Deviation-preventing controller for tyre crane

A controller and anti-deviation technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as box collision accidents and difficulties, achieve the goal of reducing labor intensity, reducing collision accidents, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

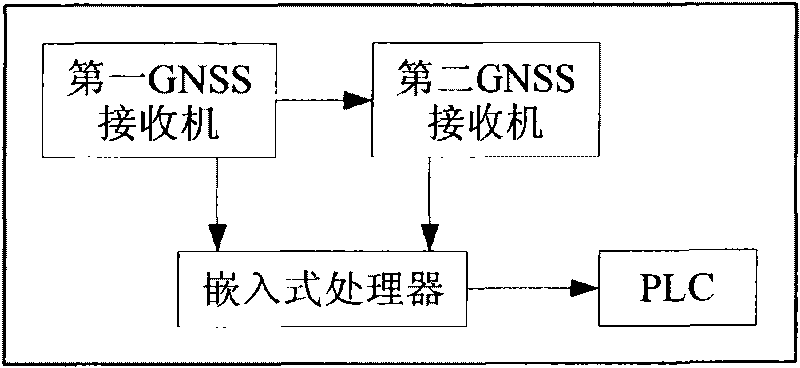

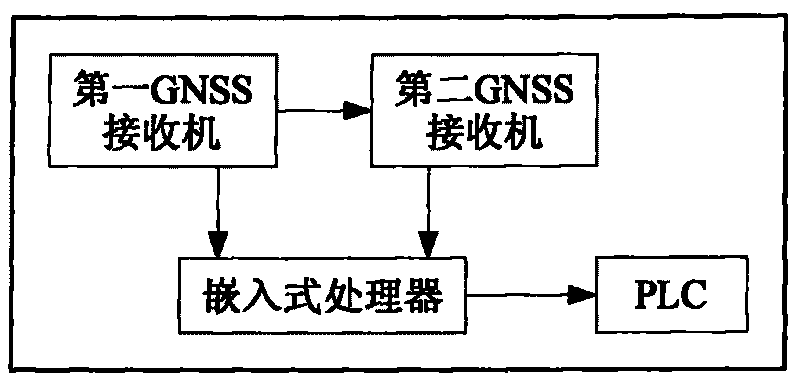

[0026] Embodiment 1, RTG anti-deviation controller, such as figure 1 shown, including:

[0027] The first and second GNSS receivers, the antennas of which are installed on the side of the electrical room or power room of the RTG cart, are used to output the first and second GNSS information respectively;

[0028] An embedded processor, configured to calculate, respectively, the first and second horizontal distances of the first and second GNSS receivers from the orbit reference line according to the first and second GNSS information;

[0029] PLC (Programmable Logic Controller, Programmable Logic Controller), configured to adjust the traveling direction of the RTG cart according to the first and second horizontal distances.

[0030] In this embodiment, the embedded processor may be, but not limited to, an ARM processor.

[0031] In an implementation manner of this embodiment, the antennas of the first and second GNSS receivers can be, but not limited to, installed on the roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com