Method for segmented acid-adding and circulating leaching of coarse particles in laterite nickel ores

A technology of laterite nickel ore and acid circulation is applied in the field of metal metallurgy, which can solve the problems of high cost and low leaching rate of nickel and cobalt, and achieve the effects of improving strength, being beneficial to leaching and improving penetration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

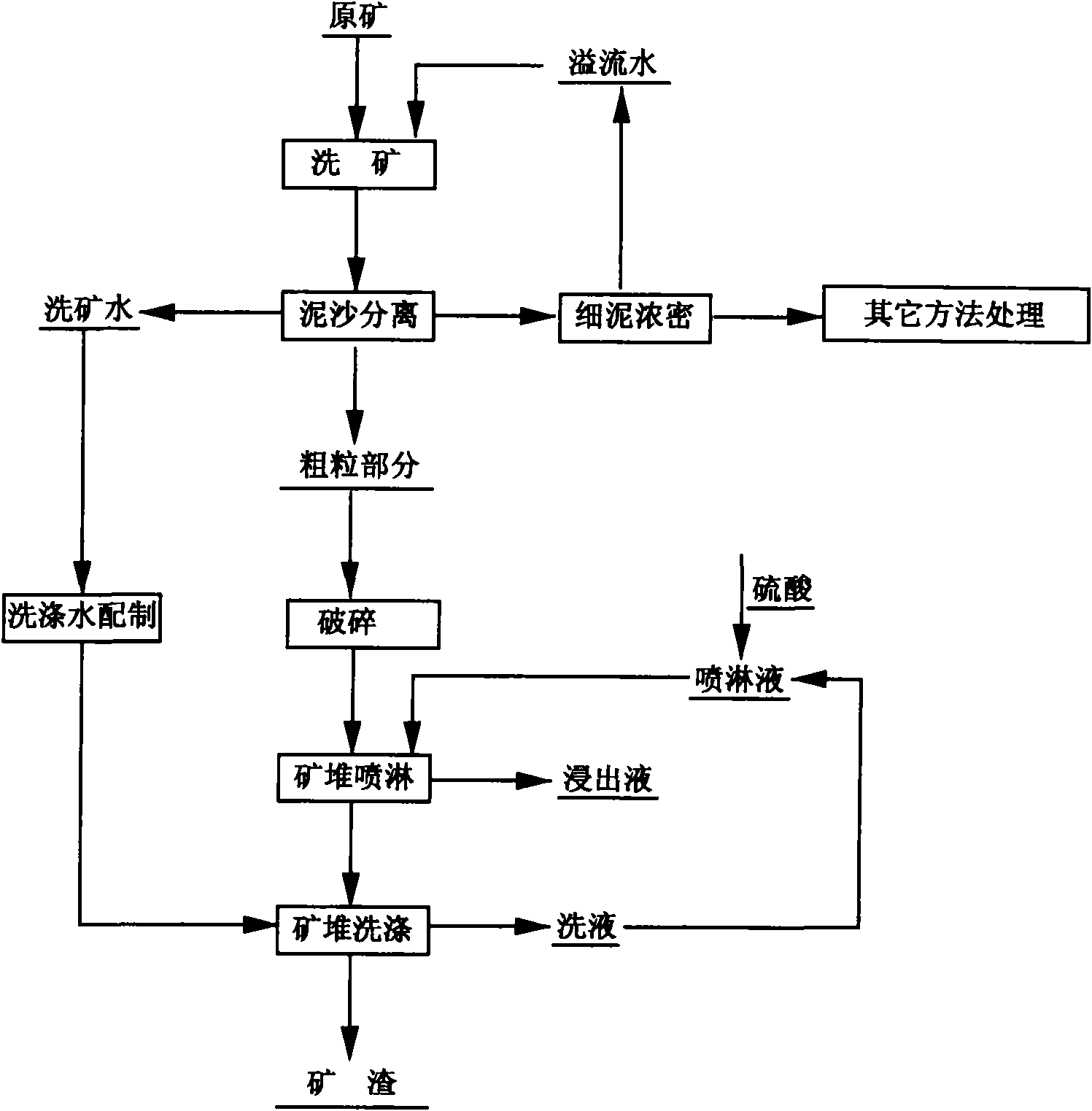

Method used

Image

Examples

Embodiment 1

[0046] A. Prepare the collected ore sample and the dense overflow water of fine mud according to the liquid-solid ratio of 1.5:1, wash the ore in the ore washing equipment for 60 minutes, and then pass through a 0.22mm sieve;

[0047] B. Use a jaw crusher to crush the ore samples with a particle size greater than 0.22mm on the sieve until the particle size is less than 20mm;

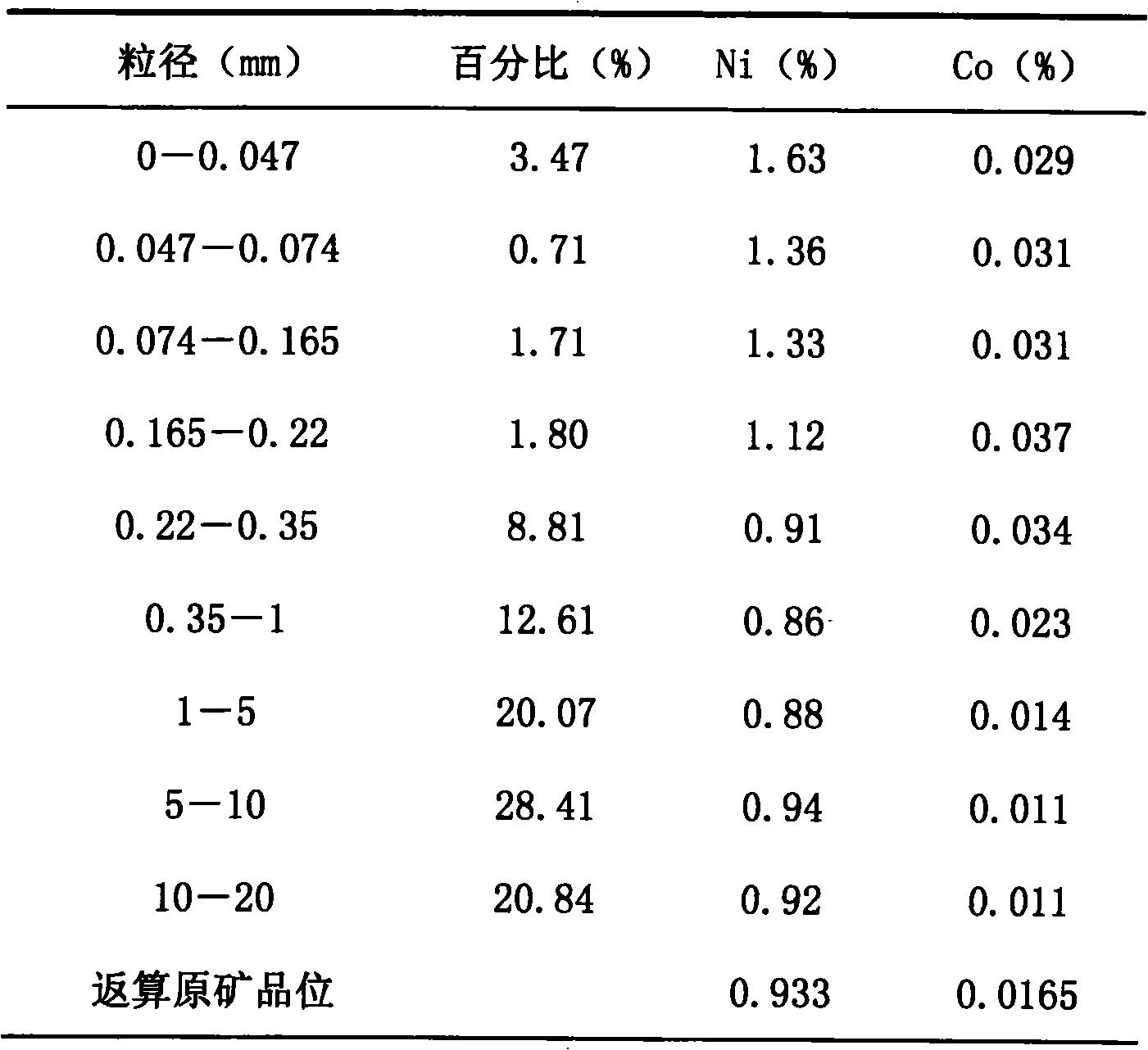

[0048] C. After crushing, the ore is mixed evenly and put into the pile. Get part and carry out particle size sieve analysis, the result is as shown in table 1;

[0049] D. The first batch of ore piles use tap water and sulfuric acid to prepare the spray liquid. The concentration of sulfuric acid in the first spray is 7%, the liquid-solid ratio is 1.5:1, and the spray intensity is 15L / m 2 h, after the first spraying, the expensive spraying liquid returns to the circular spraying and leaching after adding sulfuric acid, a total of four cycles, and the sulfuric acid is added to the circulating spraying li...

Embodiment 2

[0062] A. Prepare the collected ore sample and the dense overflow water of fine mud according to the liquid-solid ratio of 1.5:1, wash the ore in the ore washing equipment for 60 minutes, and then pass through a 0.22mm sieve;

[0063] B. Use a jaw crusher to crush the ore samples with a particle size greater than 0.22mm on the sieve until the particle size is less than 5mm;

[0064] C. After crushing, the ore is mixed evenly and put into the pile;

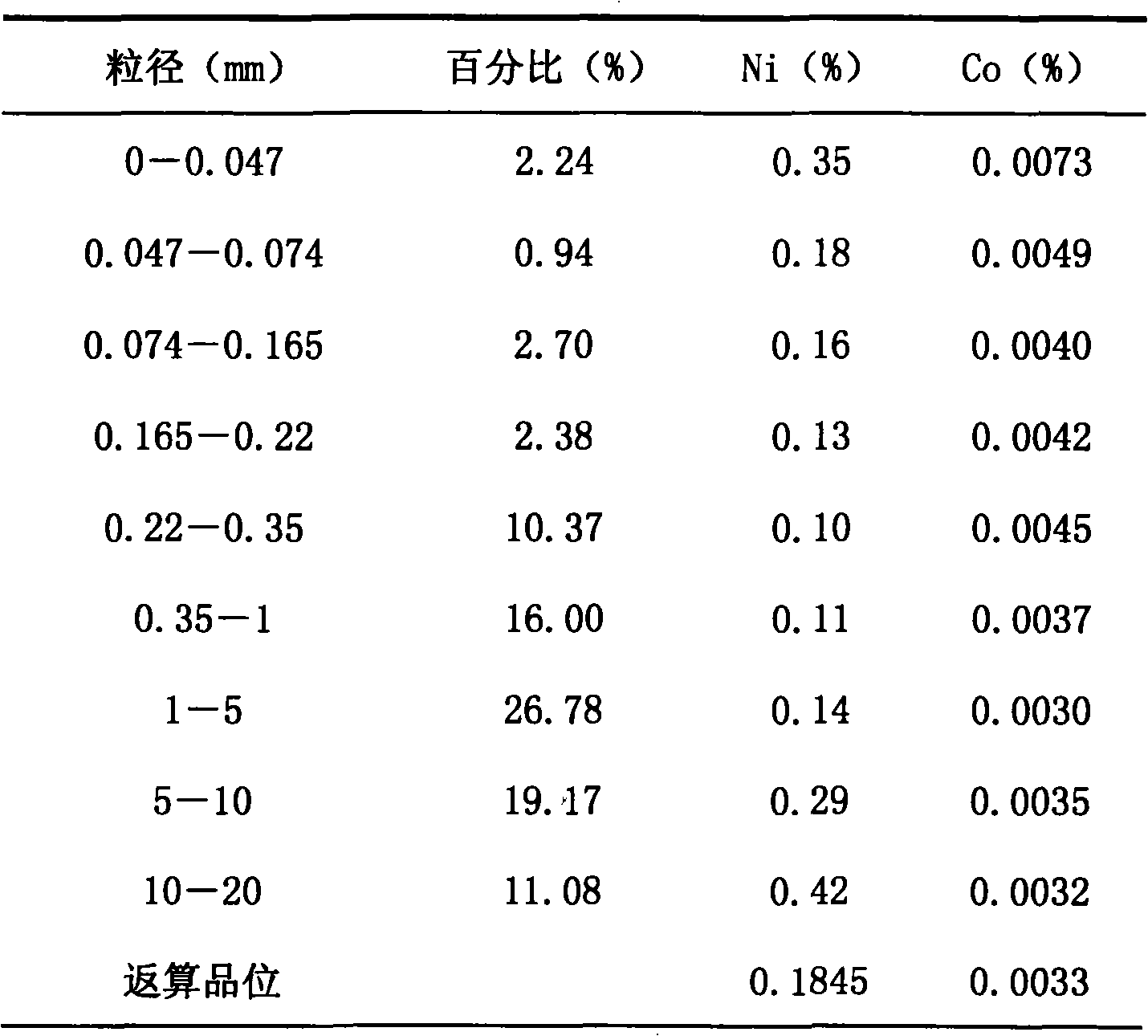

[0065] D. Use ore heap washing water and sulfuric acid to prepare spray liquid. The concentration of sulfuric acid in the first spray is 7%, the liquid-solid ratio is 1.5:1, and the spray intensity is 15L / m 2 h, after the first spraying, the expensive spraying liquid returns to the circular spraying and leaching after adding sulfuric acid, a total of four cycles, and the sulfuric acid is added to the circulating spraying liquid in four equal parts according to the amount of 600kg / t ore, and the cycle After spraying, the precious l...

Embodiment 3

[0071] A. Prepare the collected ore sample and the dense overflow water of fine mud according to the liquid-solid ratio of 1.5:1, wash the ore in the ore washing equipment for 60 minutes, and then pass through a 0.22mm sieve;

[0072] B. Use a jaw crusher to crush the ore samples with a particle size greater than 0.22mm on the sieve until the particle size is less than 40mm;

[0073] C. After crushing, the ore is mixed evenly and put into the pile;

[0074] D. Use ore heap washing water and sulfuric acid to prepare spray liquid. The concentration of sulfuric acid in the first spray is 14%, the liquid-solid ratio is 1.5:1, and the spray intensity is 4L / m 2 h, after the first spraying, the expensive spraying liquid returns to the circulating spraying and leaching after adding sulfuric acid, and the total cycle is twice, and the sulfuric acid is added to the circulating spraying liquid in two equal parts according to the amount of 600kg / t ore, and the circulating After spraying,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com