A kind of collagen-based self-healing hydrogel and preparation method thereof

A self-healing and hydrogel technology, applied in the field of collagen materials, can solve the problems of non-self-healing, easy to be destroyed, endangering the health and safety of patients, etc., and achieve the effect of good toughness and self-healing, and a good cell living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

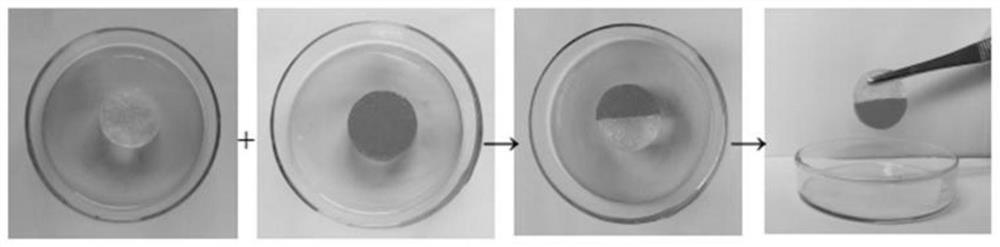

Image

Examples

preparation example Construction

[0030] A preparation method of collagen-based self-repairing hydrogel, which comprises the following specific steps:

[0031] (1) Dissolve collagen in an acetic acid solution with a concentration of 0.01-0.1 mol / L, and then stir evenly to prepare a collagen solution with a mass concentration of 10-30 mg / mL;

[0032] (2) Pipette guar gum and dialdehyde guar gum at a ratio of 0.5 to 4:1 by mass ratio and dissolve them in deionized water at the same time, and then dissolve them in deionized water at 30 to 80 Stirring and mixing for 2 to 6 h under the temperature condition of ℃ to prepare a guar gum / dialdehyde guar gum compound solution with a total mass concentration of 10 to 30 mg / mL;

[0033] (3) Dissolving borax in PBS buffer solution to prepare a borax solution with a mass concentration of 0.05-0.2 mol / L;

[0034] (4) Blend the collagen solution prepared in step (1) with equal mass concentration and the guar gum / dialdehyde guar gum compound solution prepared in step (2) in p...

Embodiment 1

[0044] (1) Dissolve 5 g of guar gum in 50 mL of ethanol, add 40 mL of NaIO with a concentration of 0.1 mol / L 4 solution, and react in the dark at room temperature for 12 h; after the oxidation reaction is completed, add 0.5 mL ethylene glycol solution to the mixed solution to terminate the reaction, and stir at room temperature for 0.5 h; wash the reaction product 3 times with tert-butanol, wash After cleaning, it was subjected to vacuum freezing treatment for 12 h, and then the processed product was ground to obtain powdered formylated guar gum with a degree of formylation of 4%.

[0045] (2) Cut the cowhide into small pieces, put it into a meat grinder and grind it, then put the ground cowhide with a wet weight of about 10g into a 1 L Erlenmeyer flask, and add pepsin equivalent to 3% of the wet weight of the cowhide and 500 mL of acetic acid with a concentration of 0.1 mol / L, and then put it into a constant temperature shaker at 4 ℃ for vibration extraction at a speed of 180...

Embodiment 2

[0051] (1) Dissolve 10 g of guar gum in 50 mL of ethanol, add 40 mL of 0.5 mol / L NaIO 4 solution, and reacted in the dark for 24 h at room temperature; after the oxidation reaction was completed, 2 mL of ethylene glycol solution was added to the product to terminate the reaction, and stirred at room temperature for 2 h; Vacuum freeze treatment for 24 h, and then grind the processed product to obtain powdered formylated guar gum, with a degree of formylation of 8%;

[0052] (2) Cut the cowhide into small pieces, put it into a meat grinder and grind it, put the ground cowhide with a wet weight of about 10 g into a 1 L Erlenmeyer flask, add pepsin equivalent to 3% of the wet weight of the cowhide and 500 mL of acetic acid with a concentration of 0.5 mol / L, and then put it into a constant temperature shaker at 4 ℃ for vibration extraction at a speed of 180 r / min for 72 h. The solution extracted by shaking was centrifuged, salted out, and centrifuged again, and then dissolved in 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com