Mass flow meter and mass flow controller

一种质量流量计、流量计算的技术,应用在流量传感器领域,能够解决流量测量精度降低、测量流量误差、测量流量的误差不同等问题,达到减小误差、提高流量测量精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

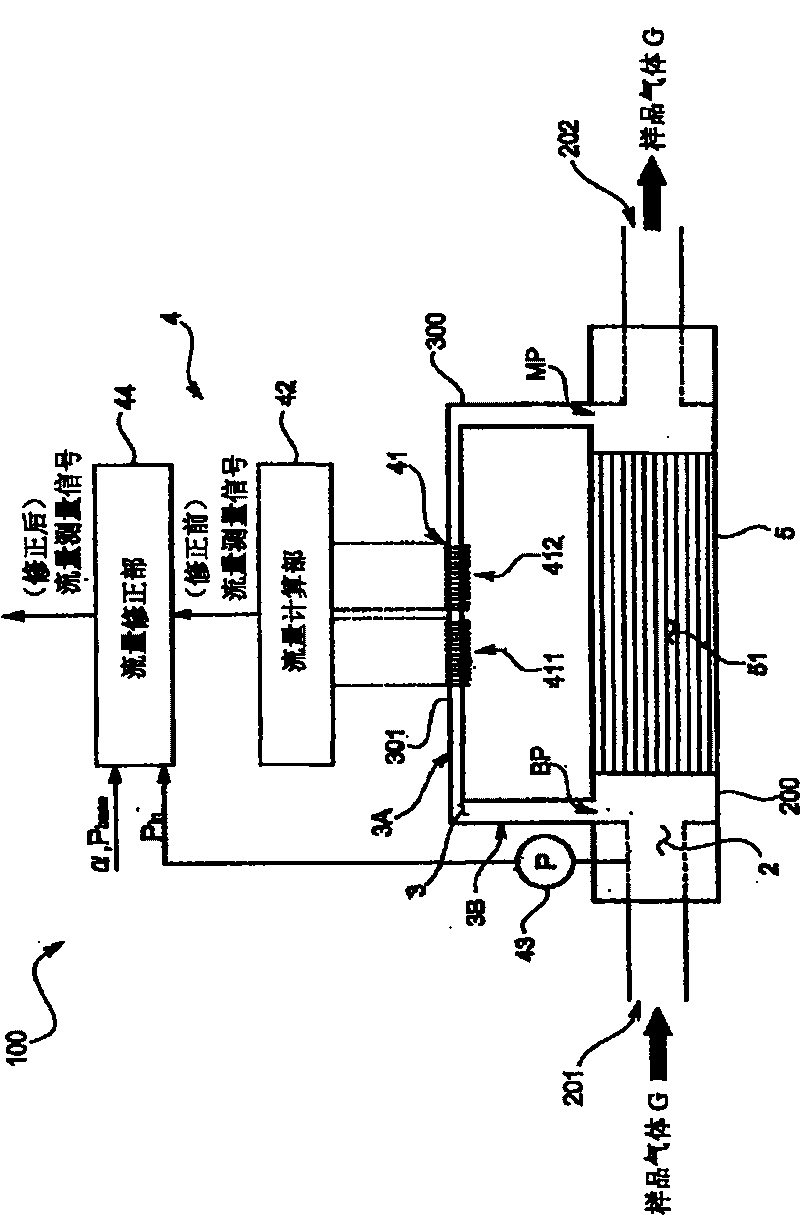

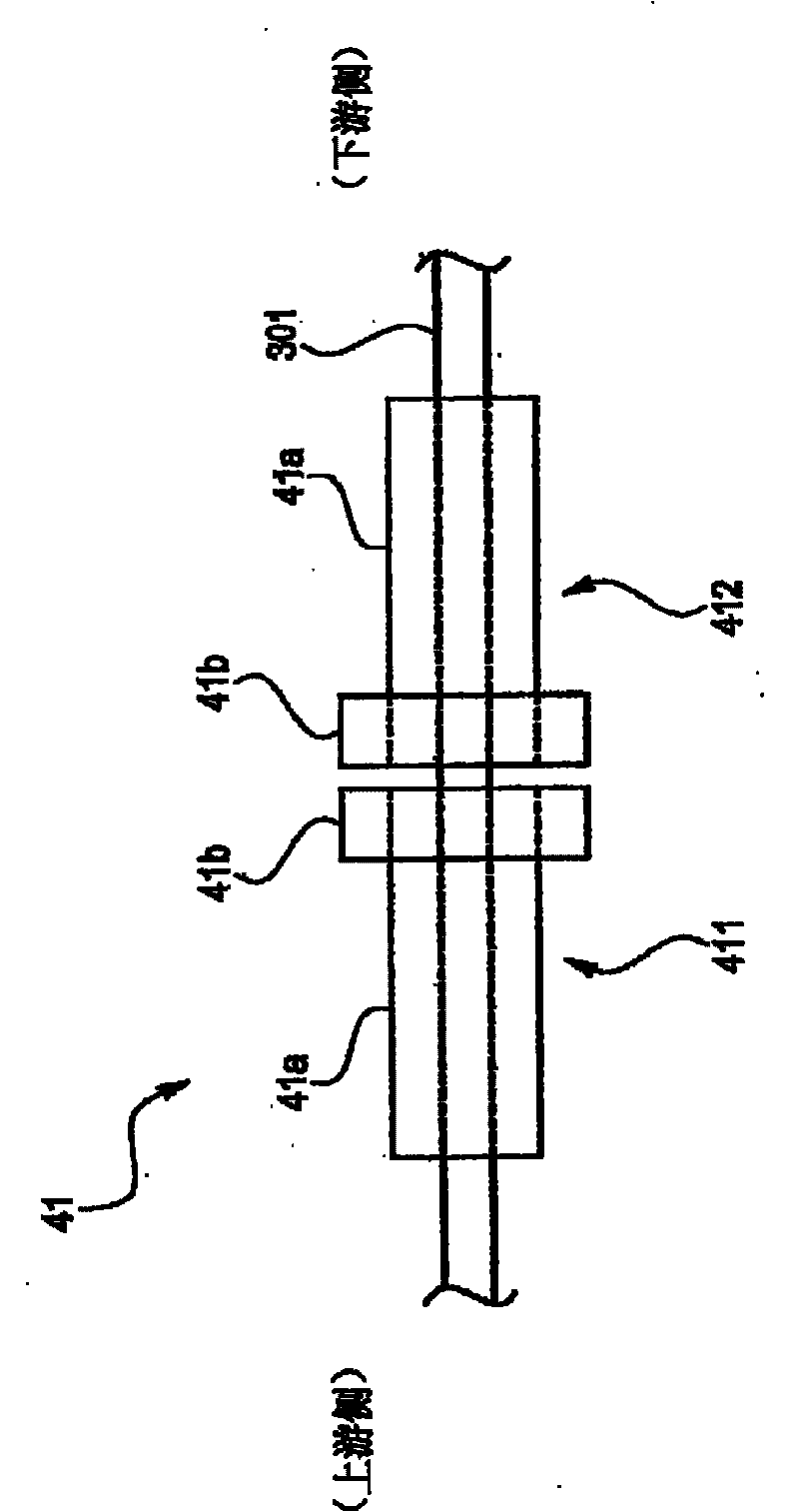

[0054] A first embodiment of the mass flow meter 100 of the present invention will be described below with reference to the drawings. in addition, figure 1 It is a schematic diagram showing the configuration of the mass flowmeter 100 of this embodiment.

[0055]

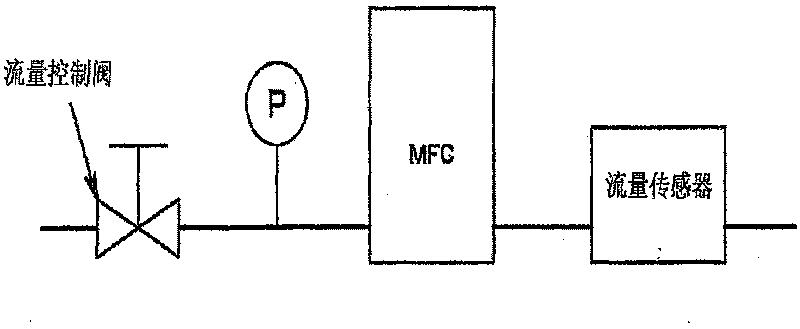

[0056] The mass flowmeter 100 of this embodiment is a thermal mass flowmeter, including: a sample gas (such as SF 6 The main flow path 2 through which the semiconductor processing gas such as) G flows; the sensor flow path 3 is branched from the main flow path 2 to split the sample gas G, and the flow rate Q of the sample gas G raw To detect; the flow detection mechanism 4, the flow Q of the sample gas G raw detection; and a laminar flow element 5 disposed between the branch point BP and the confluence point MP of the sensor flow path 3 in the main flow path 2 and having a plurality of internal flow paths 51 .

[0057] Hereinafter, each part 2-5 is demonstrated.

[0058] The main passage 2 is formed by a substant...

no. 2 approach

[0084] Next, a second embodiment of the mass flowmeter 100 of the present invention will be described. The mass flow meter 100 of this embodiment is as Figure 5 As mentioned above, it further includes a function data storage unit D1, and the function of the flow correction unit 44 is different from that of the flow correction unit 44 in the first embodiment.

[0085] The function data storage unit D1 stores the relational data, the relational data is the reference pressure P base In the following approximate formula (2) obtained by approximating the error [%] between the flow rates with a predetermined function (a linear formula in this embodiment), coefficient a (slope (slope) a) and coefficient b ( Relational expression of intercept b) relative to gas physical property value. This relational expression data is previously input by a user or the like through an input unit.

[0086] [mathematical formula 4]

[0087] Error[%]=a×Q raw +b...(2)

[0088] However, the slope a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com