High-strength cast steel for coupler of railway vehicle and manufacturing method thereof

A technology for railway vehicles and manufacturing methods, which is applied in the field of high-strength cast steel for couplers, can solve problems such as being unable to adapt to heavy-duty railway transportation, and achieve good low-temperature impact resistance, good wear resistance, and refined ferrite grains effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The high-strength cast steel for the coupler of the railway vehicle of the present invention and its manufacturing method are described in further detail below in conjunction with specific embodiments:

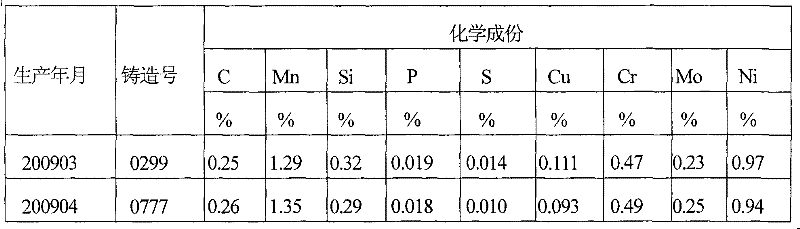

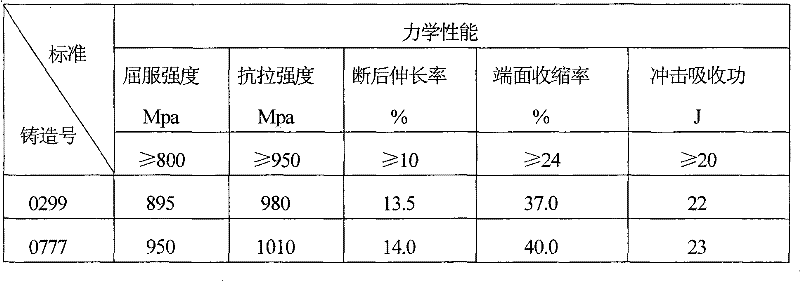

[0020] The high-strength cast steel of the present invention is mainly used to make traction buffer devices for railway vehicles, such as coupler knuckles, coupler tail frames and the like. Taking the coupler knuckle as an example, its chemical composition is calculated by weight percentage as C: 0.22-0.28, Si: 0.20-0.40, Mn: 1.20-1.50, Cr: 0.40-0.60, Ni: 0.90-1.10, Mo: 0.20-0.30 , Al: 0.030~0.080, Cu≤0.30, P≤0.030, S≤0.030, the balance is Fe and unavoidable inclusions.

[0021] The manufacture of the above-mentioned coupler knuckle mainly includes an electric arc furnace smelting process and a casting quenching and tempering heat treatment process. Requirements for harmful impurities in ferroalloy materials in cast steel raw materials: the weight percentage of P and S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com