Winding power inductance component and manufacturing method thereof

A technology of power inductors and manufacturing methods, which is applied in the field of wire-wound power inductors and their manufacturing, can solve the problems of poor resistance to mechanical shock and impact, low frequency of use of devices, and high manufacturing costs, and achieve the improvement of physical shock resistance and the use of The effect of high frequency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

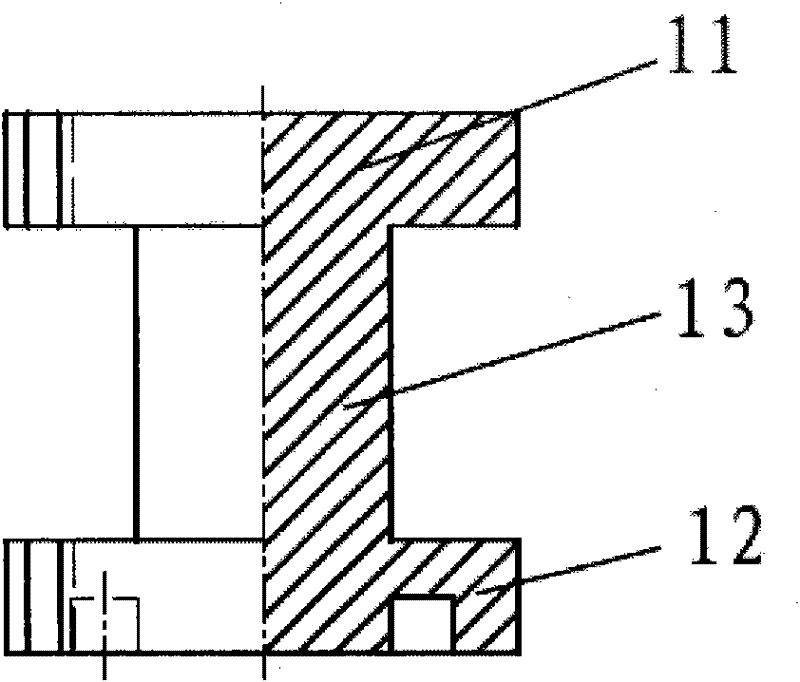

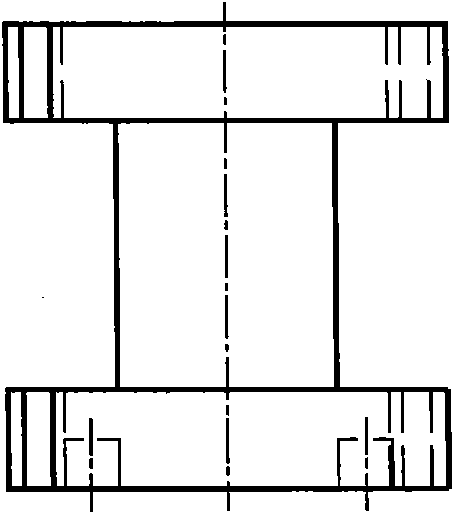

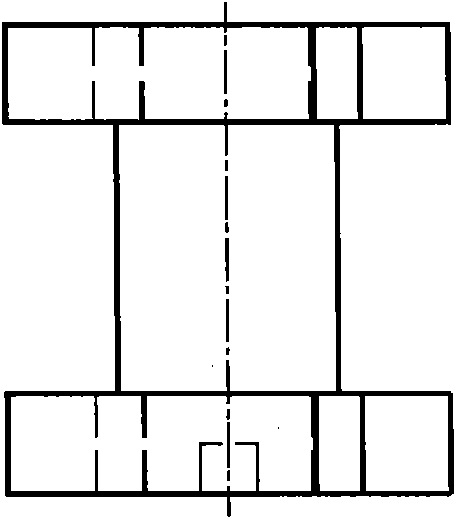

[0042] Please refer to Figure 1 to Figure 4c , a wire-wound power inductive element of an embodiment includes a drum-shaped magnetic core, a coil 31, external electrodes 21a, 21b and a connecting portion 22 connecting the drum-shaped magnetic core and the external electrodes 21a, 21b, and the drum-shaped magnetic core has an upper pendulum 11 , hem 12, and the stem 13 connecting the upper and lower hems, the coil 31 is wound on the stem 13, and the two ends of the coil 31 are electrically connected with the external electrodes 21a, 21b. According to the characteristics of the present invention, the winding power inductive element It also has a magnetic heat-shrinkable material part 41 covering the coil 31 and the upper pendulum 11 and the lower pendulum 12 .

[0043] The magnetic heat-shrinkable material part is a heat-shrinkable elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com