Processing method for surface coating

A processing method and surface coating technology, which can be used in devices for coating liquids on surfaces, surface pretreatment, metal processing equipment, etc., which can solve the problems of generating more waste gas and waste water, difficult demoulding of finished products, and lack of lubrication of molds. , to achieve the effect of reducing defective products, reducing surface temperature, and reducing the occurrence of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

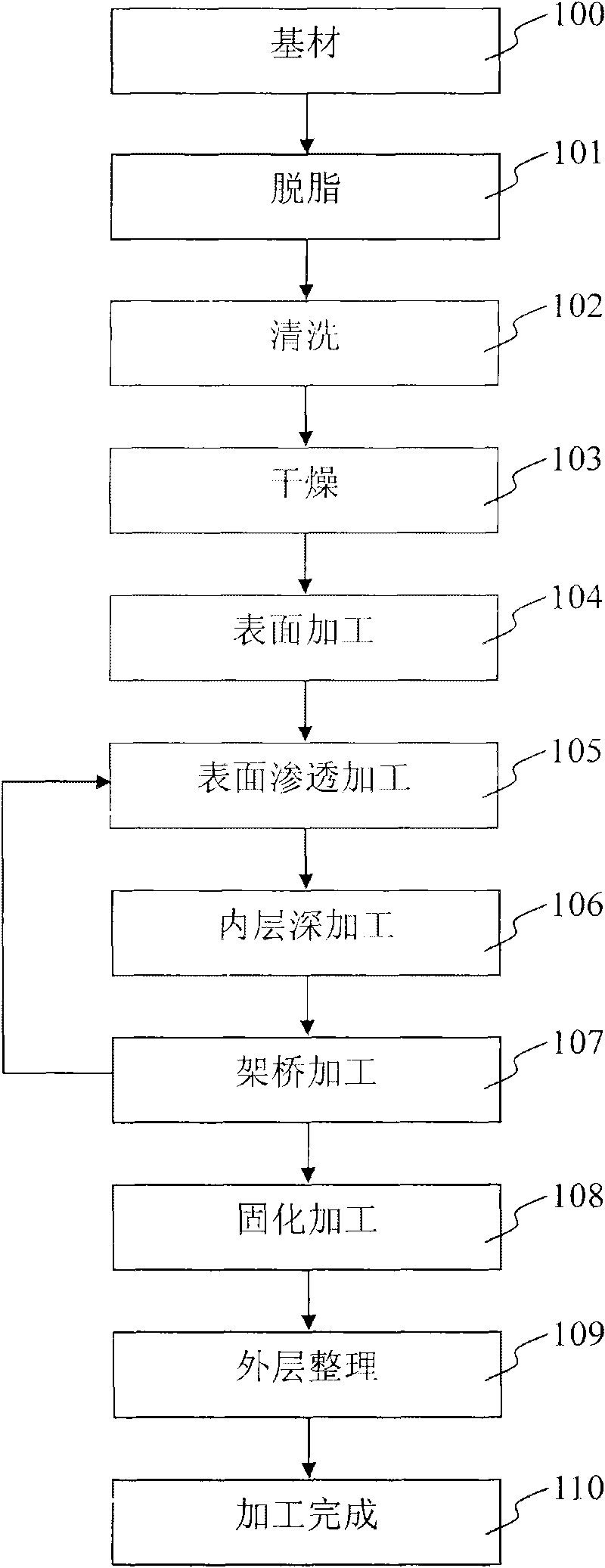

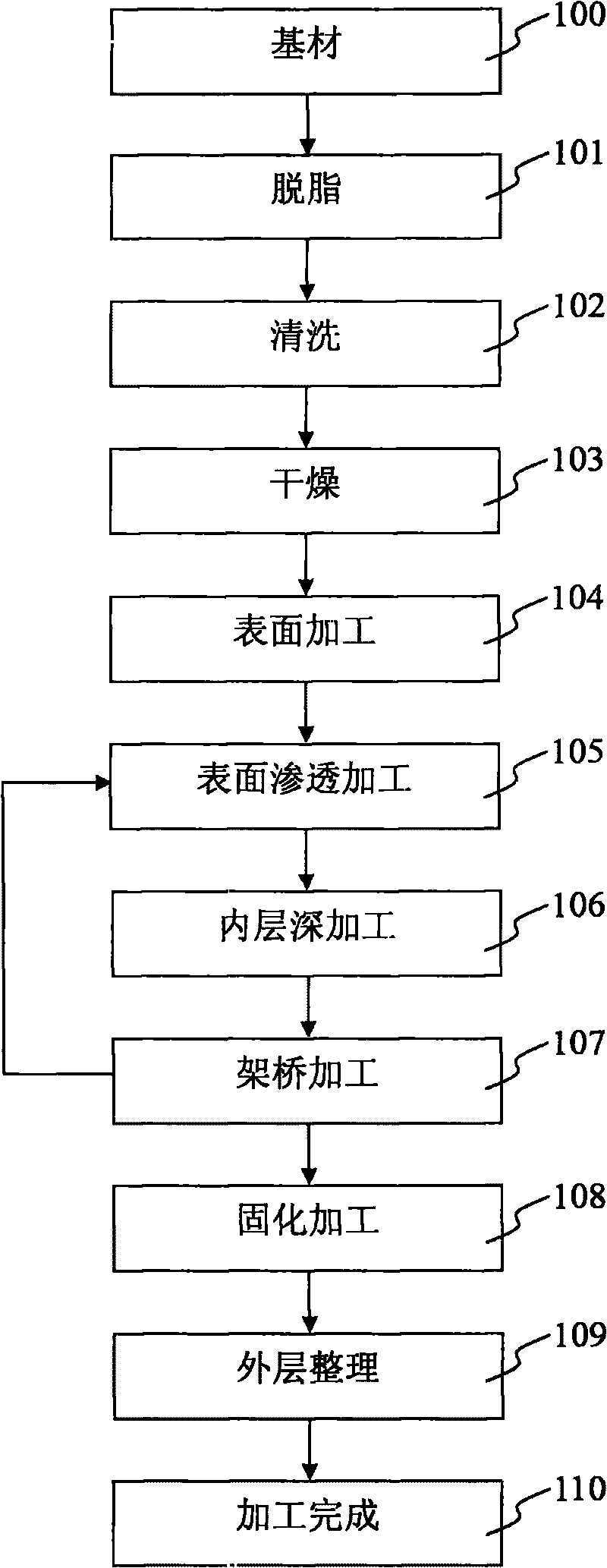

[0026] In the embodiment of the present invention, the selected base material is a mold for continuous precision injection molding and its accessories, such as ejector pins, inserts, cores, bushings, punches, inserts, and forming and bending accessories. Such as figure 1As shown, the mold and its accessories are first subjected to the pretreatment steps of degreasing 101, cleaning 102, and drying 103, respectively, to remove oil or impurities attached to the surface of the mold and its accessories; and its accessories are placed at a temperature of 120°C to 250°C for surface processing 104, so that the capillary pores on the surface of the mold and its accessories can be gradually expanded; then, a treatment agent including nanoparticles is applied to the mold and its accessories The surface of the accessory is subjected to surface penetration processing 105, wherein the composition ratio of the treatment agent is between 10 to 40% by weight of titanium dioxide, 5 to 15% by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com