Powder spray marking device of cutting machine

A scribing device and cutting machine technology, applied in the direction of feeding device, automatic control device, metal processing machinery parts, etc., can solve the problems of scribing and cutting line deviation, difficulty, cutting line and powder spraying line can not overlap, etc., to achieve Effects of reducing shaking, avoiding deviation, increasing speed and shipbuilding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

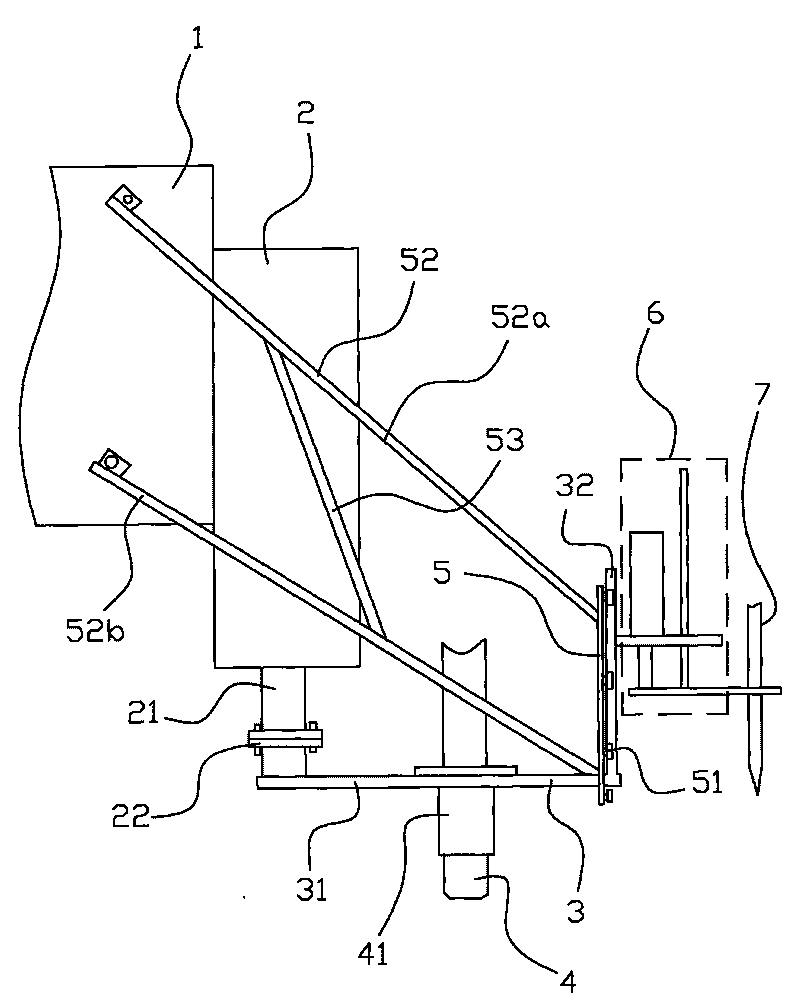

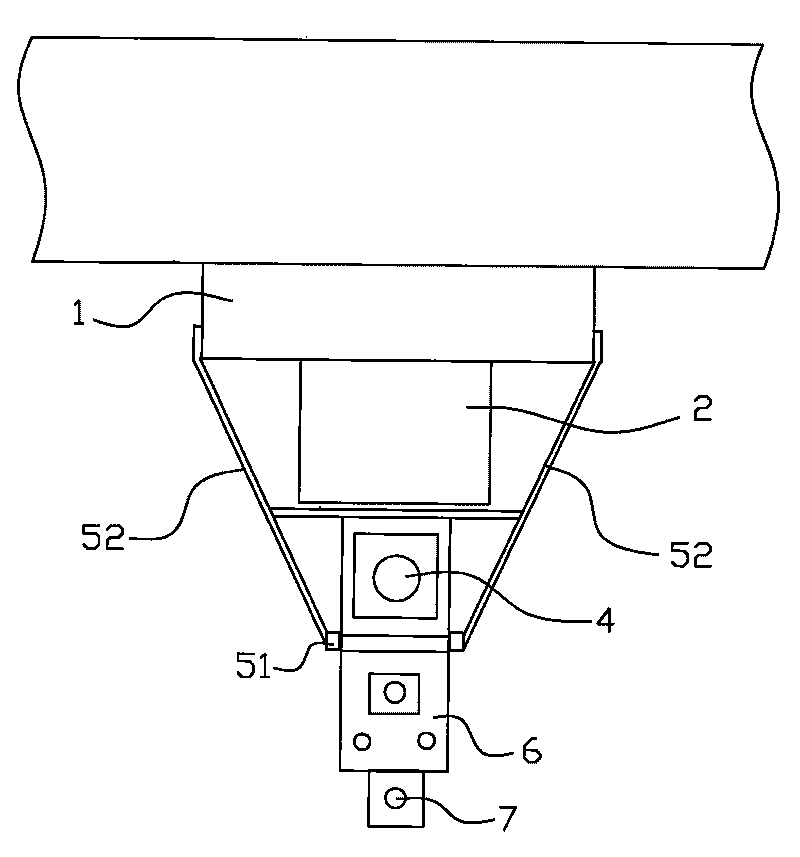

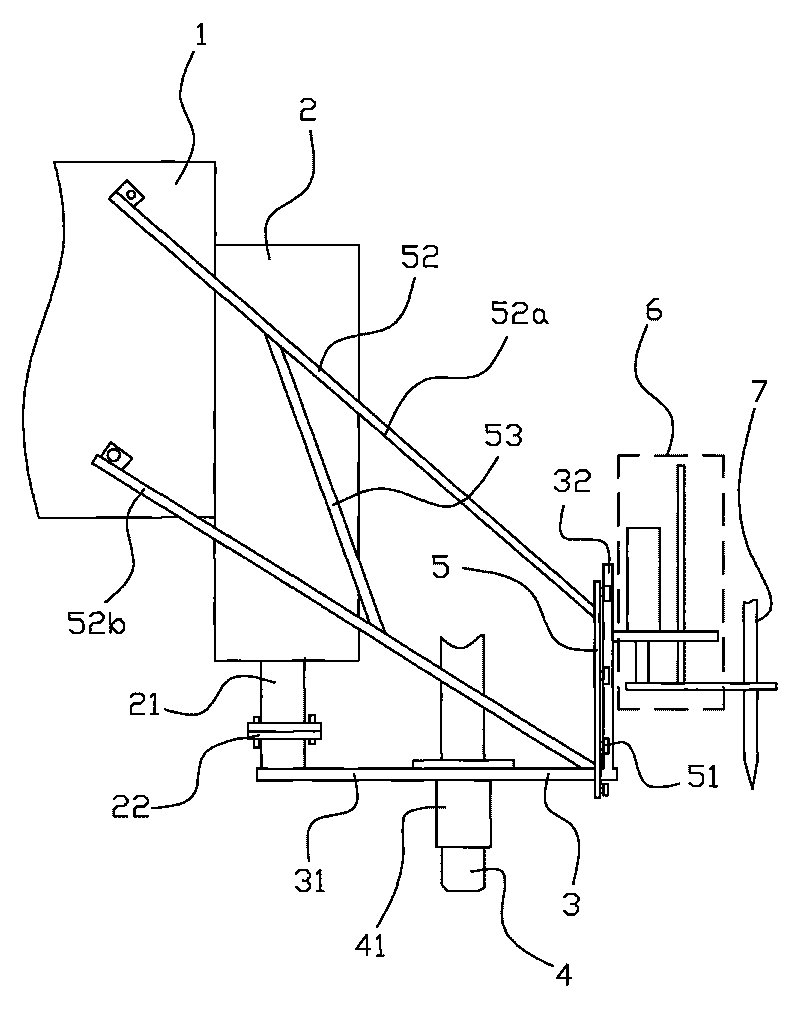

[0016] Such as figure 1 and figure 2 As shown, the powder spraying and scribing device of the cutting machine in this embodiment includes a cutting gun 4 , a powder spraying gun 7 and a lifter 2 , and the lifter 2 is fixed to the trolley 1 . The powder spraying gun 7 is arranged in the powder spraying device 6, and the cutting gun 4 is arranged in the supporting plate 3, and one end of the supporting plate 3 is connected with the lifting shaft 21 which can move up and down in the lifter 2 through the cast iron flange 22. Connect, and the other end of pallet 3 is connected with powder spraying device 6. The powder spraying and scribing device also includes a positioning frame, which is two vertically arranged track bars 5, and the two track bars 5 are fixed to the corresponding two sides of the walking trolley 1 through the fixing bars 52 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com