Horizontal multi-helix biomass continuous hydrolysis and saccharification device and method

A multi-helix, biomass technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as low productivity and high labor intensity, and achieve improved production efficiency and accurate control The effect of reaction time, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

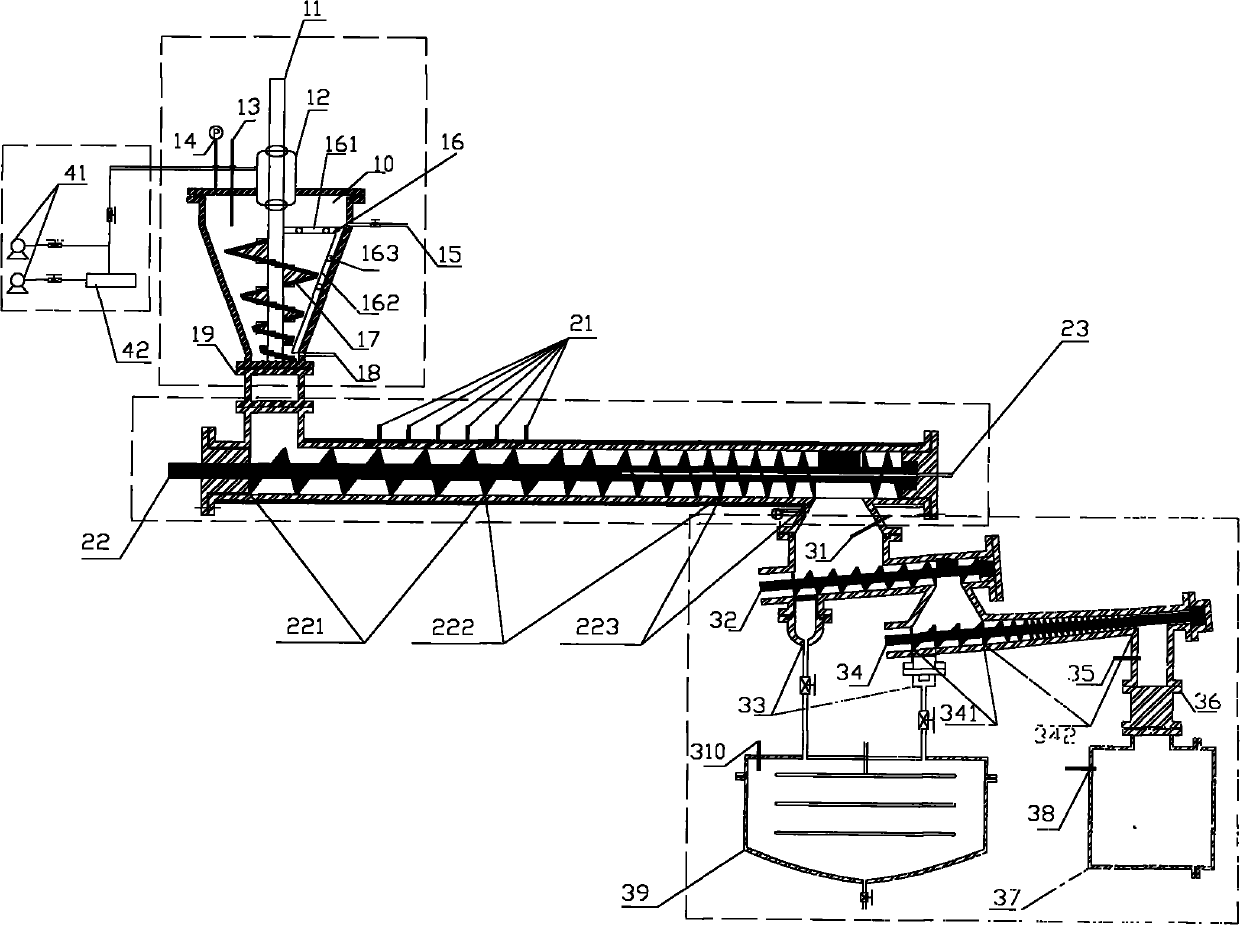

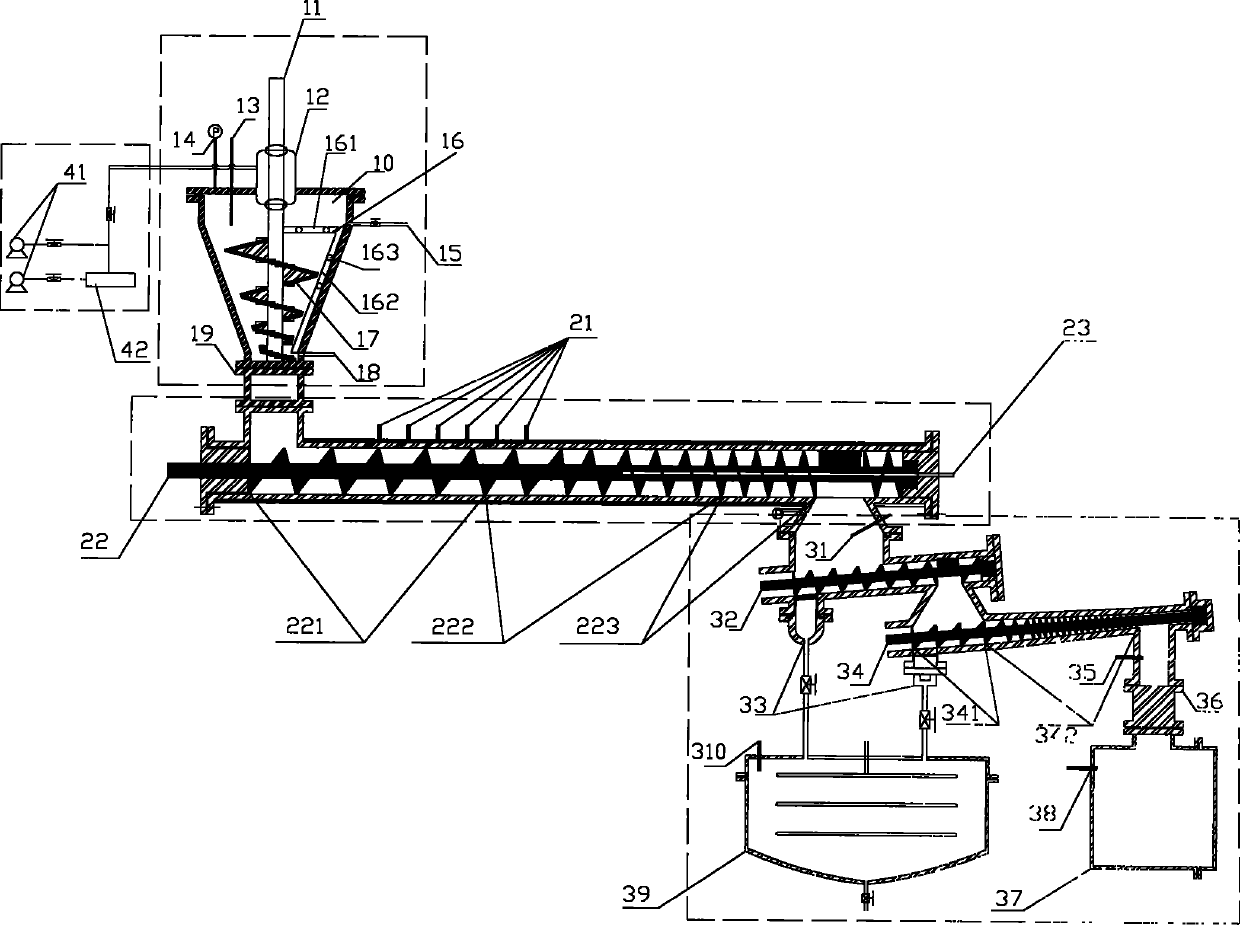

[0033] see figure 1 As shown, the horizontal multi-helix biomass continuous hydrolysis and saccharification device includes a raw material storage and delivery system 1 for storing and transporting the reaction raw materials, and the output end of the raw material storage and delivery system 1 is connected to a solid and liquid reaction raw material for fully stirring and compressing The main reaction section 2 of the main reaction section is connected with a heat supply system 4 for adjusting the reaction temperature at the input end of the raw material storage and delivery system 1, and is connected with a post-reaction treatment system 3 for separating solid materials and liquid materials at the output end of the main reaction section 2 .

[0034] The biomass raw material is continuously transported into the reaction system after the first step of pretreatment in the raw material storage and transportation system 1, and the hydrolysis reaction is carried out under the propu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com