Center shaft type electromobile motor

An electric vehicle, shaft-type technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of insufficient assembly structure, limited power supply mileage, high energy consumption of electric power supply, etc., to achieve volume reduction and continuous mileage extension , The effect of reducing electric energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

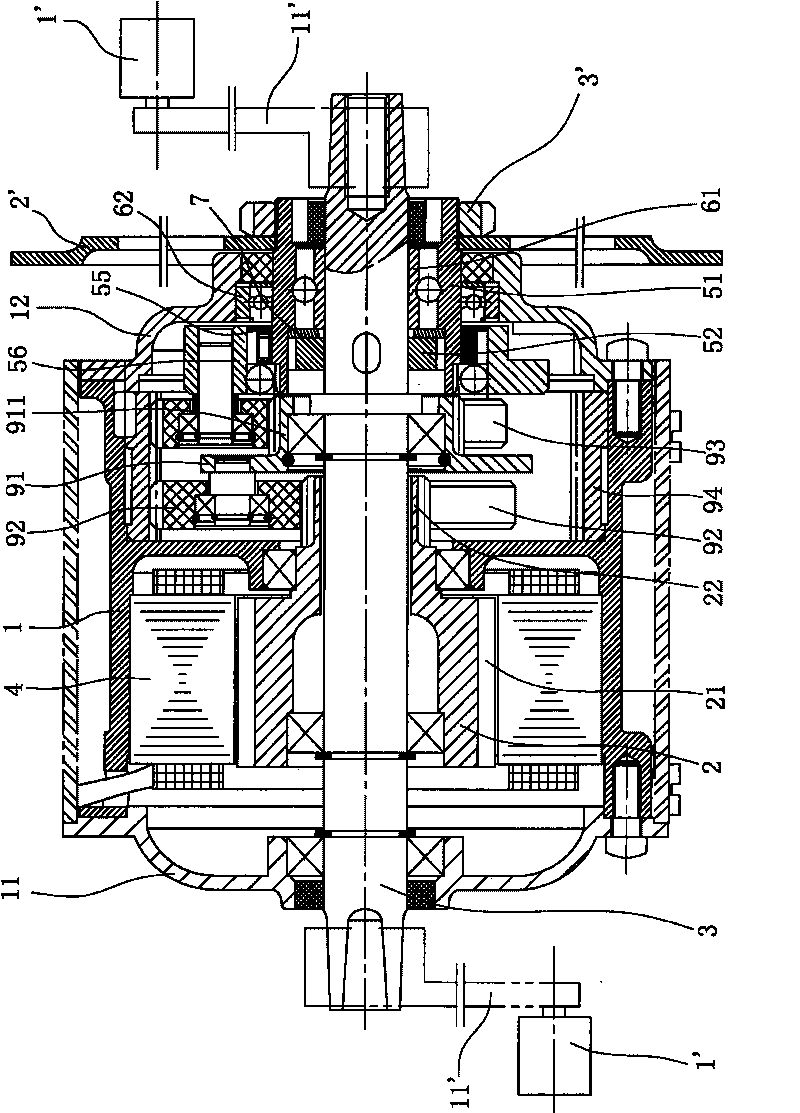

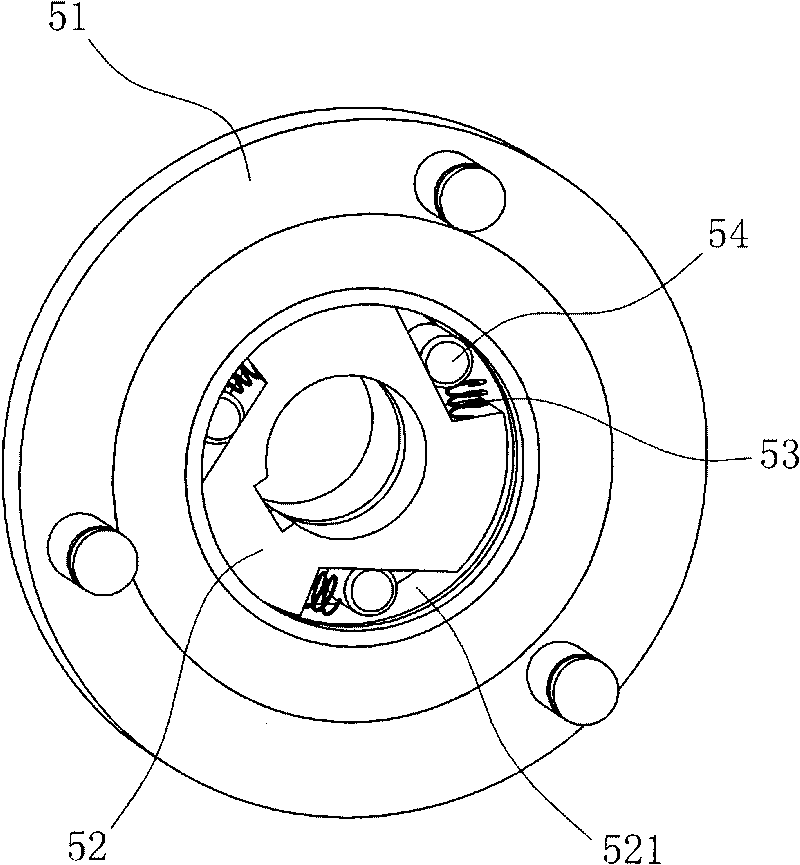

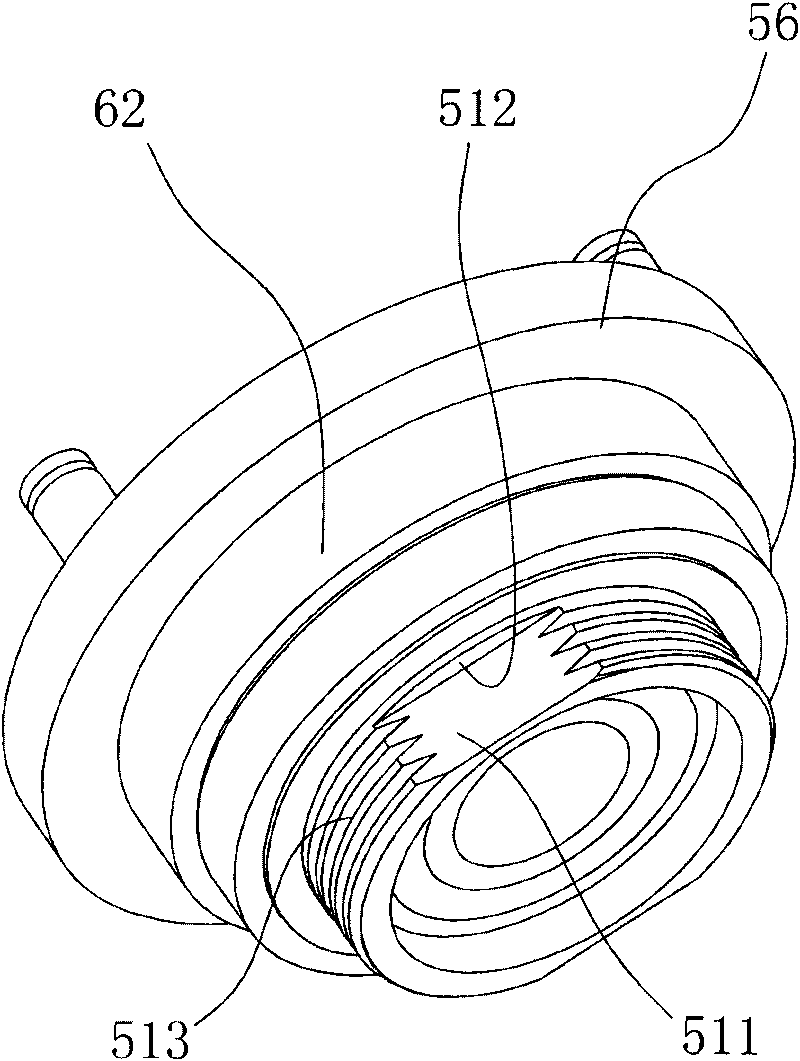

[0025] Such as Figure 1 to Figure 6 As shown, it is a schematic diagram of the structure of the electric vehicle motor in this embodiment. The electric vehicle motor uses the central shaft 3 of the electric vehicle as the motor shaft, and is a high-speed brushless motor with an inner rotor structure, which can realize machine embedding when the motor is mass-produced. Suitable for mass production; Among them, electric vehicle motors include

[0026] The casing 1 is provided with a front end cover 11 and a rear end cover 12 forming a closed cavity with the casing 1 at both ends of the casing 1 .

[0027] The rotor 2 is rotatably arranged on the central shaft 3 of the electric vehicle and is positioned by bearings. The two ends of the central shaft 3 are also fixedly connected with pedals 1' for human pedaling through cranks 11'.

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com