Power generation and hydrogen production combined circulating system based on alkali metal thermoelectric conversion

A thermoelectric conversion and circulation system technology, applied in the direction of generators, non-metallic elements, generators/motors, etc. that convert kinetic energy into electrical energy, can solve problems such as large investment, achieve high power density, no maintenance, and high thermoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

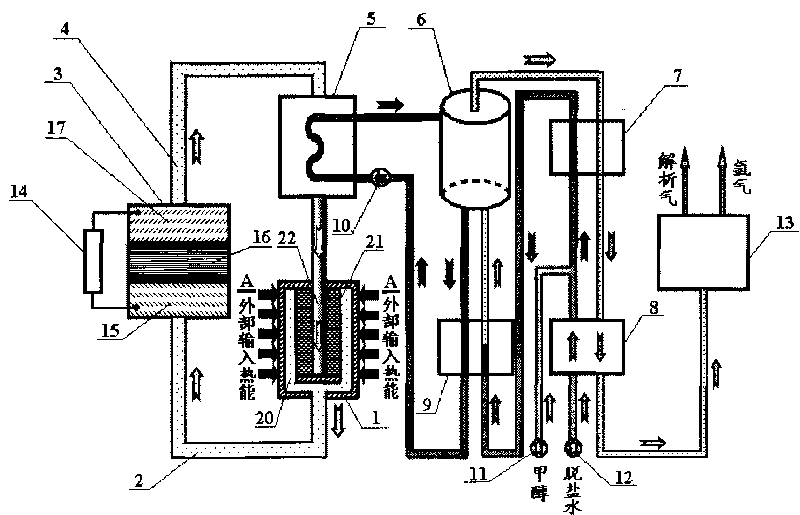

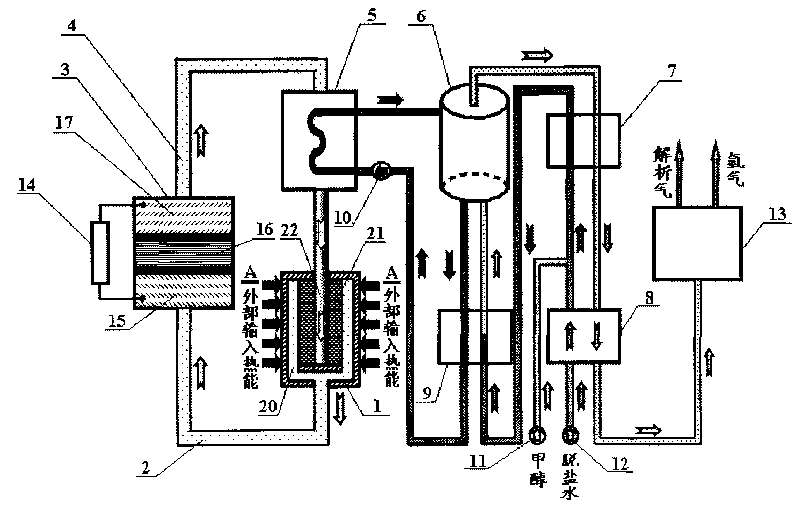

[0014] The following in conjunction with the accompanying drawings in the description figure 1 , figure 2 The specific implementation of the present invention will be described in detail.

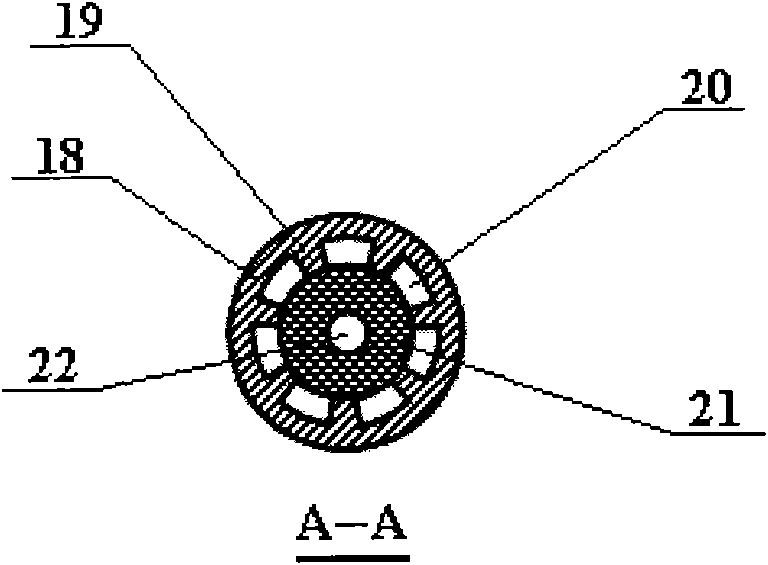

[0015] The present invention mainly consists of an evaporator 1, a high-pressure sodium steam pipeline 2, an alkali metal thermoelectric converter 3, a low-pressure sodium steam pipeline 4, a condenser 5, a reactor 6, a preheater 7, a condensation absorber 8, a vaporization superheater 9, It consists of a heat conduction oil pump 10, a methanol pump 11, a desalted water pump 12, a pressure swing adsorption separation device 13 and connecting pipelines. Wherein, evaporator 1 is made up of shell 18, vertical straight fin 19, sodium vapor channel 20, porous capillary core 21 and sodium liquid channel 22; Alkali metal thermoelectric converter 3 is made up of load 14, porous film anode 15, β " It consists of aluminum solid electrolyte 16 and porous film cathode 17.

[0016] Working process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com