Processing and testing integrated complex numerical control machine tool

A CNC machine tool and composite technology, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that CNC machine tools cannot realize on-machine inspection, and achieve the effect of saving costs and improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

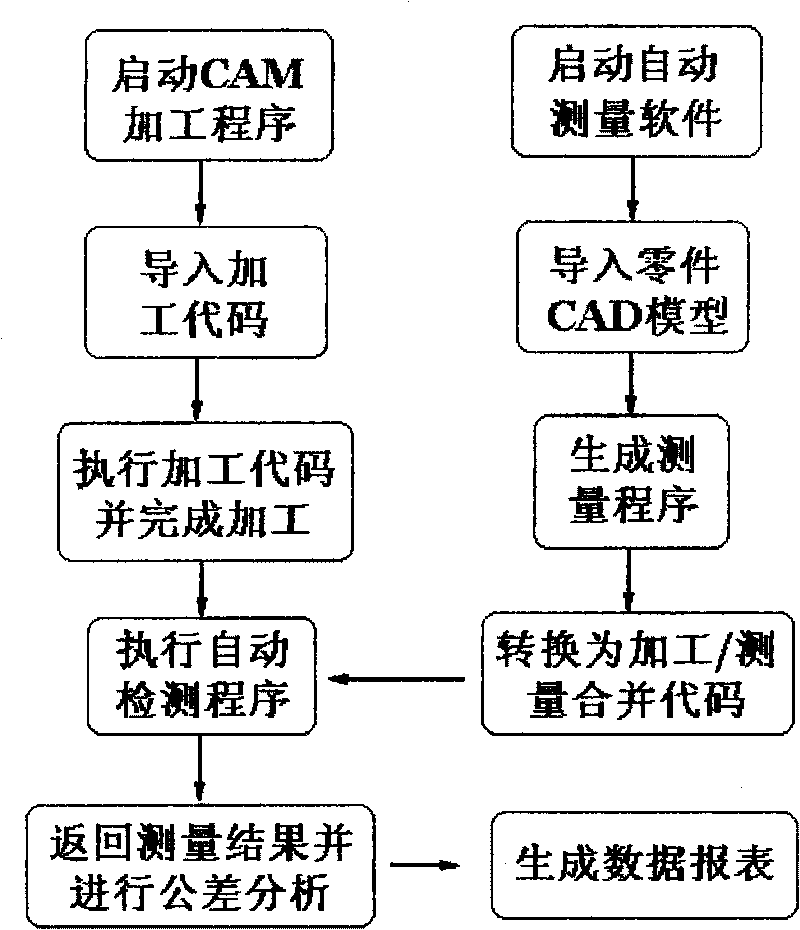

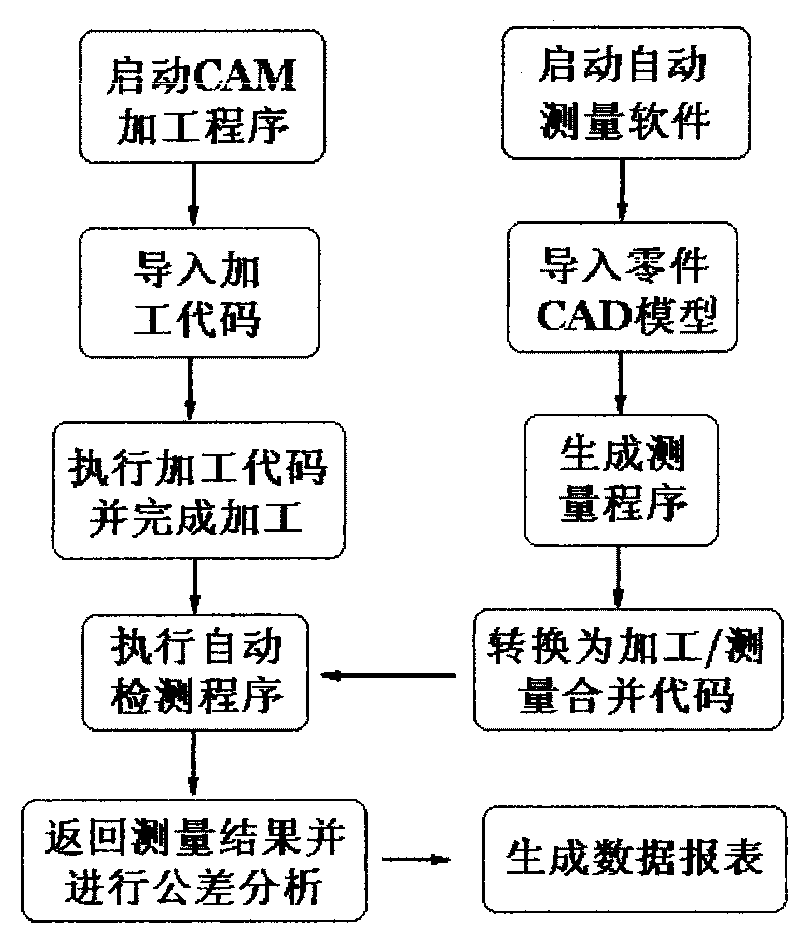

[0008] For the implementation of the working principle and structure of the present invention and the processing / detection integrated compound numerical control machine tool, the following examples are taken of milling / detection and turning / detection and combined figure 1 To elaborate:

[0009] 1. Turning / detection compound CNC machine tool: The main components of the current CNC lathe are the spindle system, feed system and control system, etc. The reason why the CNC lathe can realize CNC mainly depends on digital motion control and position feedback. However, as a processing machine tool, the accuracy of its position feedback system obviously cannot meet the requirements of the measuring equipment. Therefore, in the present invention, the feedback system must first be improved to meet the requirements of the testing equipment, and the entire feed system and spindle system can be formed. Full-closed-loop movement to meet detection requirements.

[0010] Since the measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com