Method for processing camshaft spline of automotive brake and device therefor

A processing equipment and camshaft technology, which is applied in metal processing equipment, manufacturing tools, metal extrusion forming tools, etc., can solve the problems of large spline angle deviation, obvious burrs at cutting places, and serious scale-like tool marks, etc. Achieve the effect of consistent spline tooth shape, enhanced surface compactness and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

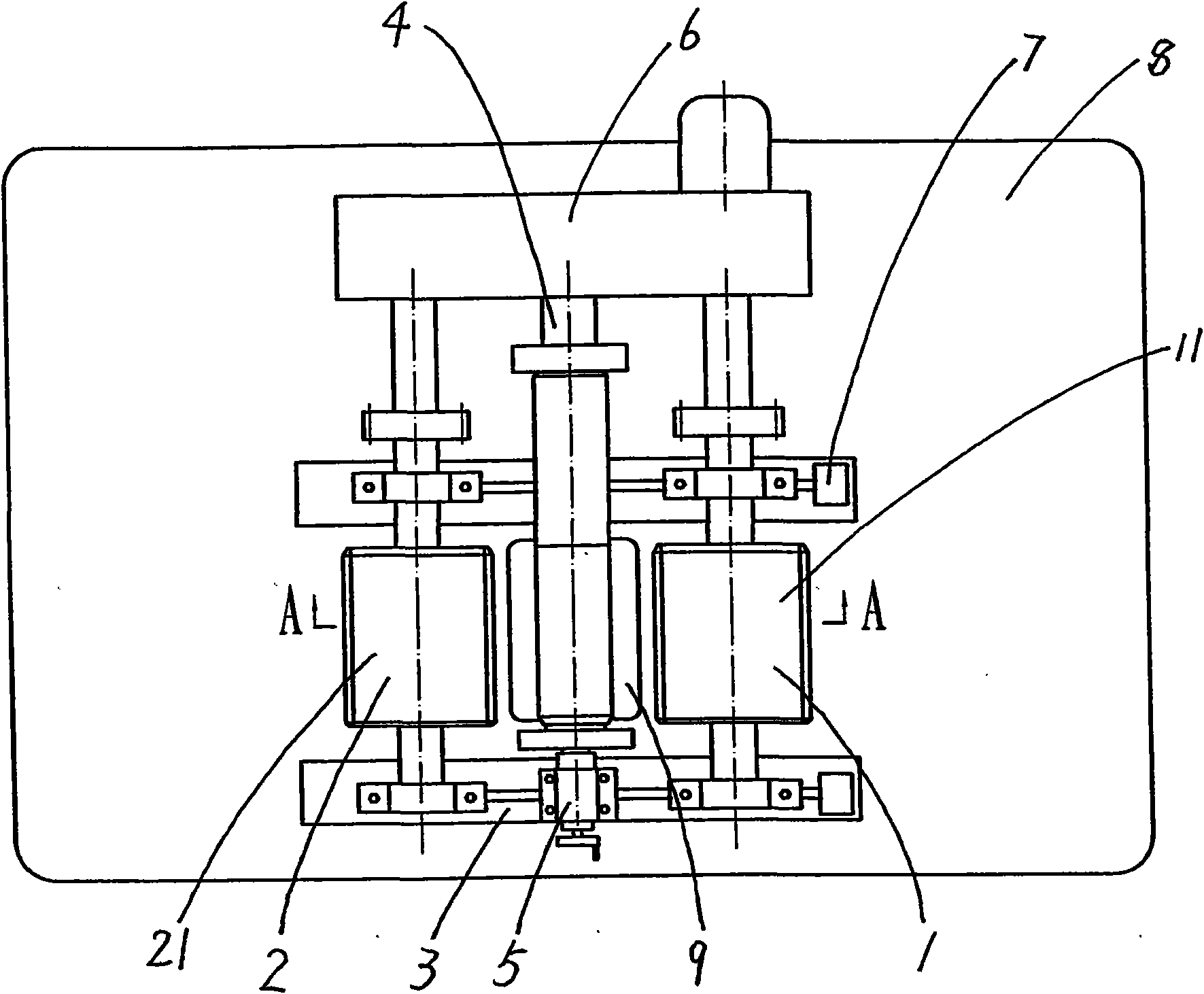

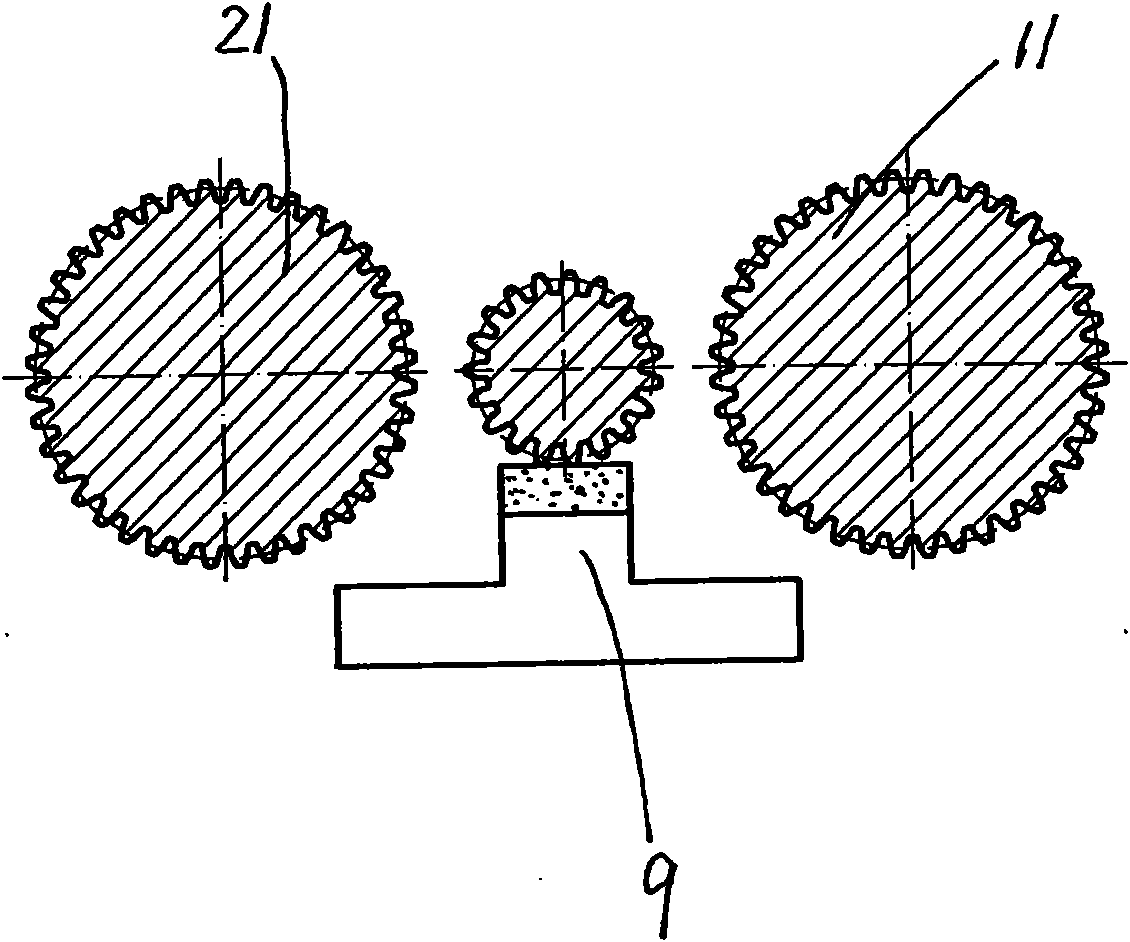

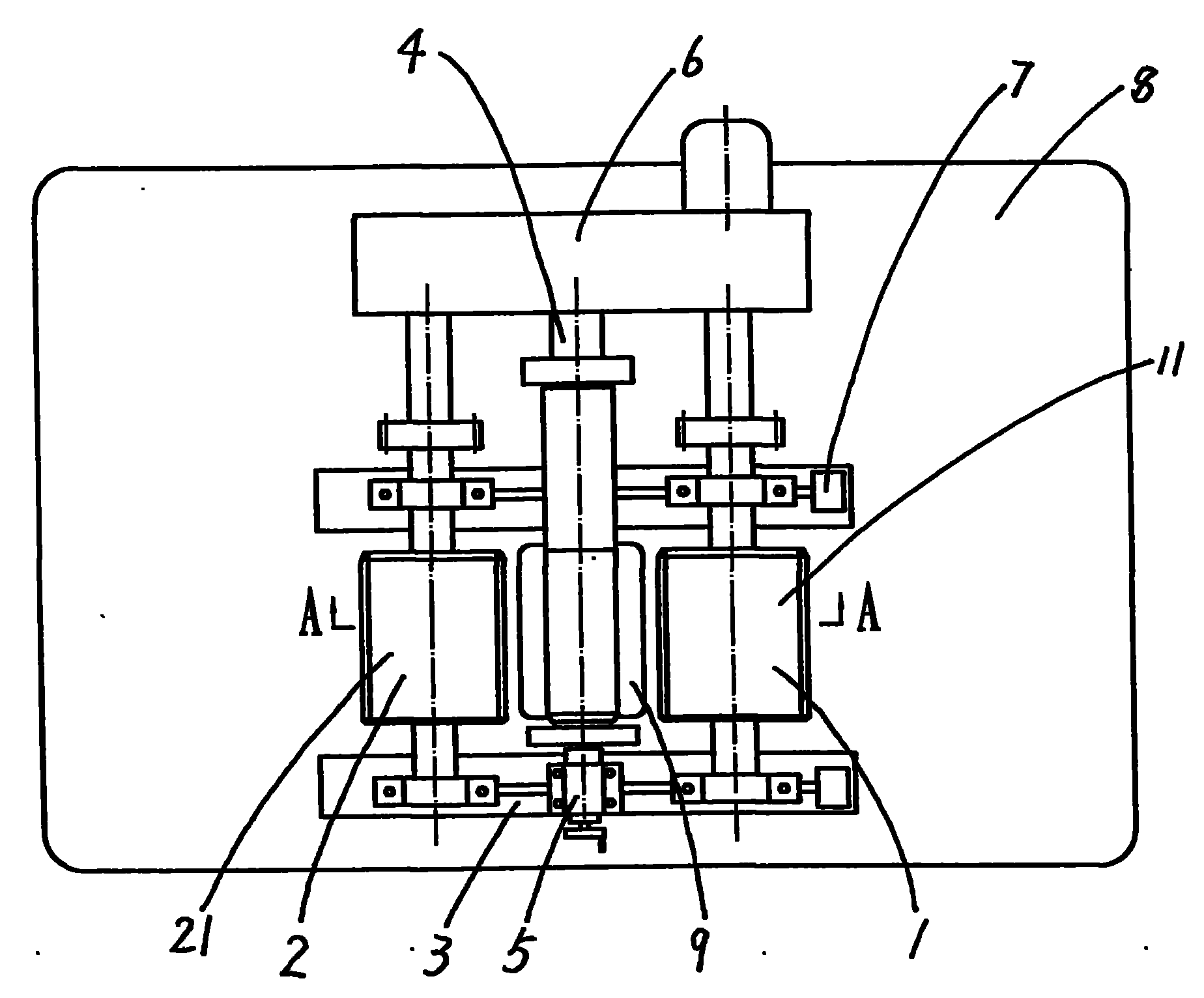

[0024] Refer to attached figure 1 , attached figure 2 , a kind of processing method of automobile brake camshaft spline of the present invention, comprises the following steps:

[0025] (1) Machine the shaft end of the spline shaft to be processed to the reserved size;

[0026] (2) Heating the part of the workpiece to be processed to 250°C to 300°C, which is 280°C in this embodiment;

[0027] (3) Install the heated workpiece to be processed on the wear-resistant support;

[0028] (4) Tighten the spline shaft to be processed through the adjustment device;

[0029] (5) Adjust the extrusion roller spacing;

[0030] (6) Start the equipment, and under the drive of the extrusion roller position adjustment mechanism, the two extrusion rollers gradually approach the spline shaft to be processed for extrusion;

[0031] (7) Under the rolling of the two extrusion rollers, the spline shaft is extruded to the required spline size to obtain the finished product.

[0032] A processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com