Portable multifunctional combined temperature tracker and tracking detection method thereof

A detection method and combined technology, applied in the direction of temperature measurement of moving solids, thermometers, thermometers using electrical/magnetic components directly sensitive to heat, etc., can solve the problem of high labor intensity, large heating area of the detector, and large layout space. and other problems, to achieve the effect of long service life of the instrument, reducing the volume of the incubator, and small layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

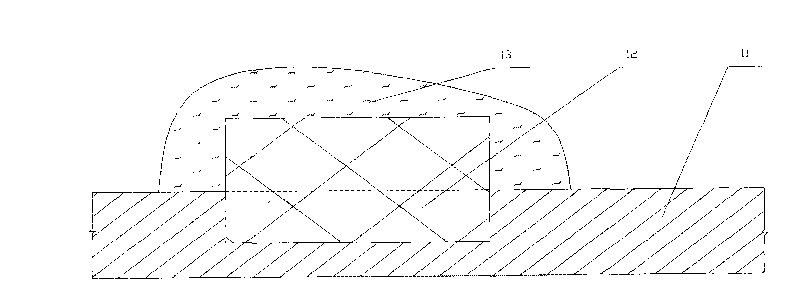

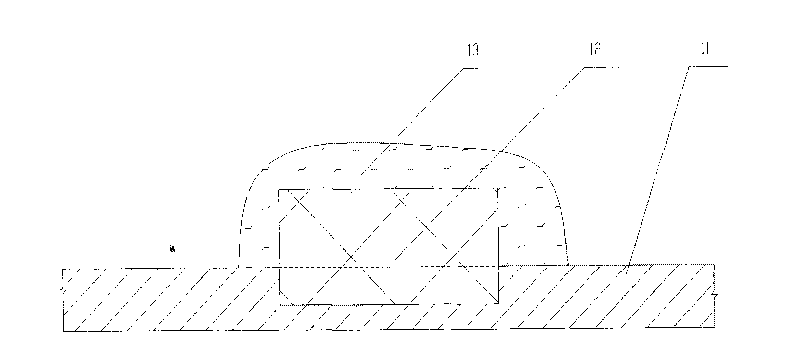

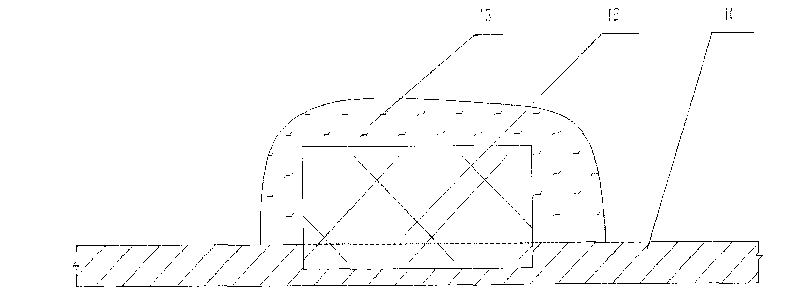

[0031] Such as Figure 4 , 5 , Shown in 6 and 9, a kind of portable multi-functional combined temperature tracker of the present invention, main detector 1 is provided with 14 passages, and auxiliary detector 2 is provided with 8 passages, and each passage is to check separately. The number of channels of the main and auxiliary detectors can be increased or decreased accordingly according to actual needs. The input boards 3 and 4 of the 14-channel main detector 1 are located at both ends of the main detector 1, and the input boards 3 and 4 are provided with bolt-type terminals 5, and the input board 3 is provided with a transfer switch 6, which is suitable for high temperature (950 ~ 1200°C) and ultra-high temperature (1200~1500°C) two-level temperature detection; the input board 7 of the 8-channel auxiliary detector 2 is set at one end, and the input board 7 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com