Heating method of weather-proof sheet billet

A heating method and steel slab technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems affecting the mechanical properties of products, unsatisfactory effects, and damage to main rolling line equipment, and achieve significant economic and social benefits. Improve the qualified rate of furnace descaling and improve the quality of surface material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

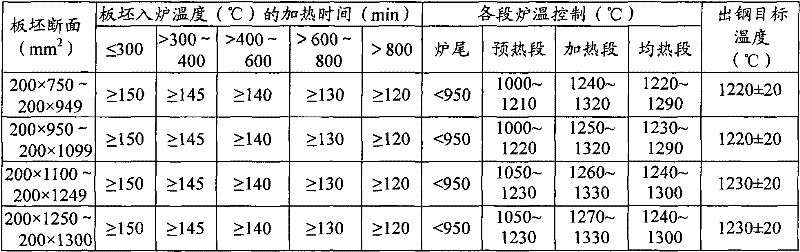

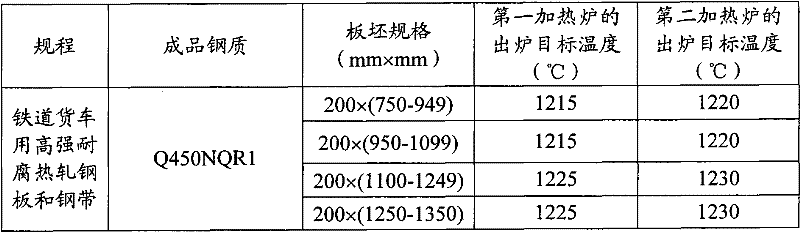

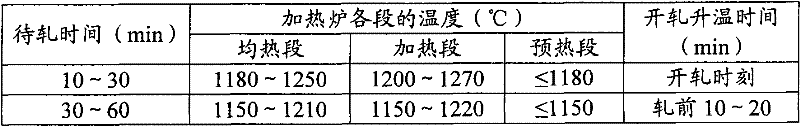

Method used

Image

Examples

Embodiment 1

[0044] A total of 782 weather-resistant steel slabs with a size of 200mm×1250mm×L are heated by the technology of the present invention. The average temperature of the slabs is 1215°C, which is 11°C lower than that of the existing technology; the average temperature of the heating section is 1271°C, which is higher than that of the existing technology. The technology is 12°C lower than the technology, and the average temperature of the soaking section is 1244°C, which is 9°C lower than that of the existing technology. The heating time of the slab at different furnace temperatures is only 1-2 minutes longer than the specified time, which is significantly shorter than that of the existing technology; The average temperature of slabs in the first heating furnace is 1211°C, and the average temperature of slabs in the second heating furnace is 1217°C. The temperature of slabs in the second heating furnace is 6 times higher than that in the first heating furnace. °C, which is 4.8 °C ...

Embodiment 2

[0053] Using the technology of the present invention to heat 100 weather-resistant steel slabs with a section of 200mm×1200mm, the average temperature of the slabs is 1237°C, and the average temperatures of the preheating section, heating section and preheating section of the heating furnace are respectively 1087°C and 1280°C and 1273°C, wherein the average air-to-coal ratio of the upper section of the heating section of the heating furnace is 2.15, and the average air-to-coal ratio of the lower section of the heating section is 2.02. According to statistics, the qualified rate of descaling of these 100 pieces of furnace scale is as high as 96.4%.

Embodiment 3

[0055] Using the technology of the present invention to heat 100 weather-resistant steel slabs with a section of 200mm×920mm, the average temperature of the slabs is 1205°C, and the average temperatures of the preheating section, heating section and preheating section of the heating furnace are respectively 1087°C and 1252°C and 1233°C, wherein the average air-to-coal ratio of the upper section of the heating section of the heating furnace is 2.05, and the average air-to-coal ratio of the lower section of the heating section is 1.98. According to statistics, the qualified rate of descaling of these 100 pieces of furnace scale is as high as 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com