Plasma remelting system and process for thermal spraying of superfine powder

A technology of ultra-fine powder and plasma, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of easy decarburization of carbide powder, change of powder composition, change of powder particle size, etc., and achieve the best performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

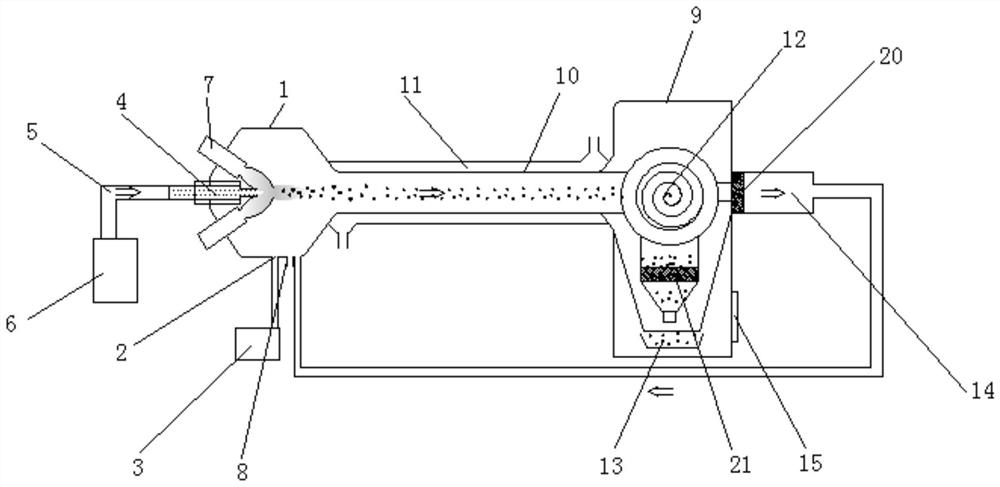

[0032] Embodiment 1: as figure 1As shown, a plasma remelting system for thermal spraying ultrafine powder includes a high-pressure chamber 1 in the remelting zone. The high-pressure chamber 1 in the remelting zone is provided with a vacuum port 2, and the vacuum port 2 communicates with the vacuum device 3. The high-pressure chamber 1 in the remelting zone is also provided with a feeding nozzle 4, and the feeding nozzle 4 is connected to the powder feeder 6 through the powder feeding pipe 5; the high-pressure chamber 1 in the remelting zone is also provided with more than two plasma torches 7, The plasma torch 7 and the high-pressure chamber 1 in the remelting zone are connected by a universal adjustment head, and the ejection outlet of the plasma torch 7 converges to the front end of the ejection outlet of the feeding nozzle 4; the high-pressure chamber 1 in the remelting zone is equipped with an inert The gas inlet 8, the high-pressure chamber 1 in the remelting zone are pro...

Embodiment 2

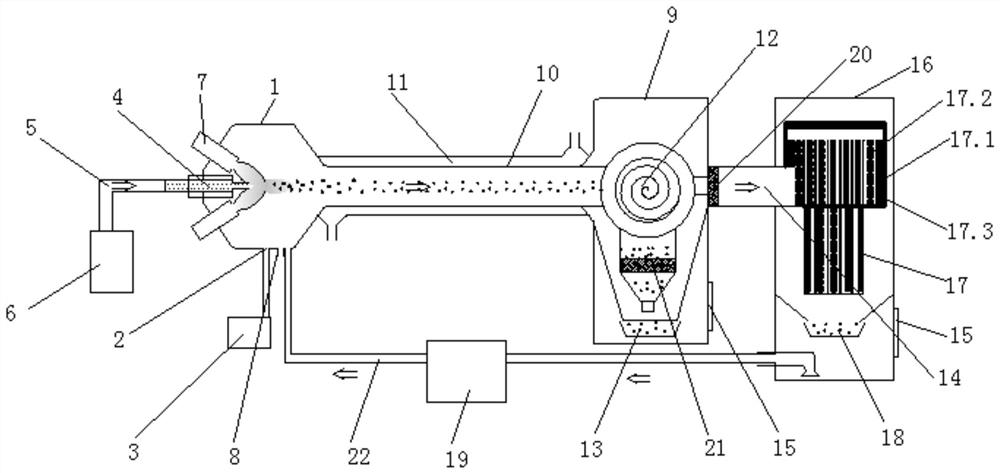

[0033] Embodiment 2: as figure 2 As shown, a plasma remelting system for thermal spraying ultrafine powder includes a high-pressure chamber 1 in the remelting zone. The high-pressure chamber 1 in the remelting zone is provided with a vacuum port 2, and the vacuum port 2 communicates with the vacuum device 3. The high-pressure chamber 1 in the remelting zone is also provided with a feeding nozzle 4, and the feeding nozzle 4 is connected to the powder feeder 6 through the powder feeding pipe 5; the high-pressure chamber 1 in the remelting zone is also provided with more than two plasma torches 7, The plasma torch 7 and the high-pressure chamber 1 in the remelting zone are connected by a universal adjustment head, and the ejection outlet of the plasma torch 7 converges to the front end of the ejection outlet of the feeding nozzle 4; the high-pressure chamber 1 in the remelting zone is equipped with an inert The gas inlet 8, the high-pressure chamber 1 in the remelting zone are p...

Embodiment 3

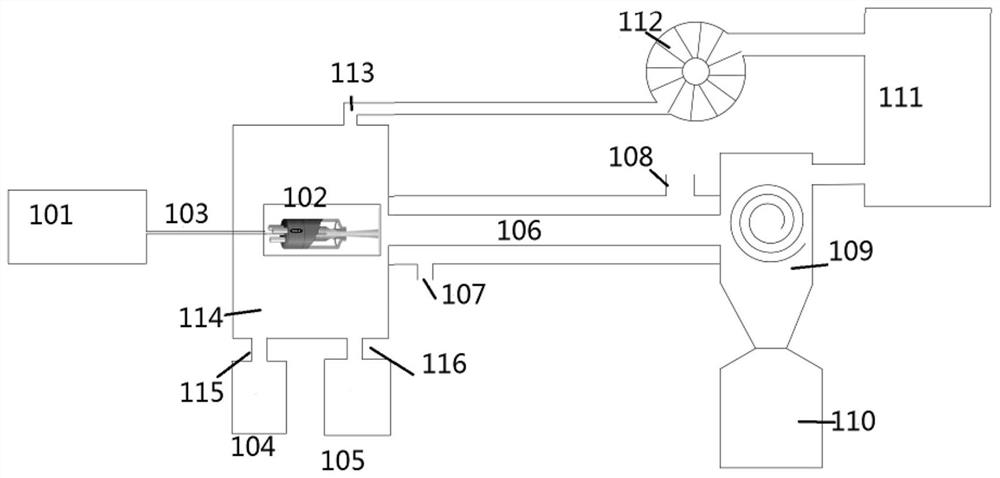

[0035] Embodiment 3: as image 3 , 4 As shown, 101 is a powder feeder, 102 is a plasma spray gun for thermal spraying, and 101 and 102 are connected through a powder feeding pipe 103 . 114 is a chamber, 104 is a vacuum device, connected with the chamber 114 through a valved pipeline 115, and 105 is a protective gas (such as nitrogen) bottle, connected with the chamber 114 through a valved pipeline 116; 106 is a cooling pipeline, on which Cooling water inlet 107 and water outlet 108 are provided; cyclone separator 109 is connected with cooling pipeline 106; cyclone separator 109 is connected with powder collector 110; air filter system 111 is connected with cyclone separator 109; fan 112 is connected with air filter system 111 is connected; fan 112 is connected with chamber 114 through pipeline 113 .

[0036] When working: the cooling water inlet 107 is fed with cooling water, the vacuum device 104 is turned on to pre-evacuate the inside of the plasma remelting spheroidizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com