Gear lubricant and preparation method thereof

A lubricant and gear technology, applied in the field of new gear lubricants and their preparation, to achieve the effects of excellent lubricity, energy saving and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

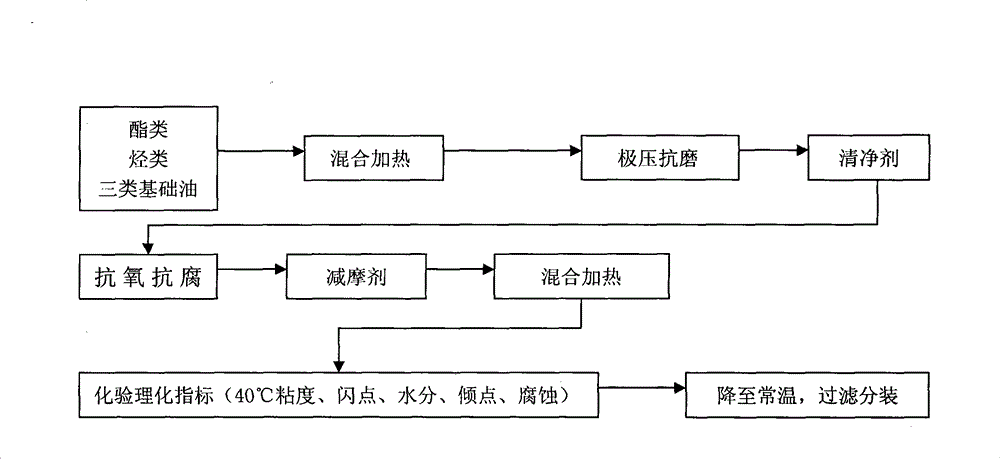

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Weigh the following raw materials: NP3435kg, PAO12 30kg and 150N 30kg, add them into the container and heat and mix them, the temperature rises to 70°C and continue heating for 50 minutes, then in turn 8kg of extreme pressure antiwear agent, 4kg of detergent, antioxidant and anti-oxidant Mix 4kg of antiseptic and 7kg of boron-nitrogen compound and heat for 40 minutes, test the physical and chemical indicators, cool down to normal temperature after reaching the indicators, filter and pack.

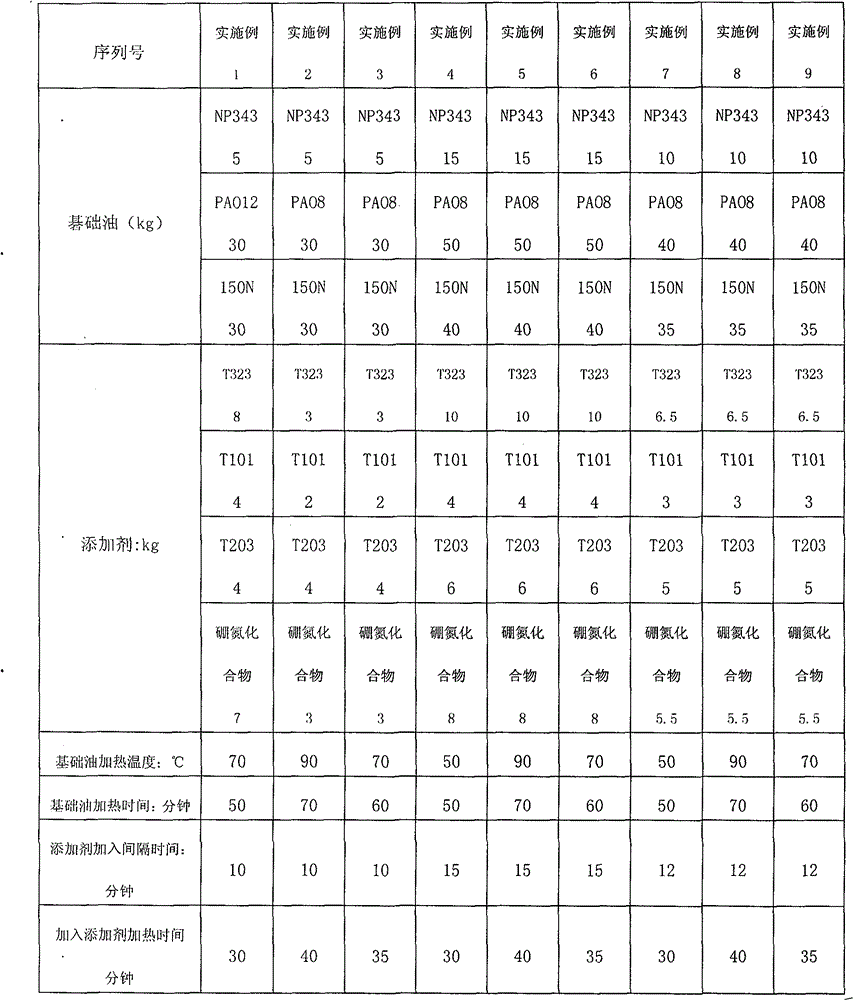

[0021] Table 1 and Table 2 are lists of embodiments of the present invention.

[0022] Table 1 is a list of embodiments of the present invention

[0023]

[0024] Table 1

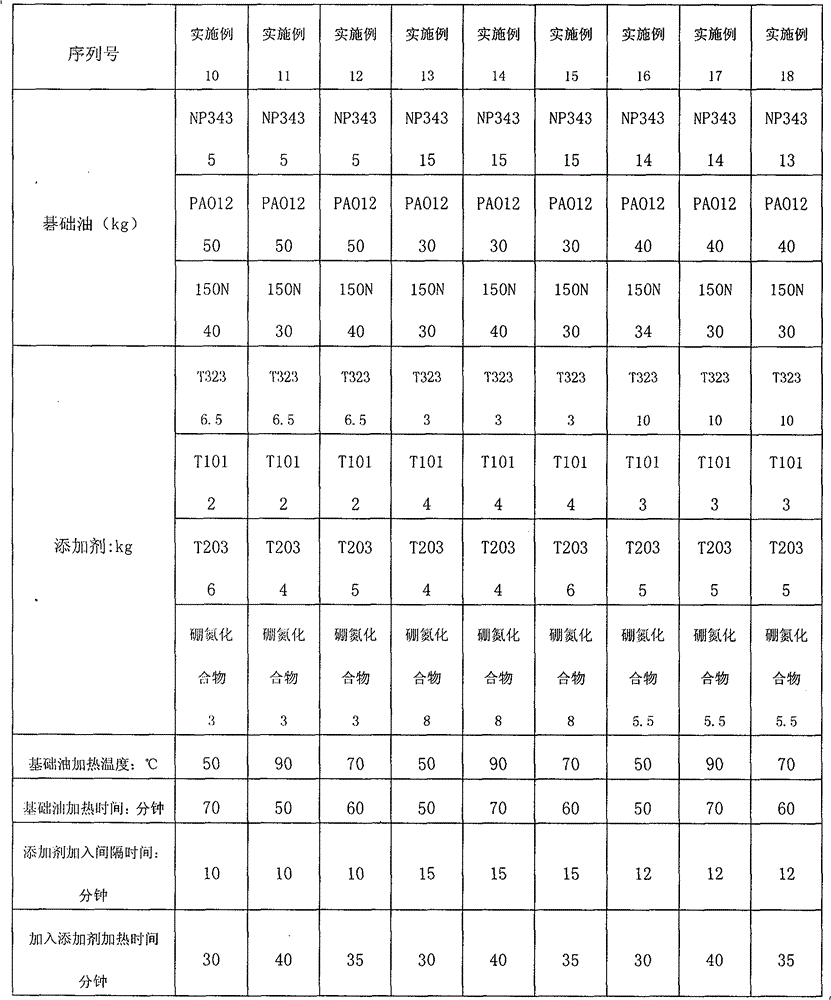

[0025] Table 2 is a list of embodiments of the present invention

[0026]

[0027] Table 2

[0028] The esters in the above examples can be replaced by one or more of NP343, NP372 and P81, the hydrocarbons are one or more of PAO8, PAO10 and PAO12, and the three types of oil are 150NN, 100N, 75N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com