Nanometer iron powder special for shielding electromagnetic wave and radar wave in glass cockpit of airplane

A nano-iron powder, radar wave technology, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problem of incomplete shielding effect of nano-metal powder for radar waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

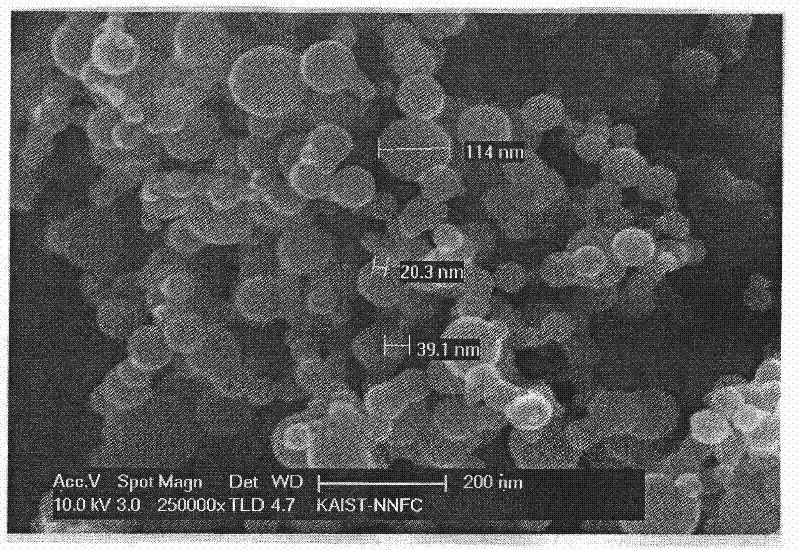

Embodiment 1

[0017] Example 1, a special nano-iron powder for electromagnetic and radar wave shielding in the glass cockpit of an aircraft is made by the following method. In the case of -5°C, the frequency of high-frequency cutting is set at 6000 times per minute. Production, Nano-iron powder with special stealth technology for processing powder particles in the form of spheres. Then use the "cyclone classification process" to sort out (25nm as an example) powder materials with concentrated particle distribution of D3=21nm D25=22.1nm D50=25nm D75=27.2nmD97=30.3nm, and then use the "DQ coating method "Continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

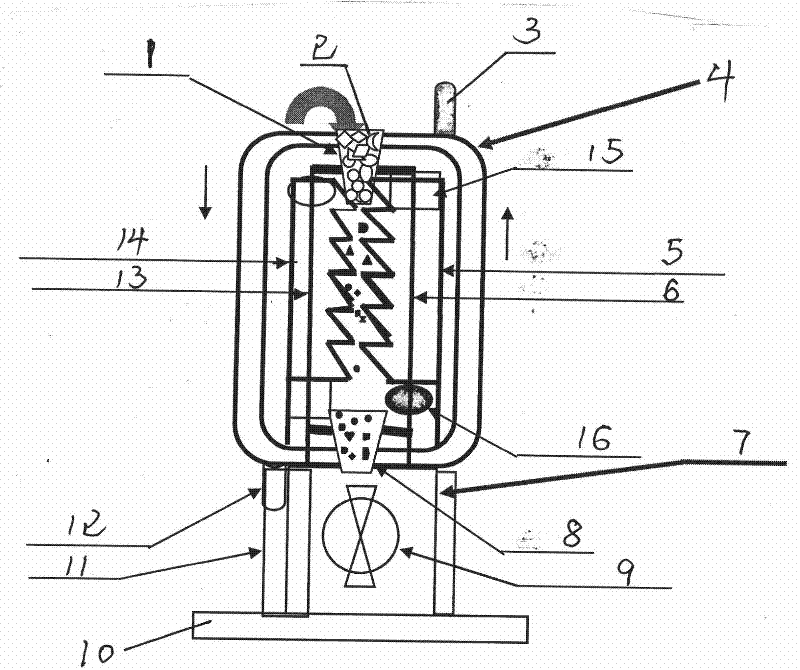

[0018] The cutting machine used is as figure 1 As shown, the cutting machine structure includes a body 4 with a cooling system. The body 4 is provided with a feed port 2 and an inert gas inlet 1. In the body 4 (the lower end of the feed por...

Embodiment 2

[0024] Example 2, a special nano-iron powder for electromagnetic and radar wave shielding in the glass cockpit of an aircraft is made by the following method. It is produced and processed under the condition of 0°C and the frequency of high-frequency cutting is set at 5500 times per minute. The shape of the powder particles is a spherical nano-iron powder with special stealth technology. Then use the "cyclone classification process" to sort out (25nm as an example) powder materials with concentrated particle distribution of D3=21nm D25=22.1nm D50=25nm D75=27.2nmD97=30.3nm, and then use the "DQ coating method "Continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

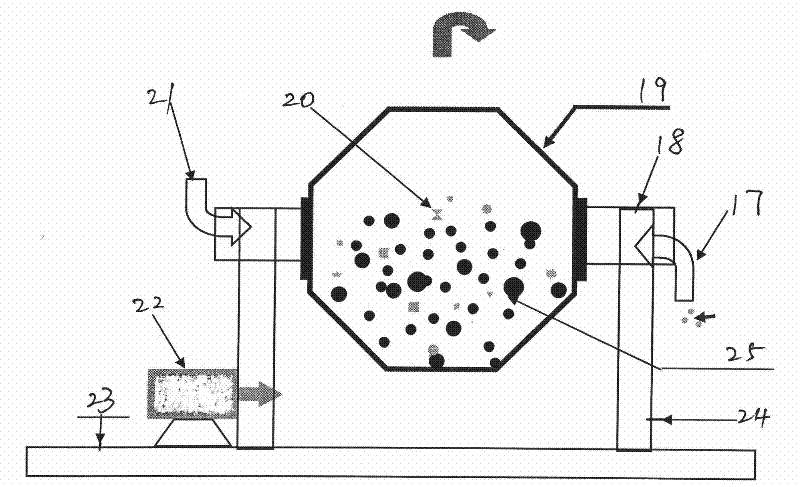

[0025] According to the characteristics of stealth technology, the coated powder material is input into a high-speed grinder for surface treatment of powder particles, so that the surface of the powder particle material ...

Embodiment 3

[0027] Embodiment 3, a special nano-iron powder for electromagnetic and radar wave shielding in the glass cockpit of an aircraft is made by the following method. Under the condition of -3°C, the frequency of high-frequency cutting is set at 5750 times per minute. Nano-iron powder with special stealth technology for processing powder particles in the form of spheres. Then use the "cyclone classification process" to sort out (25nm as an example) powder materials with concentrated particle distribution of D3=21nm D25=22.1nm D50=25nm D75=27.2nmD97=30.3nm, and then use the "DQ coating method "Continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0028] According to the characteristics of stealth technology, the coated powder material is input into a high-speed grinder for surface treatment of powder particles, so that the surface of the powder particle material is smooth and the sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com