g of samarium oxide, add 2 ml of concentrated nitric acid and 8 ml of deionized water, stir and dissolve in a water bath at 80° C., and obtain a samarium nitrate solution. Then slowly add the samarium nitrate solution dropwise to the ammonium metavanadate solution under the condition of stirring to form a yellow precipitate. After stirring and aging for 2 hours, the water in the solution is removed by rotary evaporation, and the obtained solid is dried in an oven at 90°C. , and finally baked in a muffle furnace at 500°C for 4 hours. After natural cooling, the 1.5VSmO catalyst was prepared by precipitation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com