Magnetic field decoupling structure for direct-driven type magnetic suspension linear feed unit

A linear feed and drive type technology, applied in the direction of magnetic attraction or thrust holding device, electrical components, propulsion system, etc., can solve the problems of unmentioned decoupling, decoupling of magnetic field structure, etc., and achieve reasonable structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

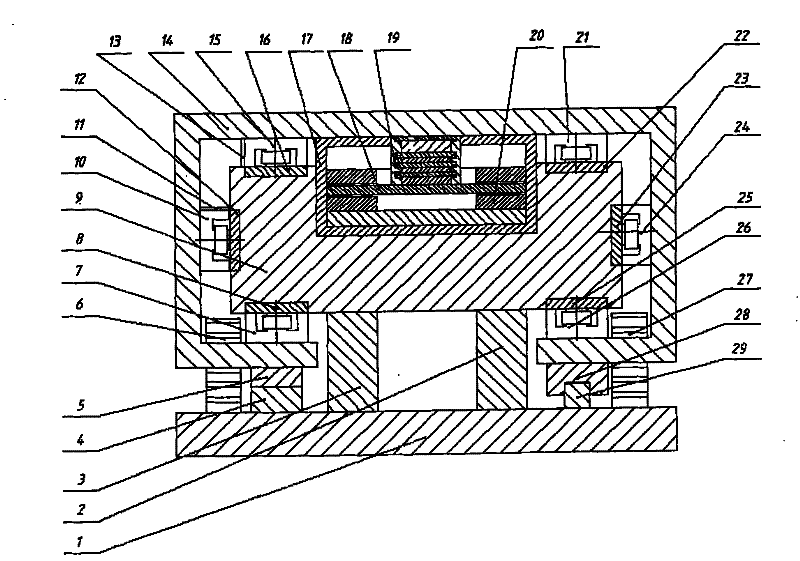

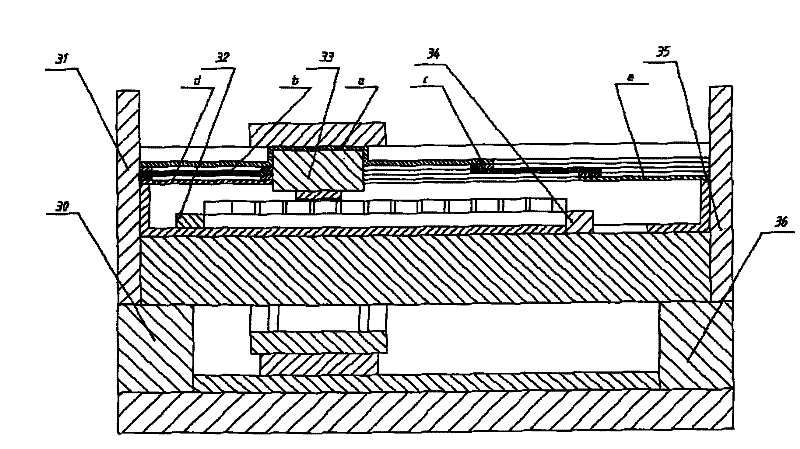

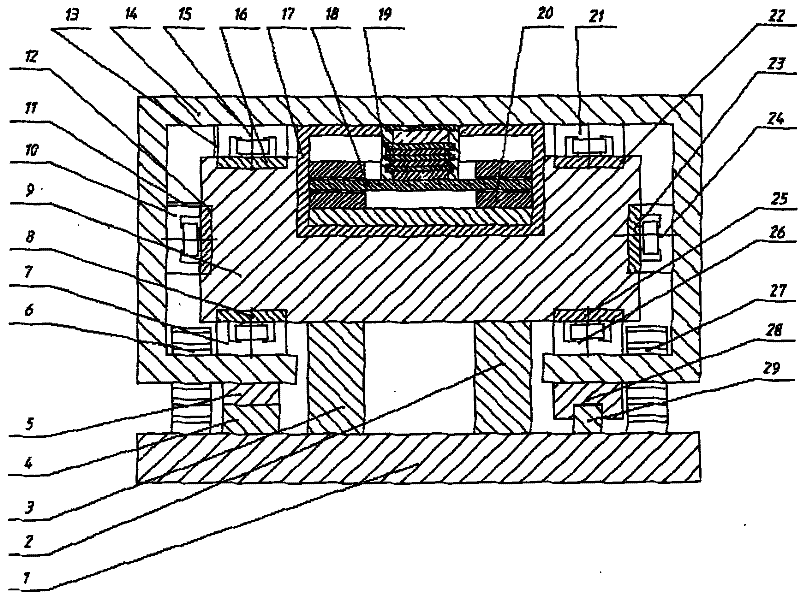

[0021] See attached figure 1 , 2 , a direct drive type magnetic levitation linear feed unit magnetic field decoupling structure, including a base 1, support blocks 2, 3, 30, 36 fixed on the base 1 and two auxiliary support static guide rails 4, 29; installed on the support block 2. The supporting guide rail 9 on 3; the workbench 14 on the outside of the support guide rail, the linear motor stator 20 installed in the center of the support guide rail 9, the mover 18 of the linear motor is installed on the inside of the workbench corresponding to the stator; on the workbench On the inner sides of the upper and lower sides, two pairs of bearing electromagnet groups (including supporting electromagnets 7, 15, 21, 26) arranged up and down are installed, and on the inner sides of the left and right sides of the workbench, there are oppositely arranged guiding electromagnet groups (including guiding electromagnet groups). Electromagnet 10,24), support guide rail comprises the main pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com