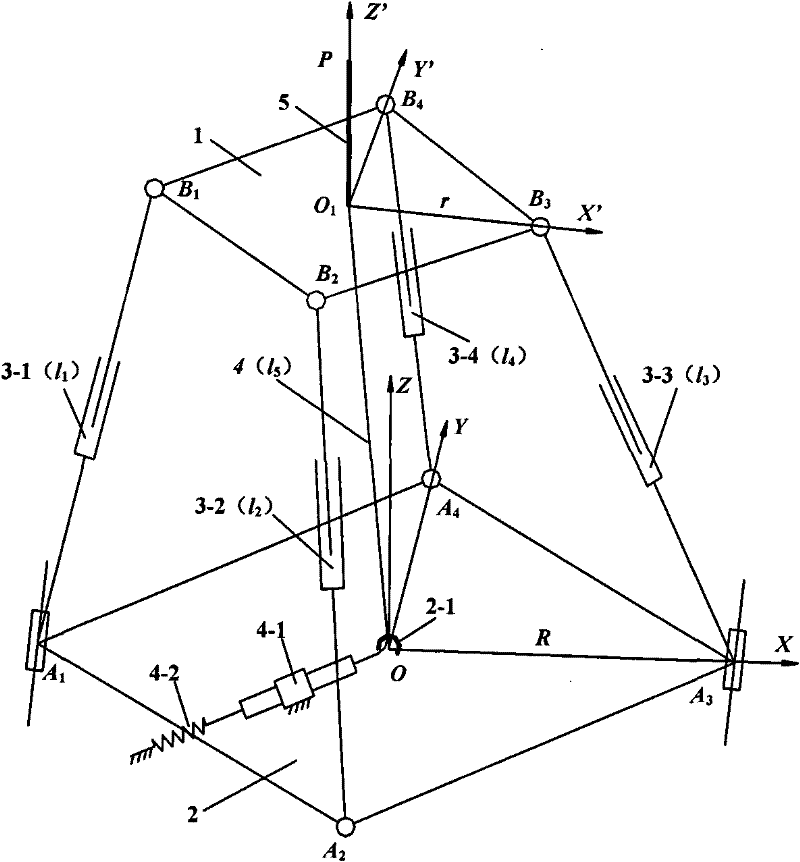

Parallel robot device with functions of fault tolerance and fault correction and fault tolerating and correcting method thereof

A robot and parallel technology, applied in the direction of manipulator, program-controlled manipulator, digital control, etc., can solve the problems of low motion quality, reduced position and speed control accuracy, out of control of parallel robots, etc. high-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

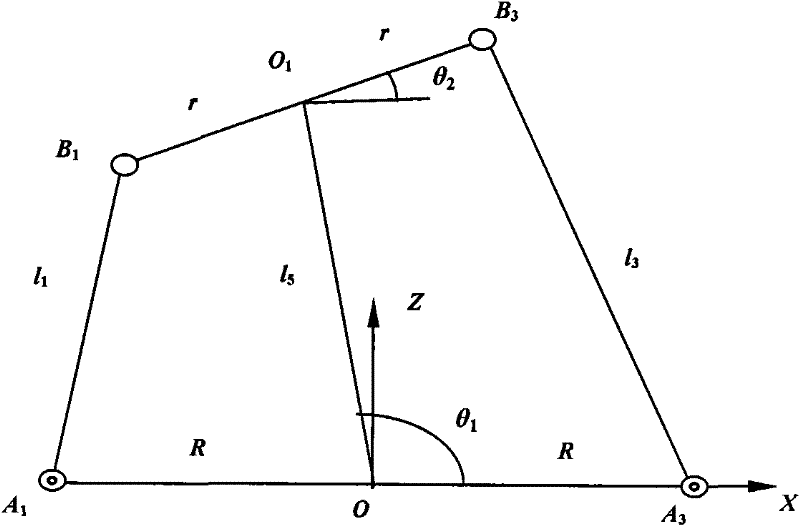

Method used

Image

Examples

Embodiment Construction

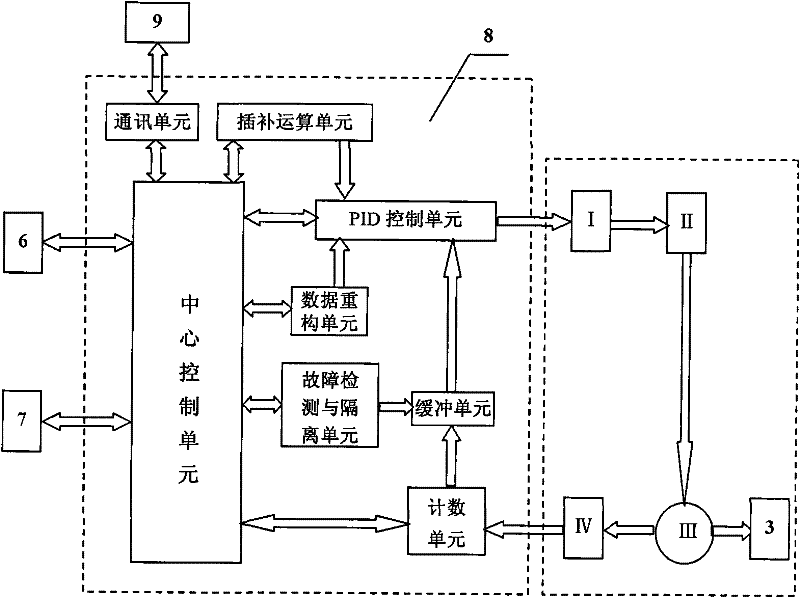

[0016] In the control system of the present embodiment: the FPGA logic controller 8 adopts the FPGA logic device of the model SPARTAN-3 and through the reconfiguration of internal logic resources, the composition includes a central control unit, a communication unit, an interpolation operation unit, a PID control unit, Controller including data reconstruction unit, fault detection and isolation unit, counting unit, and buffer unit; flash memory (FLASH) 6 model is Am29LV160D, random access memory (RAM) 7 adopts synchronous dynamic random access memory model HY57V641620HG Take the memory, the model of the digital-to-analog converter I is AD7564, the model of the servo motor III is MSMA042A1G, the model of the matching servo driver II is MSDA043A1A, and the model of the driving leg sensor IV is a photoelectric encoder of CN65M121759.

[0017]In this embodiment, the error tolerance and automatic error correction method for sensor failure is taken as an example in the parallel robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com