Preparation method of ultra-thin enhanced proton exchange membrane

A proton exchange membrane and enhanced technology, which is applied in the field of preparation of ultra-thin enhanced proton exchange membrane, can solve the problems of low tensile strength, low strength, high price, etc., achieve uniform thickness, increase yield, and improve penetration effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The steps of the preparation method of ultra-thin reinforced proton exchange membrane of the present invention are as follows:

[0030] First, the polytetrafluoroethylene microporous film is pretreated, and the polytetrafluoroethylene microporous film with a thickness of 4 μm, a pore size of 0.9 μm, and a porosity of 70-80% is immersed in a low-carbon alcohol solution for immersion time. 3-4 hours, and then irradiate with ultraviolet rays, the ultraviolet irradiation time is 1.5-2.5 hours, the wavelength of the ultraviolet irradiation is 140-160nm, and the surface temperature of the polytetrafluoroethylene microporous film reaches 55-65°C.

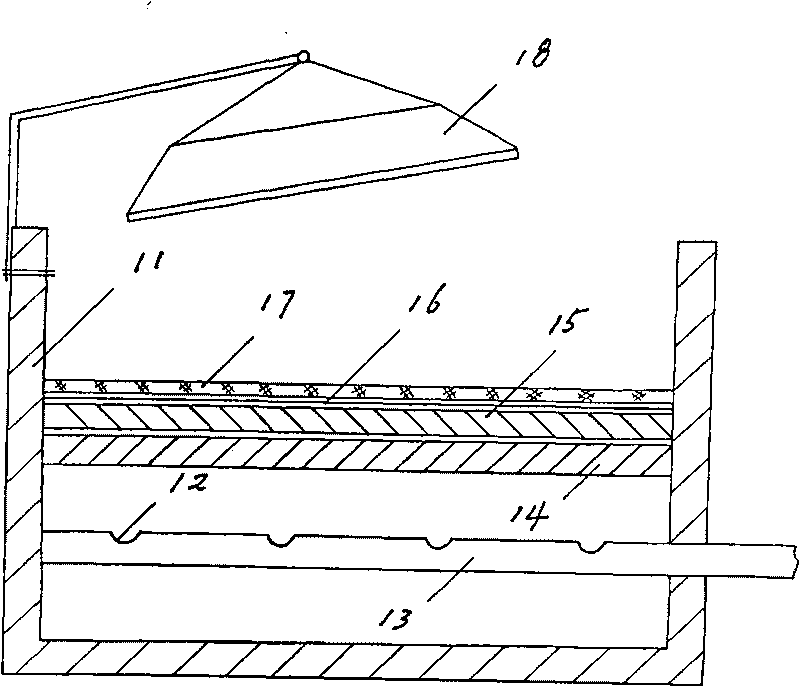

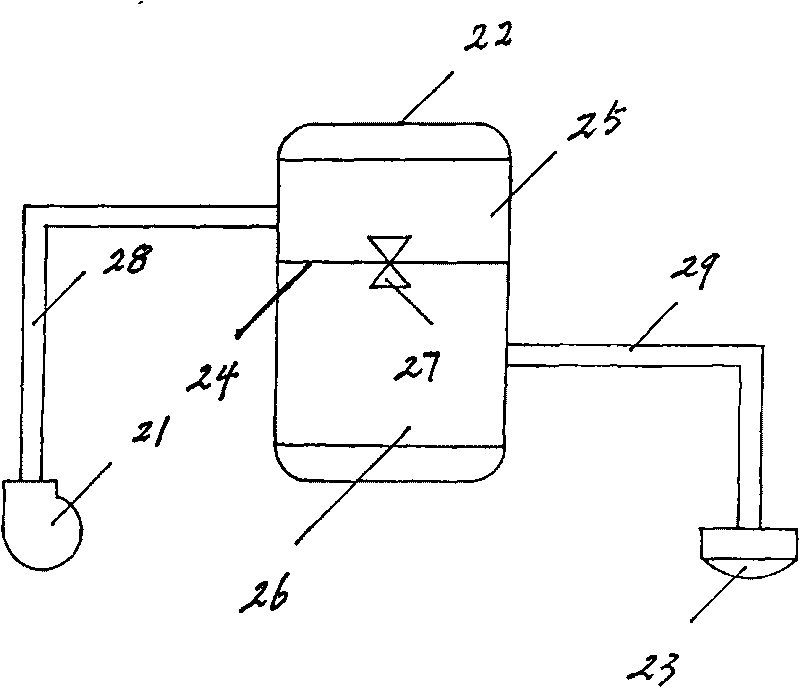

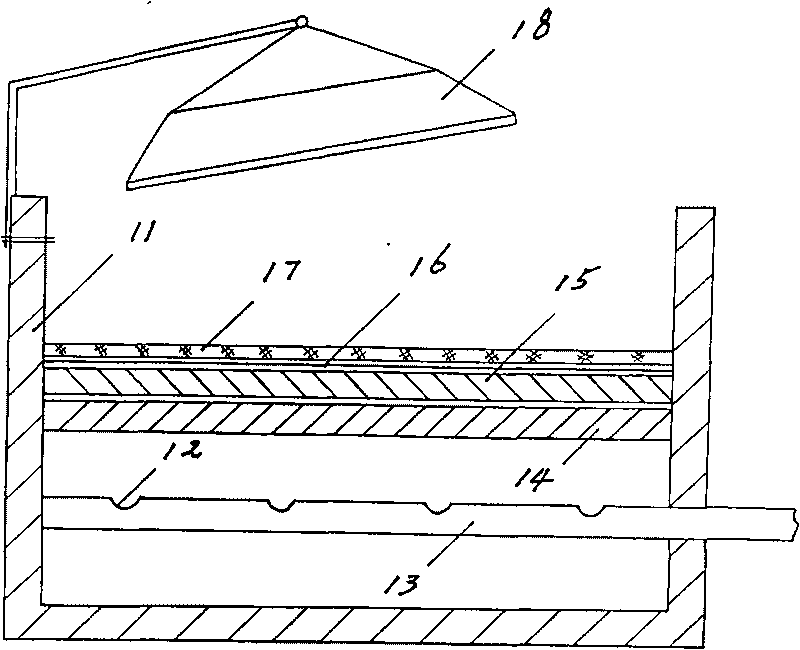

[0031] Then compound, the equipment used during compounding is a reinforced proton exchange membrane compound device and a spray device for spraying sulfonic acid resin solution.

[0032] The enhanced proton exchange membrane composite device includes a composite disc 11, a stainless steel support grid layer 14 arranged in sequence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com