Device and method for arranging a plurality of cells at same plane and controlling cells

A cell and unified technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of inelasticity of gold flakes, limited price and application, expensive absorption of gold flakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1) Preparation of polydimethylsiloxane stamp:

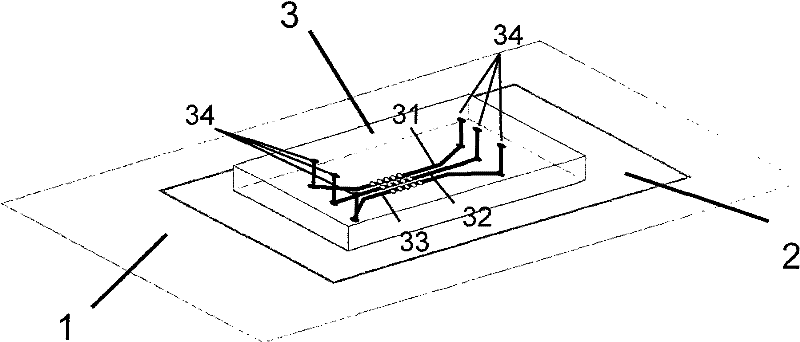

[0064] Use photolithography to prepare at least one group of convex linear microstructure units on a silicon wafer (the present embodiment figure 1 shown three convex lines), first use the drawing software L-edit to design the desired graphics: three convex line bands (the middle convex line band at the middle position, and the convex line bands located on both sides of the middle convex line band respectively) side convex lines), the length of the convex lines is 1.2 cm, the middle sections of the convex lines on both sides are respectively parallel to the middle convex lines, and the middle sections of the convex lines on both sides are The two ends outside are inclined away from the direction of the middle convex line (the length is 0.5 cm, whose length is this?), the interval between the two convex lines is 200 microns, and each convex line The tape width is 400 microns;

[0065] Using the above-mentioned silicon chi...

Embodiment 2

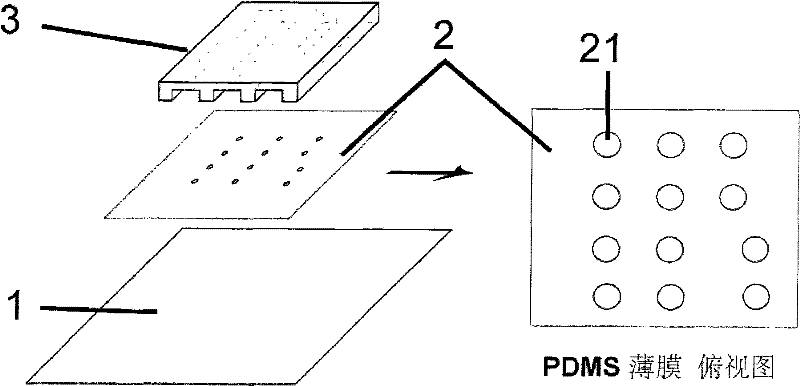

[0080] 1) Use photolithography to prepare at least one set of convex linear microstructure units on the silicon wafer, first use the graphics software L-edit to design the desired pattern: three parallel convex lines and a circular array of convex structures , the length of the three convex strips is 1.2 cm, the outer two ends are inclined outwards, the length is 0.5 cm, the middle part is parallel, the distance between each other is 200 microns, and the width of each strip is 400 microns. The circular micro-column array has three columns with a diameter of 300 microns and a height of 100 microns, each column has ten micro-columns, and the interval between each column is 300 microns, and the space between the columns in each column is also 300 microns.

[0081] 2) Flipping the convex linear microstructure unit obtained in step 1) with polydimethylsiloxane (PDMS) to obtain a PDMS stamp with a concave pattern corresponding to the above microstructure.

[0082] 3) Spread unpolyme...

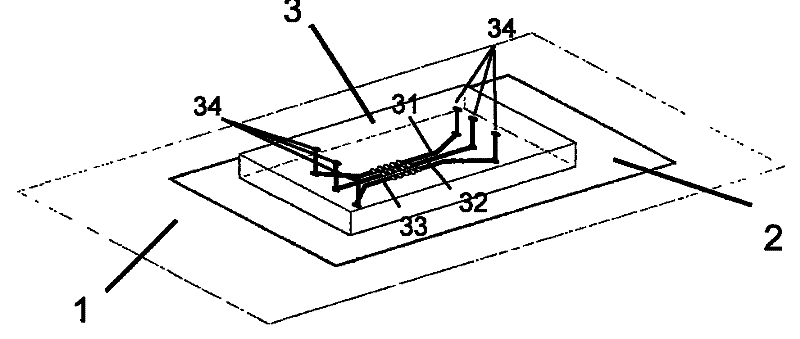

Embodiment 3

[0090] 1) Use photolithography to prepare at least one set of convex linear microstructure units on the silicon wafer, first use the graphics software L-edit to design the desired pattern: three parallel convex lines and a circular array of convex structures , the length of the three convex strips is 1.2 cm, the outer two ends are inclined outward, the length is 0.5 cm, the middle part is parallel, and the distance between each other is 200 microns, the width of the first and second strips is 400 microns, and the width of the third strip is 1 mm. The circular micropillar array is three columns, with a diameter of 300 microns and a height of 100 microns, with four microcolumns in each column, such as figure 2As shown, the interval between each column is 300 microns, and the interval between the columns is also 300 microns. The interval between the first two columns of the third column and the second column is 300 microns, and the interval between the last two columns and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com