Electro-rheological pendulum shaft cylindrical polishing device

A polishing device and electrorheological technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. speed, improved material removal efficiency, and the effect of avoiding power line breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

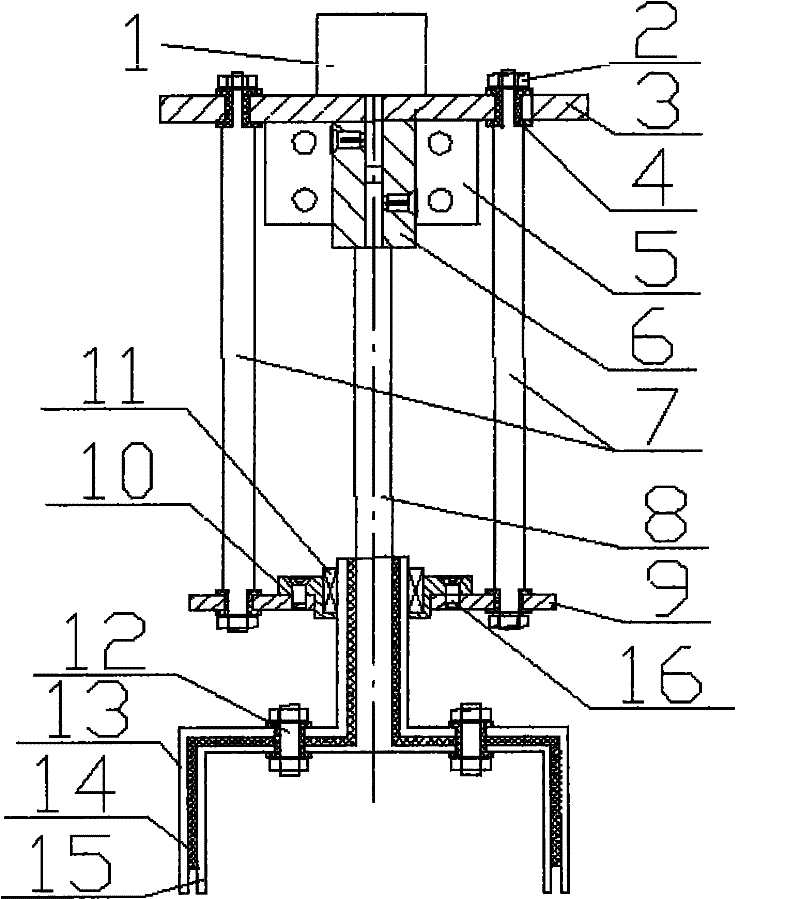

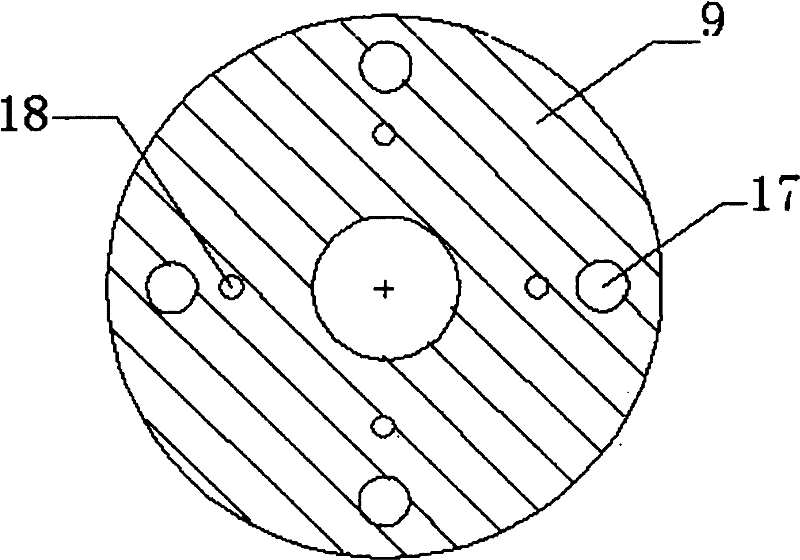

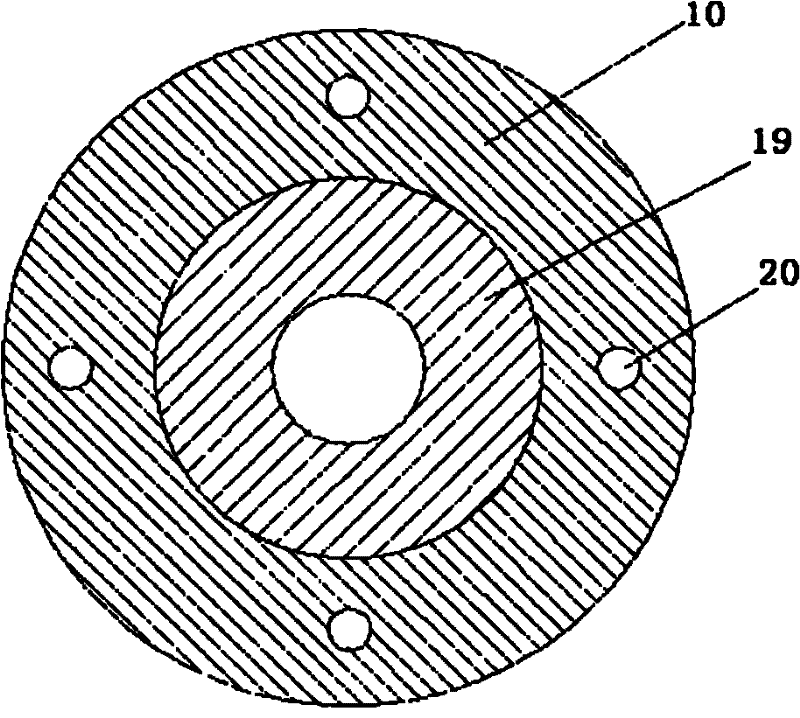

[0027] Such as figure 1 As shown, it is a schematic cross-sectional structure diagram of an electrorheological pendulum cylinder polishing device of the present invention, as can be seen from the figure, it mainly consists of a motor 1, a nut 2, a bracket seat 3, an insulating sleeve 4, and an adapter plate 5 , coupling 6, connecting rod 7, rotating shaft 8, base 9, brush cover 10, ring brush 11, bolt 12, anode polishing cylinder 13, insulating cylinder 14, cathode polishing cylinder 15, screw 16 Composition; the motor 1 is installed on the support base 3 through positioning slots and screws; the support base 3 is fixed on the ultra-precision CNC machine tool through the adapter plate 5 on it, so as to control the movement of the support base according to a certain track; the upper end of the rotating shaft 8 passes through Coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com